Iron oxide pigment transportation device

A technology of iron oxide pigments and transportation devices, which is applied in the direction of transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of low transfer efficiency and potential safety hazards, and achieve the effects of facilitating continuous production, improving efficiency, and improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

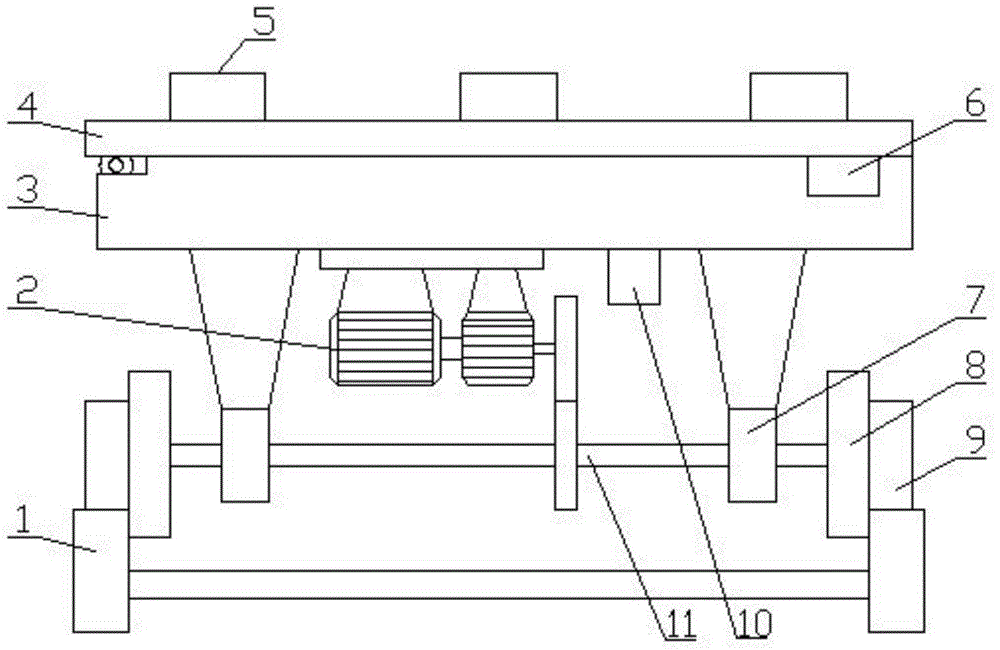

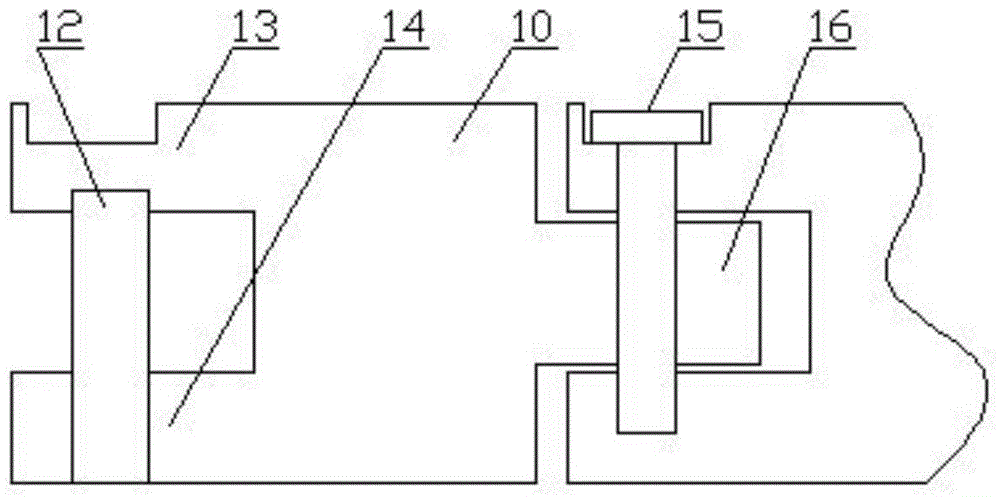

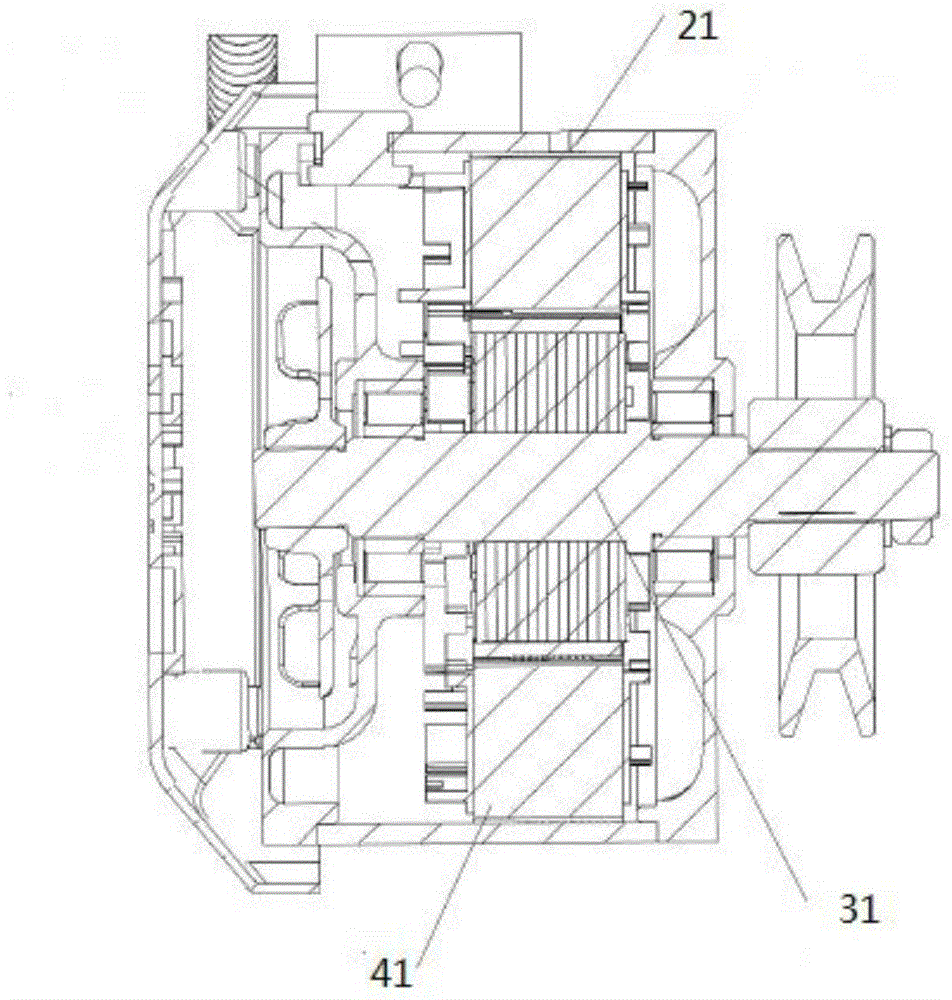

[0039] The iron oxide pigment transportation device of this embodiment includes an annular track arranged between the iron oxide pigment extruder and the iron oxide pigment tape winding device, one end of the annular track is close to the iron oxide pigment extruder, and the other end of the annular track is close to the iron oxide pigment extruder. One end is close to the iron oxide pigment tape winding device, the annular track is provided with at least two loading trolleys that can run on the annular track, the loading trolley includes a frame, the bottom of the frame is protruded with a bearing, the The bearing is provided with a rotating shaft, the two ends of the rotating shaft are provided with wheels, the inner side of the wheel is provided with a protruding anti-derailment flange, and the upper part of the frame is provided with a flat plate for loading and unloading iron oxide pigments; A connecting rod for controlling the spacing between adjacent loading trolleys is ...

Embodiment 2

