A transformer coil, its winding method and automatic winding machine

A technology of transformer coil and automatic winding machine, which is applied in the direction of transformer/inductor coil/winding/connection, inductor/transformer/magnet manufacturing, coil manufacturing, etc. and other problems, to achieve the effect of reducing the overall size, improving production efficiency, and saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

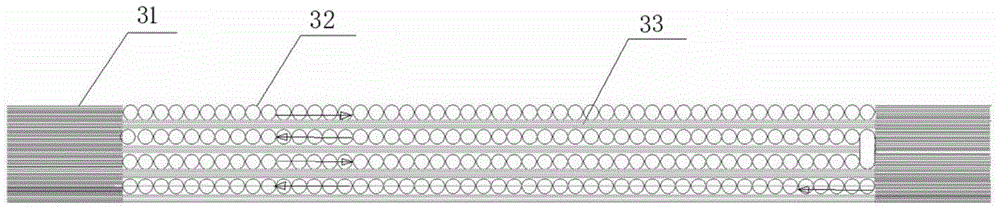

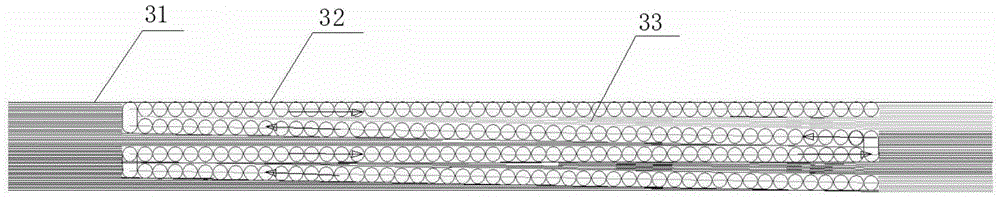

[0039] Such as figure 2 As shown, the embodiment of the present invention is a transformer coil, including a wire layer 33, an interlayer insulating layer 32 and an end insulating layer 31 located between two adjacent wire layers 33, wherein the thickness of the interlayer insulating layer 32 varies with The voltage gradient of the upper and lower adjacent two wire layers 33 increases and increases. The interlayer insulating layer 32 and the end insulating layer 31 are formed by stacking insulating paper tapes, and the thickness of the interlayer insulating layer 32 varies with the turn spacing of the insulating paper tape, and the thickness of the end insulating layer 31 is uniform. Wherein, the interlayer insulating layer 32 and the end insulating layer 31 located on the same layer are formed by continuous winding of insulating paper tape.

Embodiment 2

[0041] An embodiment of the present invention provides a method for winding a transformer coil. The insulating layer is formed by winding an insulating paper tape. The winding method includes the following steps:

[0042] (1) The insulating paper tape is first wound to complete the end insulating layer of the first layer at one end;

[0043] (2) Press the wire on the top of the insulating paper tape, and the two are wound at the same time. The insulating paper tape is stacked and wound and the unidirectional turn spacing is gradually reduced. After the stacked winding of the interlayer insulating layer is completed, the continuous reciprocating winding is completed. Cut off the insulating paper tape for the end insulation layer, and wind the wire in a single layer in one direction to complete the wire layer;

[0044] (3) The wires are continuously wound in reverse, and the insulating paper tape is pressed down again, and step (2) is repeated, and finally the interlayer insulat...

Embodiment 3

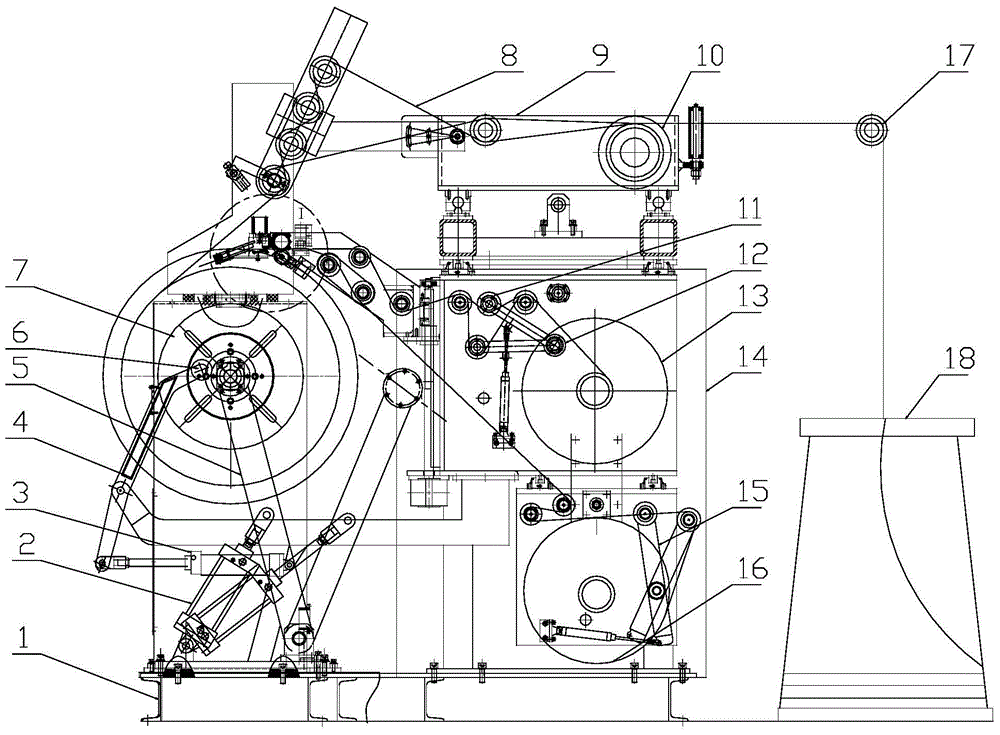

[0051] see image 3 , Figure 4 and Figure 5 , the present invention is an automatic winding machine, comprising a frame 1, a main shaft 21 arranged on the frame 1 and a main shaft driving device for driving the main shaft 21 to rotate, the main shaft 21 is provided with a winding die 7, and the main shaft driving device comprises a main shaft The motor 19 and the main shaft reducer 20, the output shaft of the main shaft reducer 20 drives the main shaft 21 to rotate; it also includes a wire winding mechanism and an insulating paper tape winding mechanism arranged on the frame 1, and the wire winding mechanism includes a wire movable The block 9 and the linear drive mechanism that drives the wire movable block 9 to move horizontally, the wire movable block 9 is provided with a wire coil 10 wrapped with wires; the insulating paper tape winding mechanism includes an insulating paper tape movable block 14 and a drive insulating paper tape movable block 14. Non-linear drive mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com