Steam back-flow preventer for brewing machine

A backflow prevention device and wine steam technology, applied in the field of winemaking, can solve the problems of lowering wine quality, easy steam backflow, affecting the distillation effect, etc., and achieve the effect of preventing the backflow of wine steam, avoiding the leakage of wine steam, and ensuring the distillation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

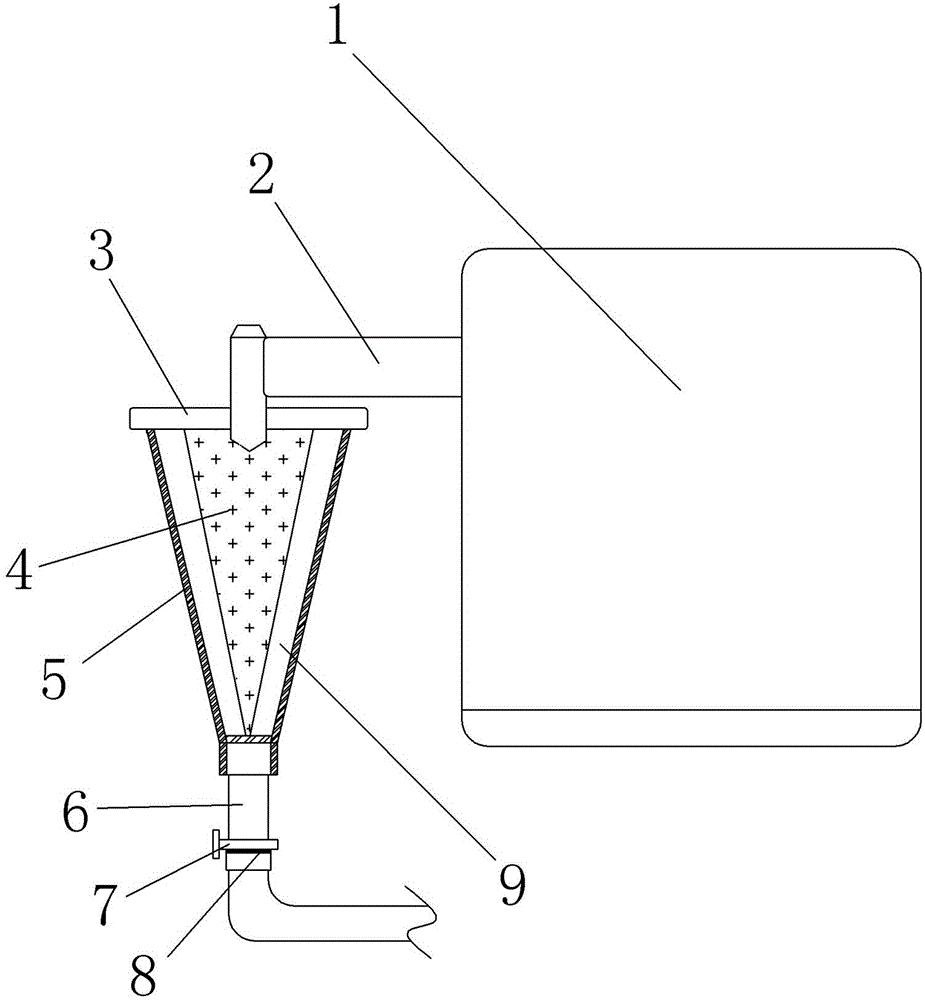

[0014] Such as figure 1 As shown: the present invention provides a steam backflow prevention device for a wine brewing machine, which includes a wine steam pipeline 2 connected to the upper part of the distillation device 1, the wine steam pipeline 2 is connected with a conical shell 5, and the conical shell 5 The section away from the 2 ends of the wine steam pipeline gradually decreases; the inside of the conical housing 5 is set as a cavity, and the inner wall of the conical housing 5 is provided with a cushion layer 9, and the cavity is filled with absorbent cotton 4 to absorb The cotton 4 is made of water-absorbing edible fiber material, the other end of the conical housing 5 is connected to a guide tube 6, and a one-way valve 7 is arranged on the guide tube 6, and the one-way valve 7 is provided with a one-way diaphragm 8. The win...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com