[0041] The iron oxide pigment transportation device of this embodiment includes an annular track arranged between the iron oxide pigment extruder and the iron oxide pigment tape winding device, one end of the annular track is close to the iron oxide pigment extruder, and the other end of the annular track is close to the iron oxide pigment extruder. One end is close to the iron oxide pigment tape winding device, the annular track is provided with at least two loading trolleys that can run on the annular track, the loading trolley includes a frame, the bottom of the frame is protruded with a bearing, the The bearing is provided with a rotating shaft, the two ends of the rotating shaft are provided with wheels, the inner side of the wheel is provided with a protruding anti-derailment flange, and the upper part of the frame is provided with a flat plate for loading and unloading iron oxide pigments; A connecting rod for controlling the spacing between adjacent loading trolleys is ...

Embodiment 3

[0043] The iron oxide pigment transportation device of this embodiment includes an annular track arranged between the iron oxide pigment extruder and the iron oxide pigment tape winding device, one end of the annular track is close to the iron oxide pigment extruder, and the other end of the annular track is close to the iron oxide pigment extruder. One end is close to the iron oxide pigment tape winding device, the annular track is provided with at least two loading trolleys that can run on the annular track, the loading trolley includes a frame, the bottom of the frame is protruded with a bearing, the The bearing is provided with a rotating shaft, the two ends of the rotating shaft are provided with wheels, the inner side of the wheel is provided with a protruding anti-derailment flange, and the upper part of the frame is provided with a flat plate for loading and unloading iron oxide pigments; A connecting rod for controlling the spacing between adjacent loading trolleys is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com