Preparation method of cross-linked Na-CMC (sodium carboxymethylcellulose) with ultra-high viscosity

A technology of cross-linking carboxymethyl and sodium cellulose, which is applied in the field of preparation of sodium carboxymethyl cellulose, can solve the problem that the viscosity of sodium carboxymethyl cellulose cannot reach the industrial ultra-high viscosity, and the sodium carboxymethyl cellulose is substituted by sodium carboxymethyl cellulose. High viscosity, unfavorable product viscosity and other problems, to achieve the effect of increased viscosity, convenient operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

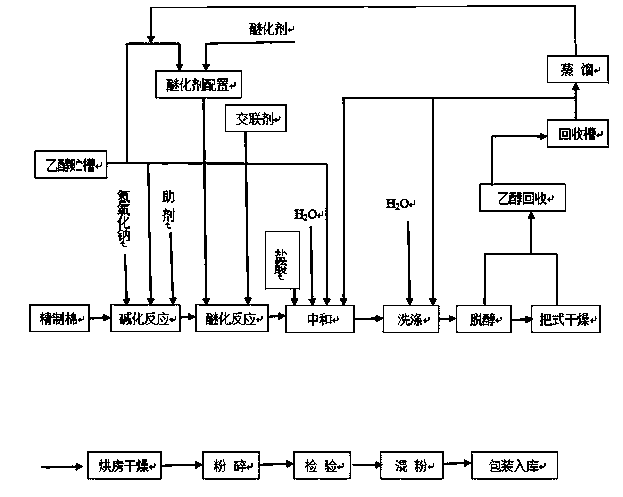

Image

Examples

Embodiment 1

[0024] Stir and mix 150.65kg of 48% sodium hydroxide aqueous solution and 140kg of 94.5% ethanol aqueous solution, and cool the mixture to 25°C for use; loosen 100kg of refined cotton into floc, put it into a 2000L kneader, and spray it into the kneader Drench the aforementioned sodium hydroxide / ethanol mixture, close the feeding port of the kneader to carry out the alkalization reaction, control the temperature of the alkalization reaction at 25°C, and react for 50 minutes; then, spray and drop 108.33kg of 75wt% ethanol chloroacetate into the kneader Liquid etherifying agent, while adding the etherifying agent dropwise, add the ethanol solution of 1,3-dichloropropanol to the kneader as a crosslinking agent, the total amount of 1,3-dichloropropanol added is 0.2kg, Pre-react at 30°C for 40 minutes; then raise the temperature of the reaction system to 75°C, and carry out etherification and heat preservation reaction for 50 minutes; after the reaction, cool the reaction product to...

Embodiment 2

[0027] Stir and mix 160.21kg of 40% sodium hydroxide aqueous solution and 132kg of 90% ethanol aqueous solution, and cool the mixture to 25°C for use; loosen 100kg of refined cotton into floc, put it into a 2000L kneader, and spray it into the kneader Drench the aforementioned sodium hydroxide / ethanol mixture, close the feeding port of the kneader to carry out the alkalization reaction, control the temperature of the alkalization reaction at 20°C, and react for 60 minutes; then, spray and drop 91.35kg of 75wt% ethanol chloroacetate into the kneader Liquid etherifying agent, while adding the etherifying agent dropwise, add the ethanol solution of 1,3-dichloropropanol to the kneader as a crosslinking agent, the total amount of 1,3-dichloropropanol added is 0.5kg, Pre-react at 40°C for 35 minutes; then raise the temperature of the reaction system to 80°C, and carry out etherification and heat preservation reaction for 60 minutes; after the reaction is completed, cool the reaction ...

Embodiment 3

[0030]Stir and mix 180.21kg of 45% sodium hydroxide aqueous solution and 160kg of 92% ethanol aqueous solution, cool the mixture to 25°C, and set aside; loosen 100kg of refined cotton into floc, put it into a 2000L kneader, and spray it into the kneader Drench the aforementioned sodium hydroxide / ethanol mixture, close the feeding port of the kneader to carry out the alkalization reaction, control the temperature of the alkalization reaction at 25°C, and react for 45min; then, spray and drop 105.75kg of 75wt% ethanol chloroacetate into the kneader Liquid etherifying agent, add the ethanol solution of 1,3-dichloropropanol to the kneader as a crosslinking agent while adding the etherifying agent dropwise, the total addition of 1,3-dichloropropanol is 0.8kg, Pre-react at 45°C for 40 minutes; then raise the temperature of the reaction system to 75°C, and carry out etherification and heat preservation for 80 minutes; after the reaction, cool the reaction product to below 50°C within ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com