High polymer self-adhesive glue film waterproof roll adopting pre-laid stick side up construction method and production method of roll

A self-adhesive film and waterproof membrane technology, applied in the field of building waterproof materials, can solve the problems of low strength, short service life, hidden dangers, etc., and achieve excellent weather resistance, long service life, and the effect of solving leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

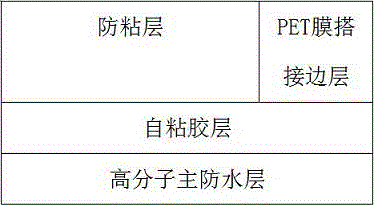

[0031] 1. Preparation of the main polymer waterproof layer

[0032] Take a thermoplastic polyolefin (TPO) film, and produce a homogeneous polymer membrane with a thickness of 0.7 mm through an extruder and a calender, as the main polymer waterproof layer.

[0033] 2. Preparation of the Self-Adhesive Adhesive Layer

[0034] The acrylic hot-melt pressure-sensitive adhesive is evenly coated on the surface of the polymer coil by an automatic glue applicator, and the thickness of the self-adhesive layer is 0.25-0.30 mm.

[0035] 3. Preparation of anti-adhesive layer

[0036] Apply white cement artificial sand evenly on the surface of the self-adhesive layer, leave 80-100mm overlapping edge on one longitudinal side, and the overlapping edge is not covered with sand;

[0037] 4. Preparation of lapping edge layer of PET film

[0038] The self-adhesive glue at the overlapping edge is covered with a PET transparent release film, the width of the release film is 80mm, and the roll mat...

Embodiment 2

[0040] 1. Preparation of the main polymer waterproof layer

[0041] Take a thermoplastic polyolefin (TPO) film, and produce a homogeneous polymer membrane with a thickness of 1.0 mm through an extruder and a calender, as the main polymer waterproof layer.

[0042] 2. Preparation of the Self-Adhesive Adhesive Layer

[0043] The acrylic hot-melt pressure-sensitive adhesive is evenly coated on the surface of the polymer coil by an automatic glue applicator, and the thickness of the self-adhesive layer is 0.26mm.

[0044] 3. Preparation of anti-adhesive layer

[0045] Apply white cement artificial sand evenly on the surface of the self-adhesive layer, leaving 85mm overlapping edges on one side in the longitudinal direction, and the overlapping edges are not covered with sand;

[0046] 4. Preparation of lapping edge layer of PET film

[0047] The self-adhesive glue at the overlapping edge is covered with a PET transparent release film, the width of the release film is 80mm, and ...

Embodiment 3

[0049] 1. Preparation of the main polymer waterproof layer

[0050] Take a high-density polyethylene (HDPE) film, and produce a homogeneous polymer membrane with a thickness of 1.2mm through an extruder and a calender, as the main polymer waterproof layer.

[0051] 2. Preparation of the Self-Adhesive Adhesive Layer

[0052] The acrylic hot-melt pressure-sensitive adhesive is evenly coated on the surface of the polymer coil by an automatic glue applicator, and the thickness of the self-adhesive layer is 0.28mm.

[0053] 3. Preparation of anti-adhesive layer

[0054] Apply white cement artificial sand evenly on the surface of the self-adhesive layer, leave a 95mm overlapping edge on one longitudinal side, and the overlapping edge is not covered with sand;

[0055] 4. Preparation of lapping edge layer of PET film

[0056] The self-adhesive glue at the overlapping edge is covered with a PET transparent release film, the width of the release film is 80mm, and the roll material o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com