Vacuum drying mixer used for soft magnetic raw materials

A vacuum drying and mixer technology, which is applied in mixer accessories, non-progressive dryers, mixers with rotary mixing devices, etc. Quality, thorough mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

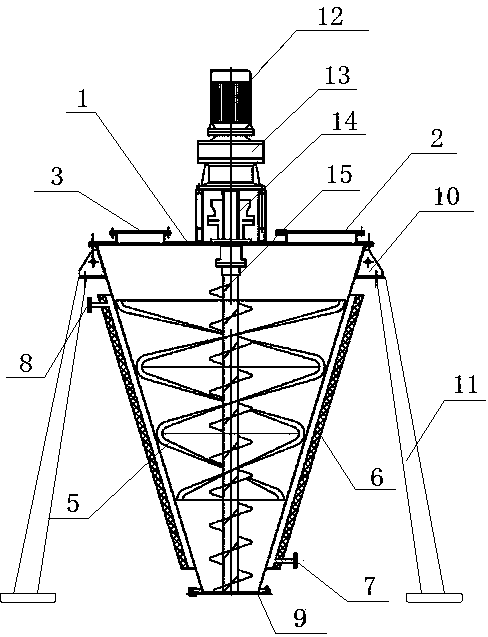

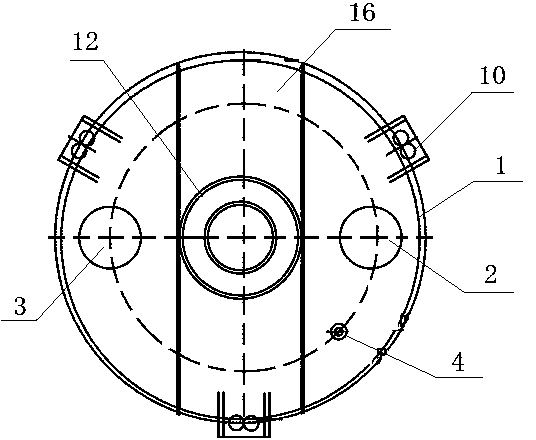

[0016] Such as figure 1 , 2 A vacuum drying mixer for soft magnetic raw materials is shown, including: a drying mixer body 1, a powder inlet 2, a powder outlet 9, an air inlet 3, a transmission assembly, a vacuum port 4, and a stirring blade 5; It is characterized in that: the dry mixer body 1 is an inverted cone body, and the inverted cone body is covered with a double-layer hollow jacket body 6, and a hot and cold water inlet 7 and a hot and cold water outlet are arranged on the double-layer hollow jacket body 6 8; the powder inlet 2, the air inlet 3, the transmission assembly and the vacuum port 4 are all installed on the upper end surface of the dry mixer body 1; the powder outlet 9 is installed on the lower end surface of the dry mixer body 1; Stirring blade 5 is installed on the transmission assembly.

[0017] The dry mixer body 1 is an inverted conical frustum, and is connected with a bracket 11 through three supporting angle steels 10 uniformly distributed on the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com