Roller furnace

A rolling rod furnace and rolling rod technology, applied in furnaces, heat treatment furnaces, furnace types, etc., can solve the problems of increasing material brittleness, frequent thermal expansion and contraction, and lower product quality, so as to save energy, reduce loss, reduce volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

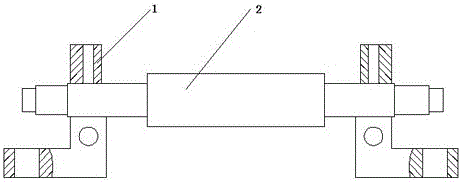

[0014] Such as figure 1 As shown, the rolling rod furnace of the present invention includes a rolling rod 2 and a rolling rod seat 1 . The rolling rod seat is fixed on the furnace body outside the heat preservation area on both sides of the working area of the rolling rod furnace. The rolling rod seat is provided with a rolling rod hole. The two ends of the rolling rod pass through the rolling rod hole of the rolling rod seat and are movably connected with the rolling rod seat. The gap between adjacent rolling rods in the working area of the rolling rod furnace is 3 mm, or any value between 4 mm or 3-4 mm.

[0015] The diameter of the rolling rod located in the working area of the rolling rod furnace is larger than that of the heat preservation section. The diameter of the heat preservation section is larger than the diameter of the section pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com