Chemical reaction kettle

A chemical reaction and reaction device technology, applied in the field of reaction devices, can solve the problems of low product yield, difficult temperature control, uneven gas-liquid contact, etc., to improve production efficiency and product quality, increase area and opportunities, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

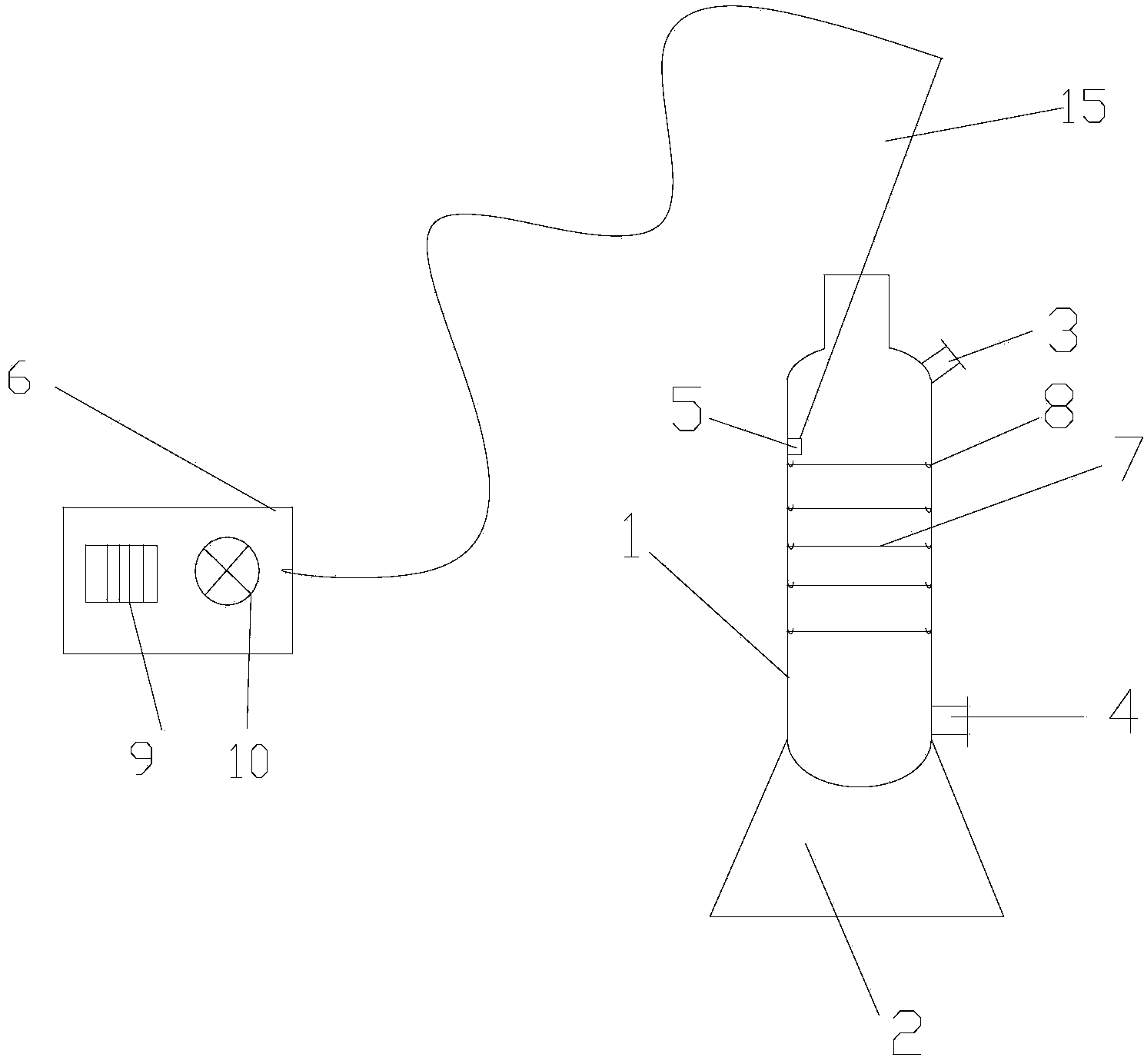

[0012] A chemical reaction kettle, comprising a kettle body 1 and a bracket 2, the upper and lower ends of the kettle body 1 are respectively provided with a feed inlet 3 and a discharge port 4, and a temperature sensor 5 is arranged in the kettle body 1, and the The temperature sensor 5 is electrically connected to the temperature controller 6 arranged outside the kettle body 1, at least three layers of gas-liquid contact reaction devices 7 are arranged in the kettle body 1, and several The hook 8, the gas-liquid contact reaction device 7 is movably connected to the corresponding hook 8. The gas-liquid contact reaction device 7 has five layers. The temperature controller 6 includes a temperature display unit 9 and a temperature control unit 10 .

[0013] The invention has a simple structure, and the operator can easily adjust the temperature of the reactor according to the signal transmitted by the temperature sensor to the temperature controller, and the gas-liquid contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com