Residual gas recovery process

A technology of residual gas and technology, which is applied in the field of recovery and reuse of vehicle-mounted residual natural gas, can solve the problems of waste of resources, unfavorable environmental protection, etc., and achieve the effects of saving energy, benefiting environmental protection, and reducing manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

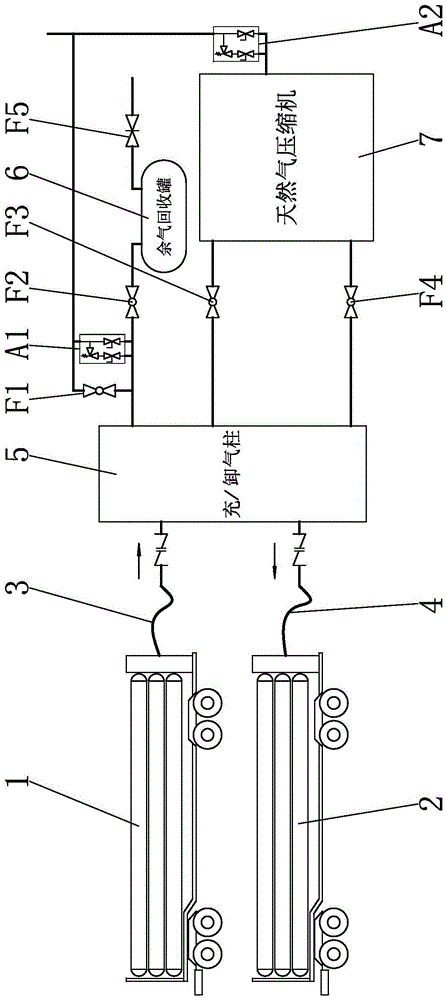

[0008] A residual gas recovery process, such as figure 1 As shown, including the residual gas recovery device used in this process, the residual gas recovery device includes an unloading hose 3, an inflation hose 4, a charging / unloading column 5, a residual gas venting valve F1, a residual gas recovery valve F2, Empty pipeline, residual gas recovery tank 6, residual gas discharge valve F5, inlet valve F3, gas outlet valve F4, natural gas compressor 7, first safety valve A1 and second safety valve A2; The unloading column 5 is connected to the inflation hose 4, the unloading hose 3 or both the unloading hose 3 and the inflation hose 4 are connected to the residual air release valve F1, the first safety valve A1 and the first safety valve A1 through the charging / unloading column 5 The residual gas recovery valve F2, the residual gas venting valve F1 and the first safety valve A1 are connected to the venting pipeline at the same time, the residual gas recovery valve F2 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com