Special equipment for girth welding and its application

A special equipment and girth welding technology, which is applied in welding equipment, welding equipment, arc welding equipment, etc., can solve the problems of high welding cost and hidden dangers of welding quality, so as to improve production efficiency, reduce production cost and high welding quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

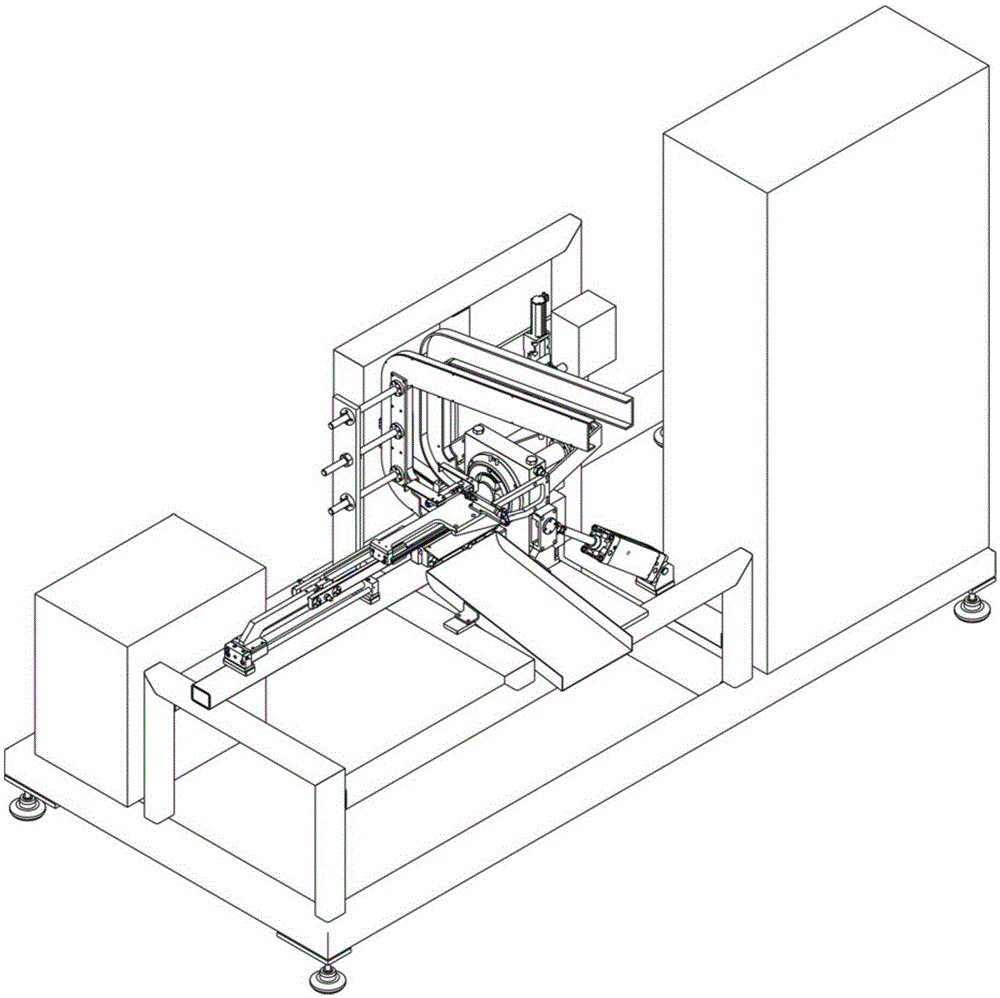

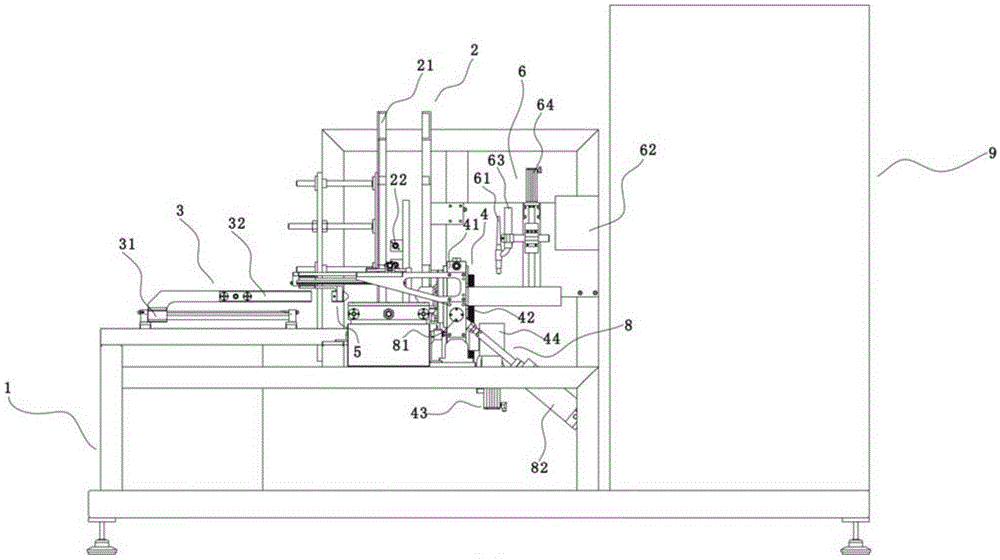

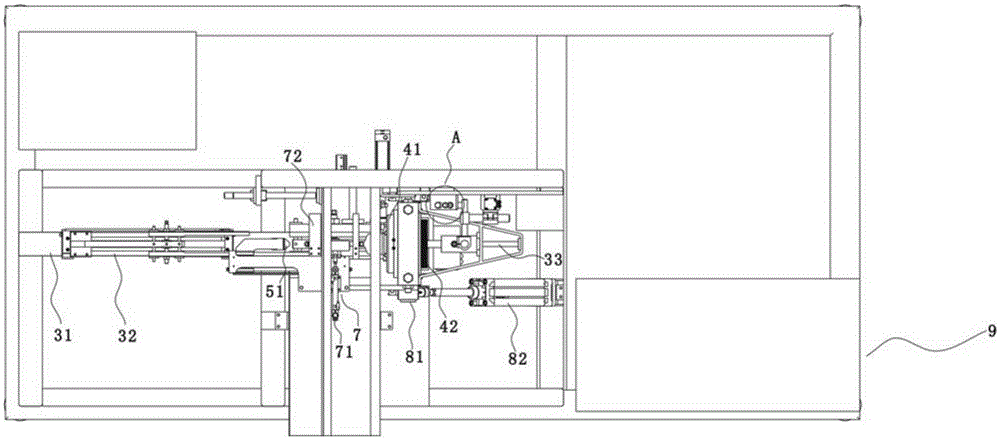

[0035] Such as Figure 1 to Figure 4 As shown, the special girth welding equipment provided in this embodiment using gas tungsten arc welding plus wire feeding is used for welding three-stage liquid reservoirs, such as Figure 11 shown. The special equipment for girth seam welding includes a frame 1, a feeding mechanism 2, a positioning and pushing mechanism 3, a mechanical power mechanism 4, a sealing and inflation mechanism 5, a welding mechanism 6 and a material unloading mechanism 7. The feeding mechanism 2 is arranged on the frame 1 , and the feeding mechanism 2 includes a material path 21 and an escapement assembly 22 arranged on the material path 21 . In this embodiment, the forehearth 21 is composed of two semicircular rails, and is fixed on the frame 1 by a fixed rod. The width of the forehearth 21 can be changed by adjusting the fixed position of the two rails on the fixed rod. , to apply to lap welded workpieces of different lengths, such as two-stage reservoirs o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com