Device for joining ends of pipes made of steel by means of orbital welding

A technology of orbital welding and welding parts, applied in the field of end devices, can solve the problems of complicated welding process and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

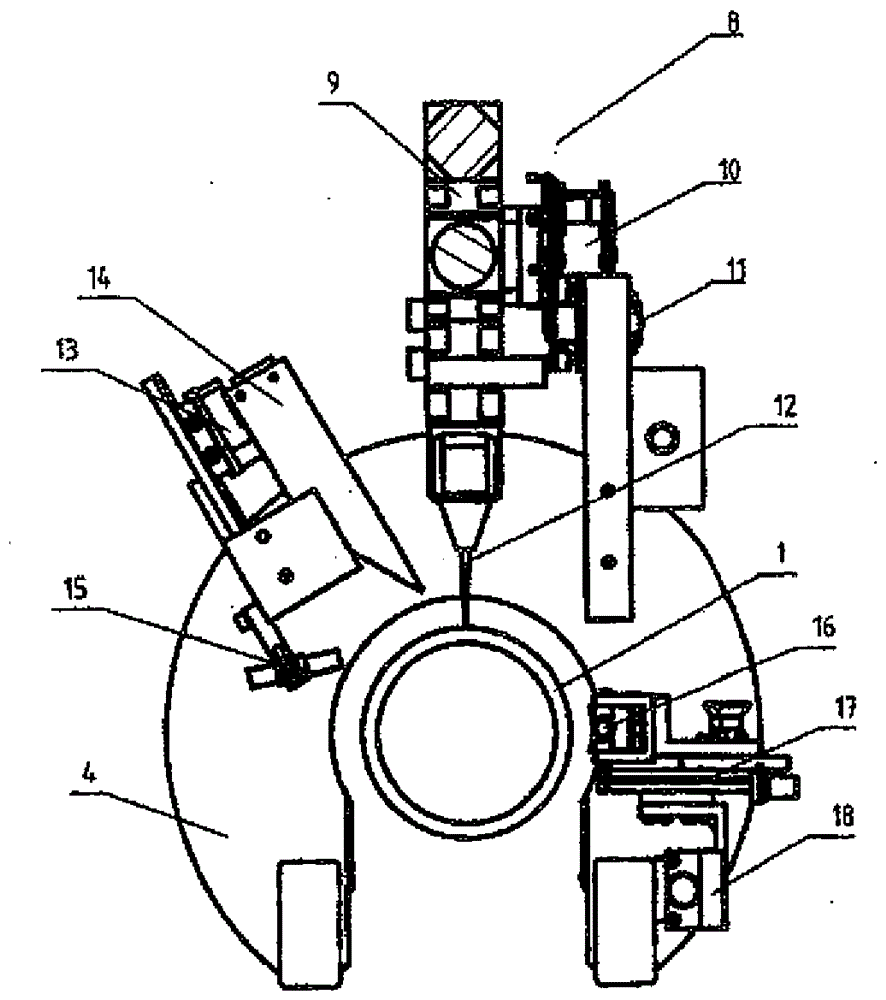

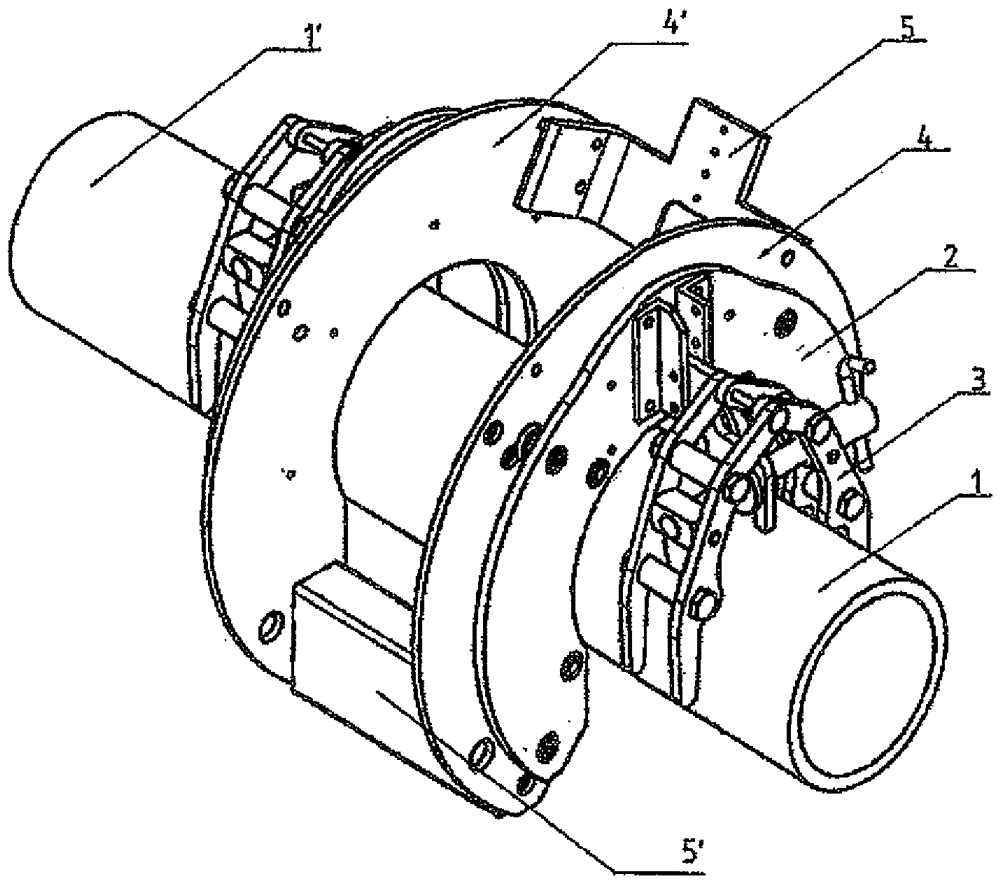

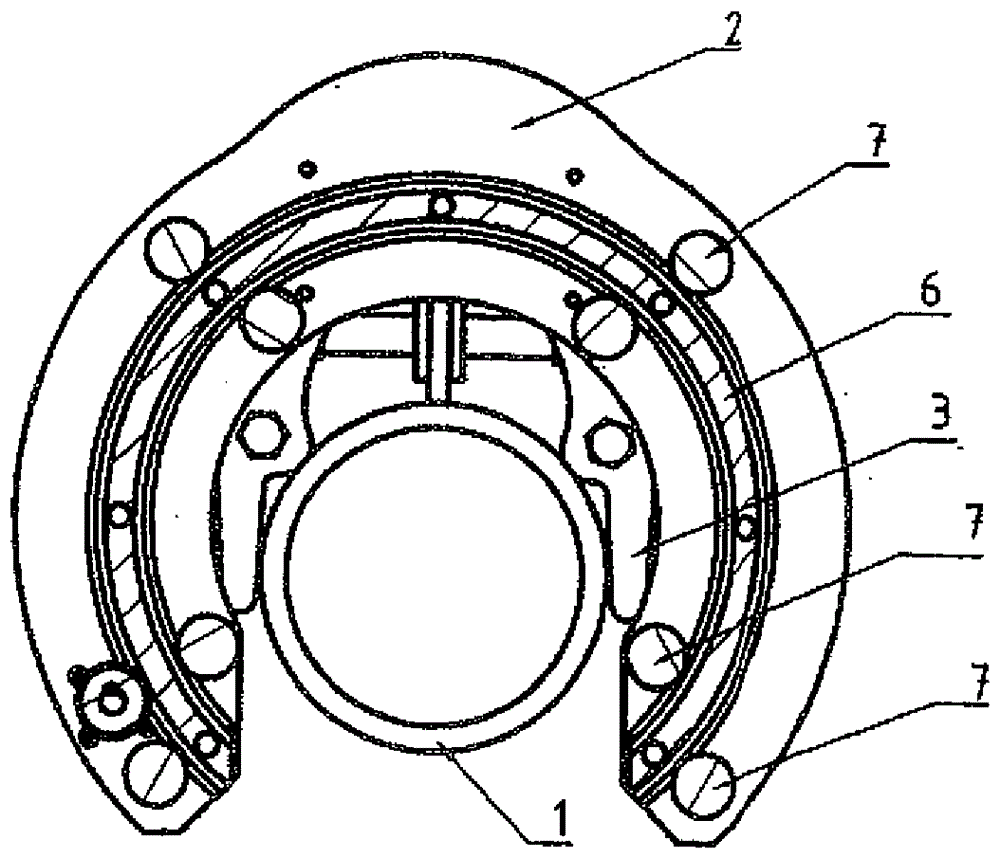

[0025] figure 1 The basic structure of the device according to the invention is described. It consists of two annular guide base plates 2 provided with radial openings in order to be able to place them on the pipes 1 , 1 ′ to be joined. The diameter of the inner ring is greater than the diameter of the tubes 1 , 1 ′ to be welded, so that the centering of the welding and testing tool can be precisely corrected by radial play. In order to fix the device on the ends of the tubes 1, 1', clamping elements 3 are mounted on the outside of the guide base plates 2 facing away from the welding joint, with which the two guide base plates 2 are each connected to a tube end. Clamped by clamping element 3 .

[0026] On the inner side of the guide base plate 2 facing the weld joint, a circular swivel hoop 4, 4', which is likewise provided with radial openings, is guided in a rotationally mounted manner, so that it can be carried out around the pipe 1, 1' along the Guide the circular motio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com