System for realizing automatic detection of electronic glass defects

A technology for automatic detection of glass defects, applied in measuring devices, image data processing, material analysis through optical means, etc., can solve the problems of workers' easy visual fatigue, glass defect missed detection, low stability, etc., and improve detection accuracy and glass quality, reduce testing costs, and enhance the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

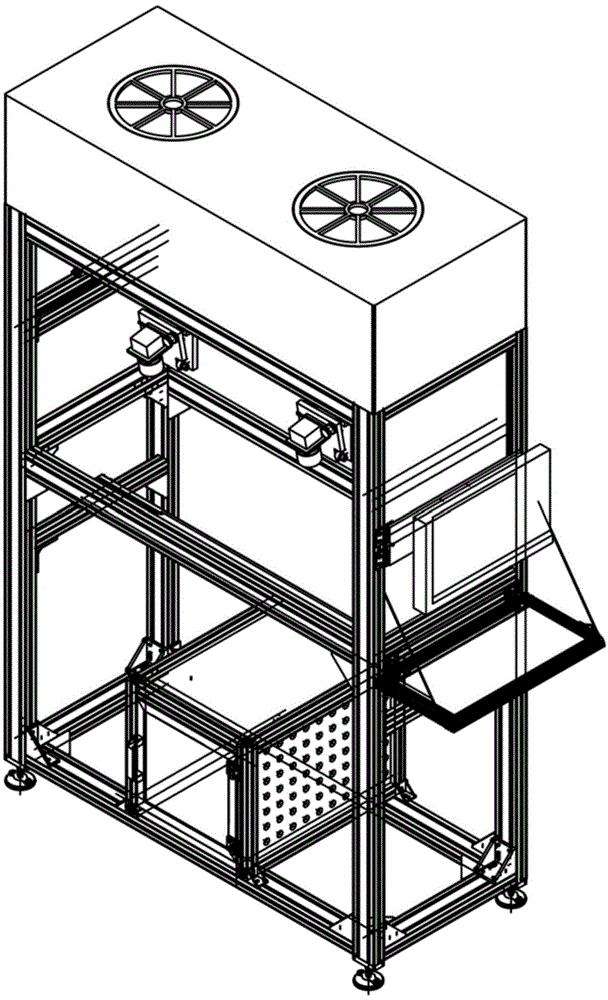

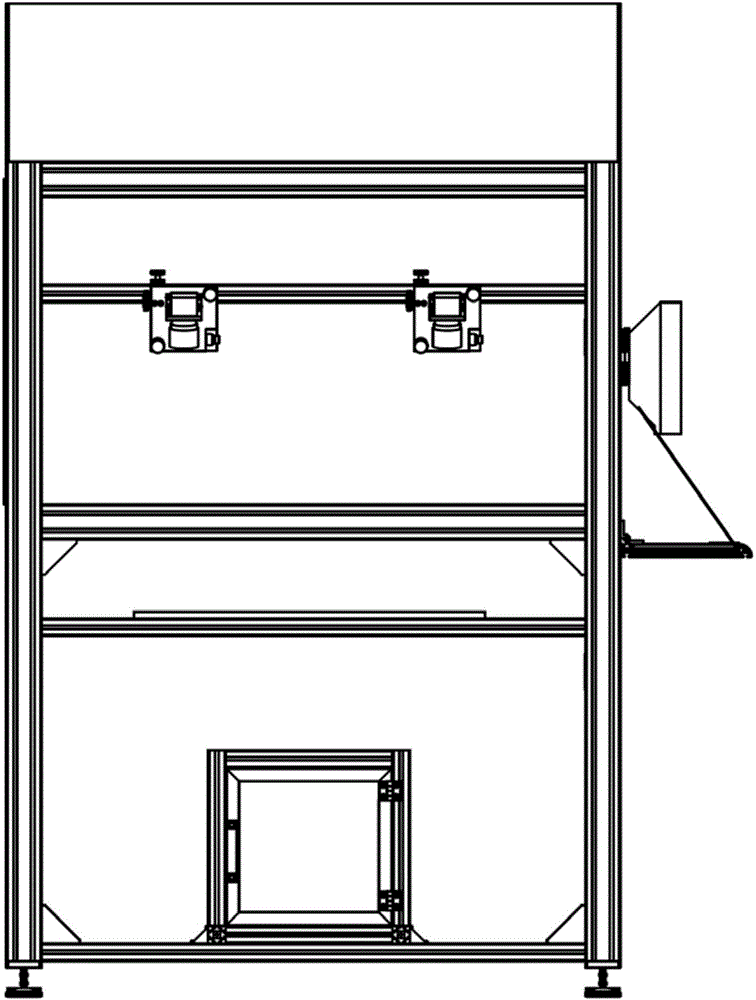

[0030] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

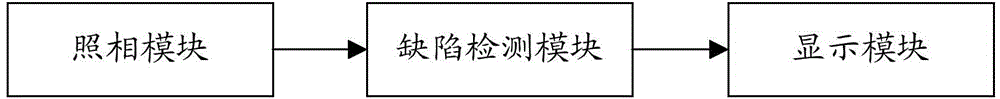

[0031] see figure 1 , in one embodiment, the system for realizing the automatic detection of electronic glass defects of the present invention includes:

[0032] camera module, in order to obtain the image of described electronic glass;

[0033] The defect detection module is used to obtain several segmented objects by analyzing the image of the electronic glass, and perform defect location processing and defect classification processing on each segmented object to obtain the defect type of each segmented object;

[0034] The display module is used for displaying the defect type information of each segmented object.

[0035] In a preferred embodiment, the defect detection module includes a defect classification unit, and the defect classification unit is used to calculate each of the segmented objects thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com