Steel wire pickling device

A pickling device and steel wire technology, applied in the field of steel wire production equipment, can solve the problems of dripping on the ground, incomplete pickling, waste of acid, etc., to accelerate contact speed, ensure thorough pickling, and strengthen sealing performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

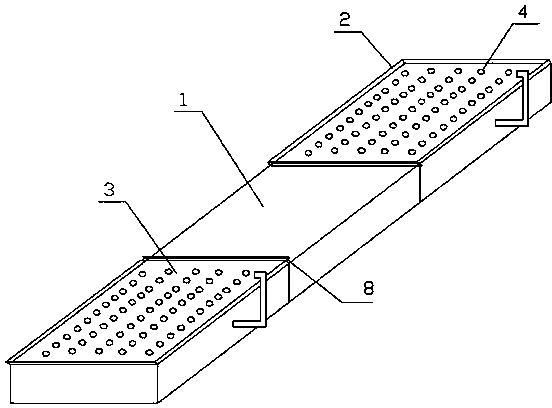

[0026] This embodiment includes a pickling tank 1 and a water washing tank 2. There are two washing tanks 2. The pickling tank 1 is between the two washing tanks 2. The water washing tank 2 is provided with a cover plate 3, and the cover plate 3 is provided with A plurality of leakage holes 4 are arranged, and a water pump is arranged in the water washing tank, and the water inlet end of the water pump is arranged on the bottom of the water washing tank, and the water outlet end of the water pump is arranged on the cover plate 3 of the water washing tank.

Embodiment 2

[0028] This embodiment includes a pickling tank 1 and a water washing tank 2. There are two washing tanks 2. The pickling tank 1 is between the two washing tanks 2. The water washing tank 2 is provided with a cover plate 3, and the cover plate 3 is provided with A plurality of leakage holes 4 are arranged, and a water pump is arranged in the water washing tank, and the water inlet end of the water pump is arranged on the bottom of the water washing tank, and the water outlet end of the water pump is arranged on the cover plate 3 of the water washing tank.

[0029] The shape of the water leakage hole 4 is trumpet-shaped, and the trumpet-shaped water leakage hole 4 can increase the strength when the water is discharged to obtain a better washing effect.

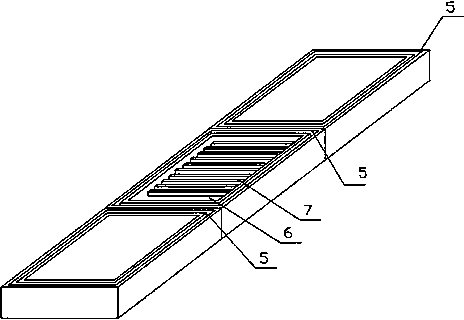

[0030] A sealing groove 5 is arranged around the top of the washing tank 2, and the sealing groove is filled with water, and the surrounding edges of the cover plate are covered in the sealing groove.

Embodiment 3

[0032] This embodiment includes a pickling tank 1 and a water washing tank 2. There are two washing tanks 2. The pickling tank 1 is between the two washing tanks 2. The water washing tank 2 is provided with a cover plate 3, and the cover plate 3 is provided with A plurality of leakage holes 4 are arranged, and a water pump is arranged in the water washing tank, and the water inlet end of the water pump is arranged on the bottom of the water washing tank, and the water outlet end of the water pump is arranged on the cover plate 3 of the water washing tank.

[0033] A sealing groove 5 is arranged around the top of the washing tank 2, and the sealing groove 5 is filled with water, and the surrounding edges of the cover plate 3 are covered in the sealing groove.

[0034] The top of pickling tank is also provided with sealing groove 5 around, and water is filled in sealing groove 5, and the top of pickling tank is provided with lid, and the peripheral edge of lid is positioned at se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com