A special test sizing device for carbon fiber industrial production line

A production line and carbon fiber technology, which is applied in the processing of textile material dyeing devices, textiles and papermaking, and textile material processing, can solve the problems of unfavorable total cost of research and development, affecting the progress of new sizing agent development, and spending a lot of time and money. Conducive to the total cost of research and development, reduce the cost of research and development, the effect of low manufacturing and use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to deepen the understanding of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. The embodiments are only used to explain the present invention and do not limit the protection scope of the present invention.

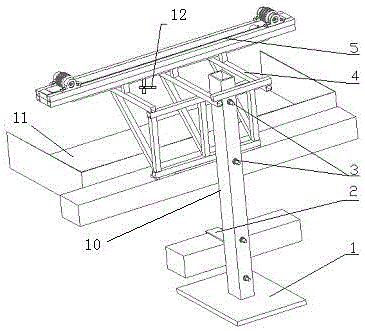

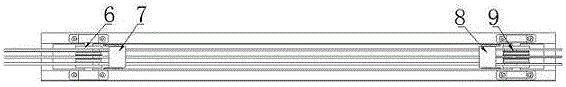

[0019] Such as Figure 1-2 As shown, the present invention is a special test sizing device for a carbon fiber industrial production line. The sizing device on the production line is a welded part structure. The sizing device includes a glue tank rack 4 fixed to the size tank 11 of the production line. The glue tank frame 4 and a column 10 are tightly fixed together by bolts 3, a dipping tank 5 is fixed on the glue tank frame 4, and the column 10 is fixed on the ground by bolts 3 and clamping sleeves 2. Above, a first dipping roller 7 and a second dipping roller 8 are respectively provided at both ends of the dipping tank 5, and left and right ends with a guide w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com