Transformer coil and winding method thereof and automatic winding machine

A technology of transformer coils and automatic winding machines, which is applied in the direction of transformer/inductor coil/winding/connection, coil manufacturing, etc., which can solve the problems of large coil outer diameter direction, waste of wires, low degree of automation, etc., and achieve reduction Overall dimensions, reduced prefabrication man-hours, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

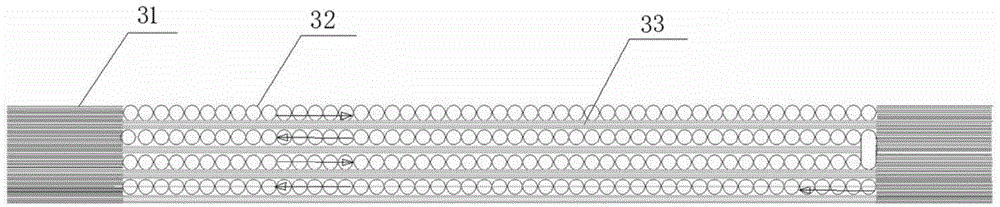

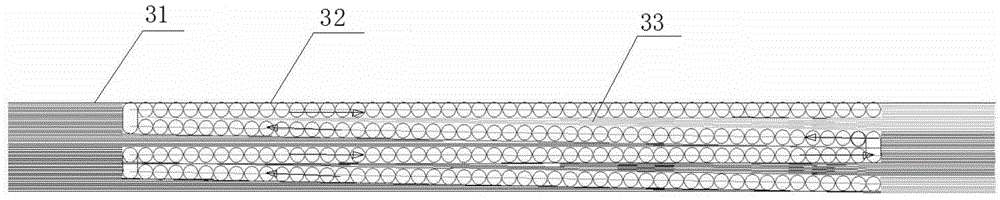

[0045] like figure 2 The embodiment of the present invention is a transformer coil, including the wire layer 33, the intervertebral insulation layer 32 between the two adjacent wire layers 33 and the end insulating layer 31, of which the thickness of the intervertebral insulation layer 32 follows the thickness of the layer 32.The voltage gradient of the two adjacent wire layer 33 increased and increased.The inter -layer insulation layer 32 and the end -end insulation layer 31 are made of stacking of the insulating paper belt, and the thickness of the thickness of the inter -layer insulation layer 32 changes with the turbine spacing of the insulator belt, and the thickness of the end insulation layer 31 is uniform.Among them, the intervertebral insulation layer 32 and end insulation layer 31 located on the same layer are made of continuous winding.

[0046]

Embodiment 2

[0048] The embodiment of the present invention provides a winding method of a transformer coil. The insulating layer is made of an insulation paper belt. The method of winding includes the following steps:

[0049] (1) Insulation paper belt first to complete the end -end insulation layer of the first elementary level;

[0050](2) Press the wires above the insulation paper belt. The two are winding at the same time.The end -insulation layer, cut off the insulation paper belt, the wire one -way winding of the wire to complete the wire layer;

[0051] (3) Continuous opposite winding of the wires, press the insulation paper belt below again, repeat the steps (2), and finally complete the end -layer intervertebral insulation layer, the end -end insulation layer and the last layer of the wire in turn.The layer is the transformer coil.

[0052] Among them, in the step (1), the insulation paper belt to the re -system to obtain the end -end insulating layer of the uniformity of the middle ...

Embodiment 3

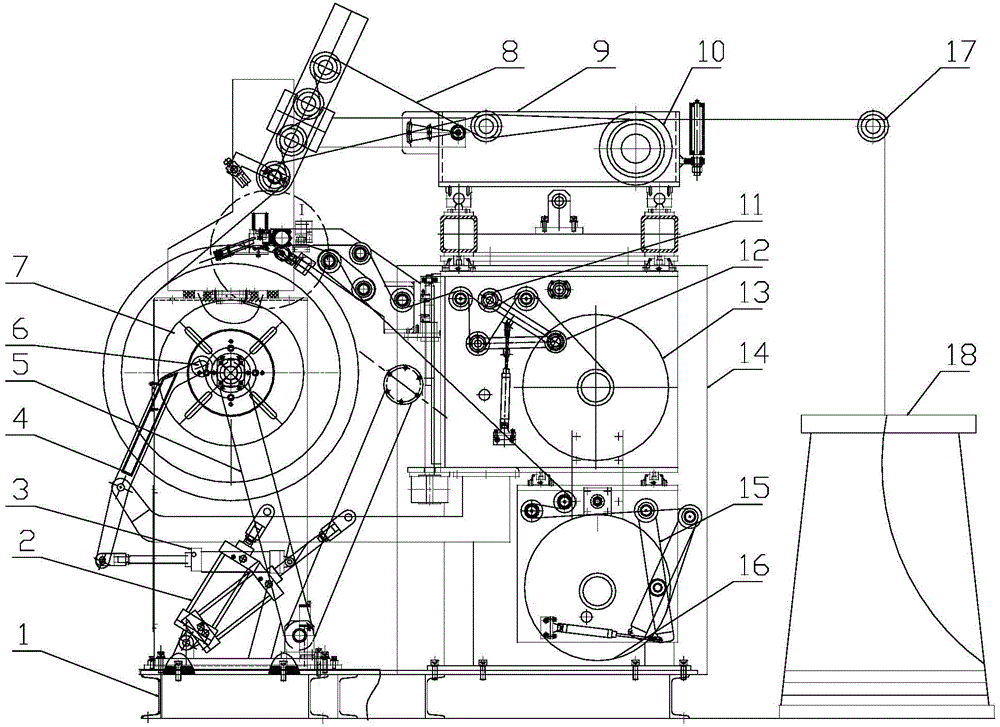

[0059] See image 3 As well as Figure 4 and Figure 5 , The present invention is an automatic winding machine, including the main axis 21 and the main axis of the driver's spindle 21 rotating the spindle of the main axis 21 with the spindle of the main axis.Motor 19 and the main axis reducer 20, the output shaft of the main axis reducer 20 drives the spindle 21; it also includes a wire winding mechanism set on the rack 1 and the insulating paper band winding mechanism.Linear driver mechanisms moved by block 9 and driving wires 9 horizontal moving. The wire activity block 9 is equipped with a wire plate 10 with a wire and a wire;14 High -level non -linear driver, insulation paper tape activity block 14 is set on the insulating paper band with insulating paper belt (the embodiments of the present invention include two insulation paper bands, insulation paper band A13 and insulation paper beltDisk B16); Insulation paper tape activity block 14 also has a pressure wheel mechanism that ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com