Full-automatic rotary marking and gold blocking device

An indentation hot stamping machine, rotary technology, applied in the direction of object supply, pile separation, thin material processing, etc., can solve the problems of slow speed, high closing pressure, large safety hazards, etc., and achieve the effect of accurate position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

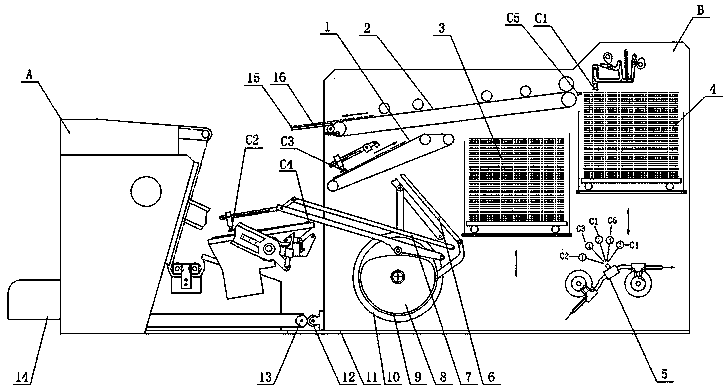

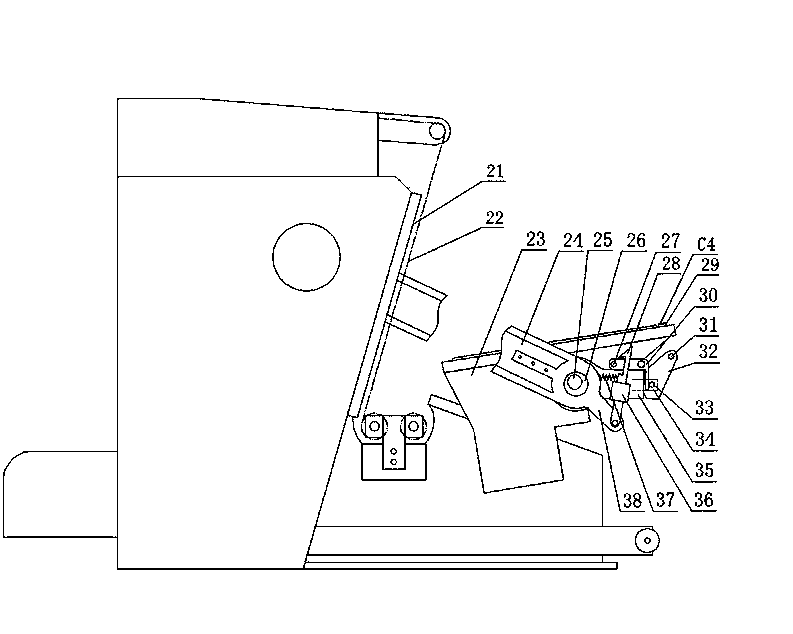

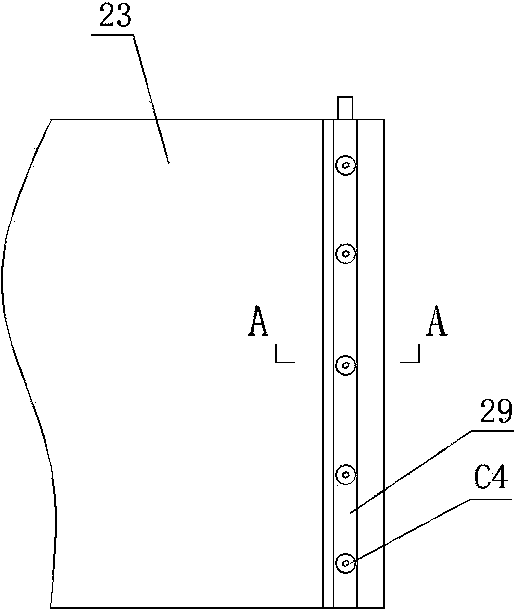

[0025] As shown in the figure, the fully automatic rotary creasing hot stamping equipment of the present invention includes a rotary creasing hot stamping machine A and an automatic paper feeding and receiving mechanism B, and the automatic paper feeding and receiving mechanism B includes a paper feeding lifting platform 4 and a paper receiving lifting platform 3. The paper feeding belt 2 and the paper receiving belt 1, the paper feeding belt 2 is set between the paper feeding lifting table 4 and the rotary creasing hot stamping machine A, and the paper feeding end of the paper feeding belt 2 is provided with the first suction nozzle assembly C1 The paper on the paper feeding elevator 4 is transferred to the paper feeding belt 2, and the fifth suction nozzle assembly C5 is also provided to face the side of the uppermost paper (working position) of the paper feeding elevator 4, and the paper output of the paper feeding belt 2 There is a second suction nozzle assembly C2 at the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com