Central air-conditioner chilled water control method based on dynamic response to tail-end total load changes

A control method and central air-conditioning technology, applied in the direction of heating and ventilation control systems, applications, heating methods, etc., can solve the problems of control failure, affecting the rapidity and stability of the system, and poor accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

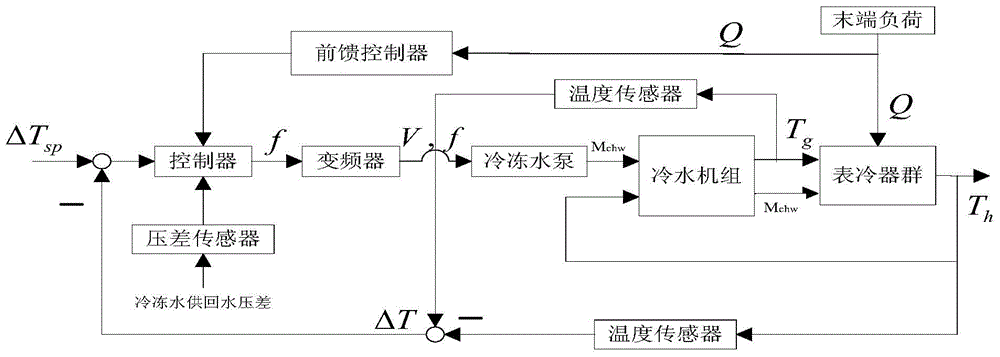

[0100] combine figure 1 with figure 2 , a central air-conditioning chilled water control method based on the dynamic response to the change of the total load at the end:

[0101] a1: The first temperature sensor collects the temperature T of the chilled water supply g , the second temperature sensor collects the temperature T of the chilled water return water h , calculate the chilled water supply and return water temperature difference ΔT = T g -T h ;Set chilled water supply and return water temperature difference setting value ΔT sp ;Calculate the set value of the chilled water supply and return water temperature difference ΔT sp The difference with the chilled water supply and return water temperature difference ΔT, the difference is sent to the controller;

[0102] a2: The pressure difference sensor collects the pressure difference ΔP of the chilled water supply and return; set the minimum pressure difference of the chilled water supply and return to ΔP sp ;Calcula...

Embodiment 2

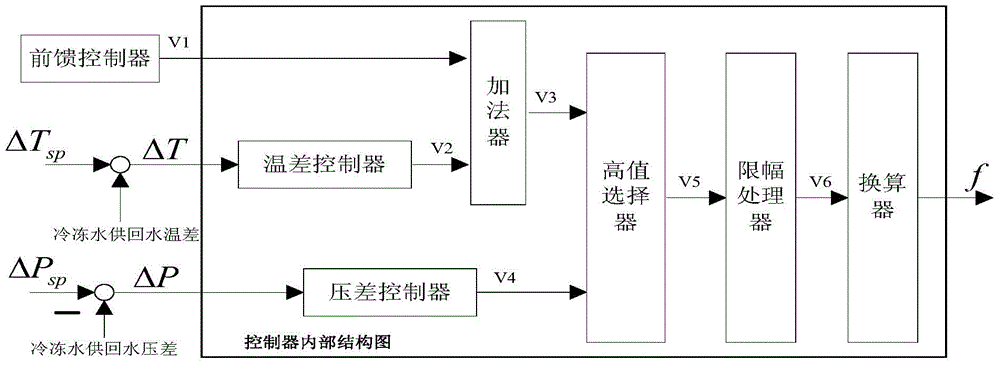

[0109] Based on the method described in Embodiment 1, the controller includes a temperature difference controller, a pressure difference controller, an adder, a high value selector, a limiter processor, and a converter, and the control strategy is:

[0110] 1) The temperature difference processor sets the temperature difference ΔT for the chilled water supply and return water sp Process the difference with the temperature difference ΔT of the chilled water supply and return water to obtain the output v2;

[0111] 2) The adder adds the output v2 and the output v1 of the feedforward controller to obtain the output v3;

[0112] 3) The differential pressure sensor sets the minimum differential pressure ΔP for chilled water supply and return water sp Calculate the difference between the pressure difference ΔP and the chilled water supply and return water to obtain the output v4;

[0113] 4) The high value selector selects the larger one of output v3 and output v4 as output v5;

...

Embodiment 3

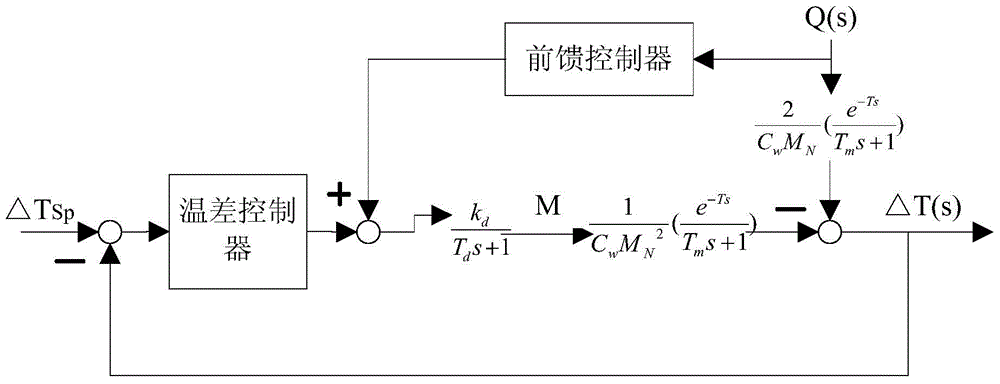

[0117] Based on the method described in embodiment 1, the transfer function of the feedforward controller is G ff :

[0118] G ff = 2 k d M N e - Ts ( T m s + 1 ) ( T d s + 1 )

[0119] The physical meaning represented by the letters in the formula:

[0120] In the frequency converter and cold pump water pump system,

[0121] M = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com