Multi-direction wideband energy harvesting device based on vibration friction

A vibration friction and energy collection technology, applied in the direction of friction generators, etc., can solve the problems of inability to achieve self-supply, mechanical collision energy loss, complex structure, etc., to improve energy conversion efficiency, reduce mechanical energy loss, and have a wide range of applications. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with drawings and embodiments.

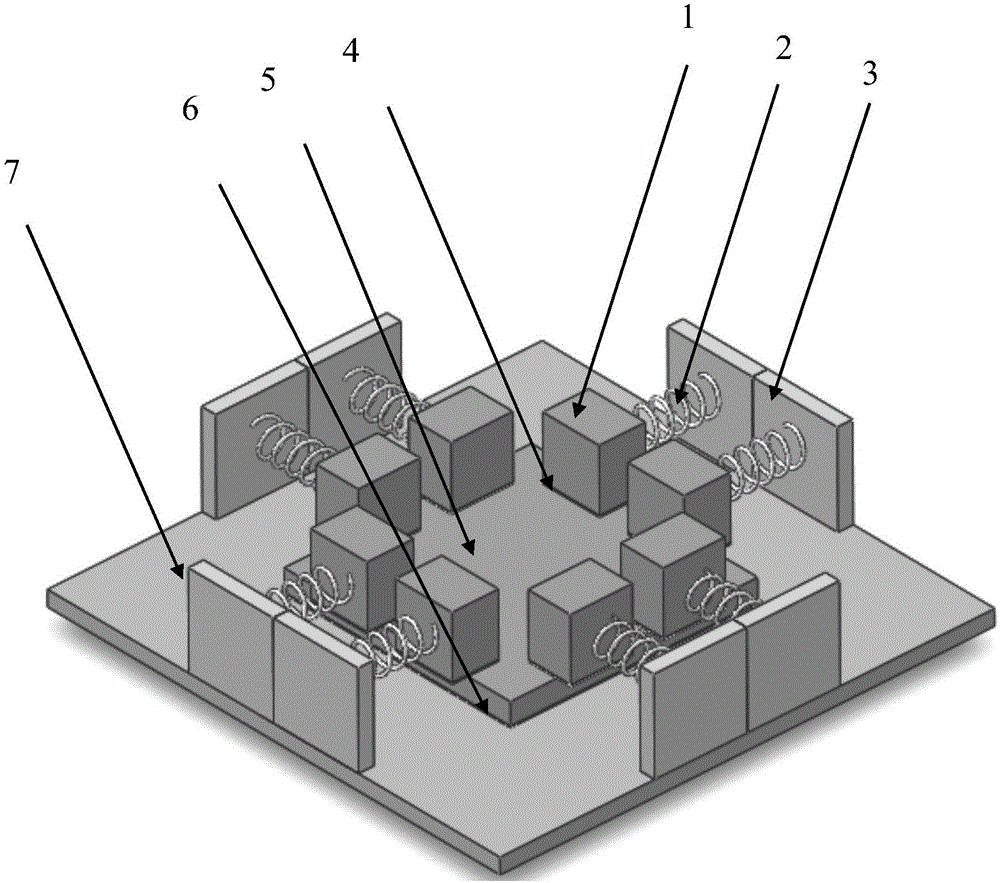

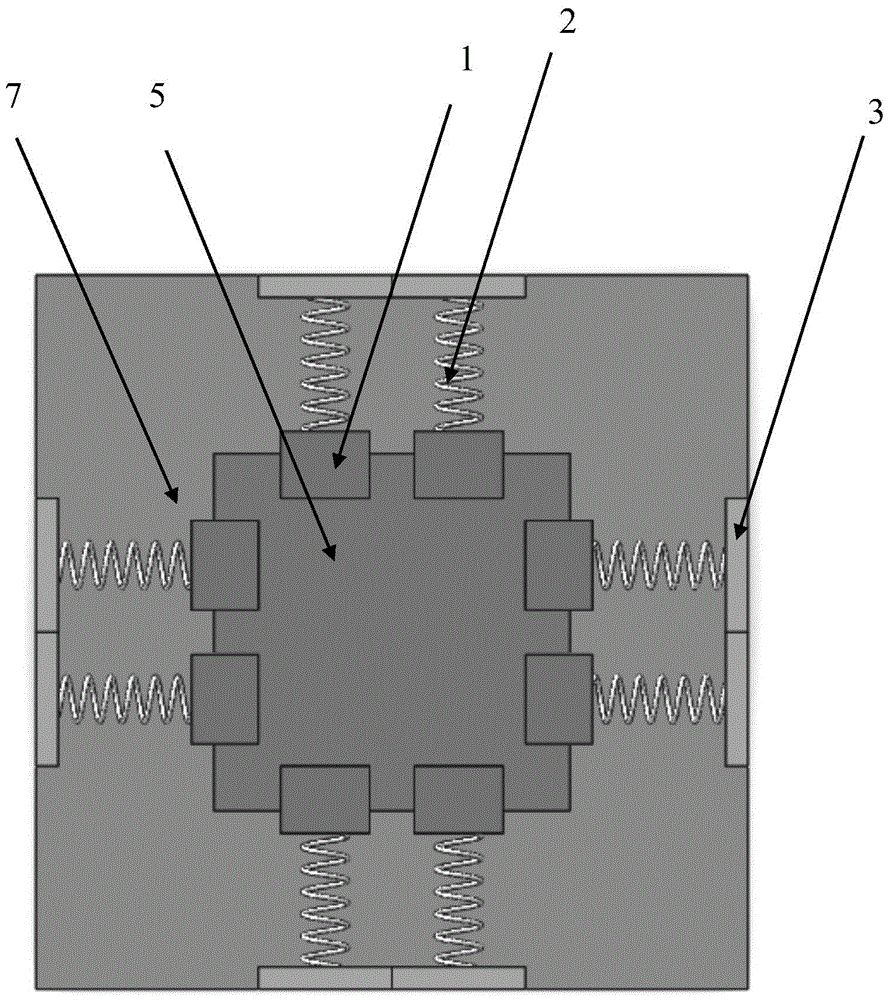

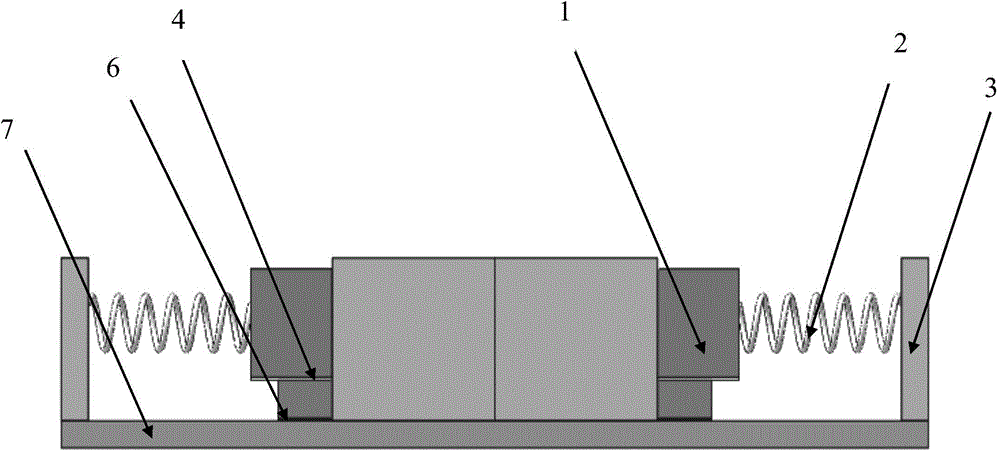

[0026] Ruhe figure 1 As shown, the present invention provides a multi-directional broadband energy harvesting device based on vibration and friction, including a mass block 1, a spring 2, a fixed baffle 3, an upper electrode 4, a friction base 5, a lower electrode 6, and a base 7. In the example, one side of the mass block 1 is connected to one end of the spring 2; the other section of the spring 2 is connected to the fixed baffle 3 to form an elastic vibration device, and it is placed horizontally and fixed around the base 7. The number of the elastic vibration devices Two in each direction. The masses of the masses between different elastic vibrating devices are not the same. The upper electrode 4 is arranged on the lower surface of the mass block 1; the upper surface of the friction base 5 is in contact with the upper electrode 4; the contact area between the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com