Texture anti-counterfeiting marker for highlighting ink foaming characteristic or ink wrinkle characteristic

An anti-counterfeiting marking and wrinkling technology, which is applied in fiber raw material processing, textile and papermaking, instruments, etc., can solve the problems of high cost and high customization cost of textured anti-counterfeiting special paper, and achieve the effect of easy operation and high accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

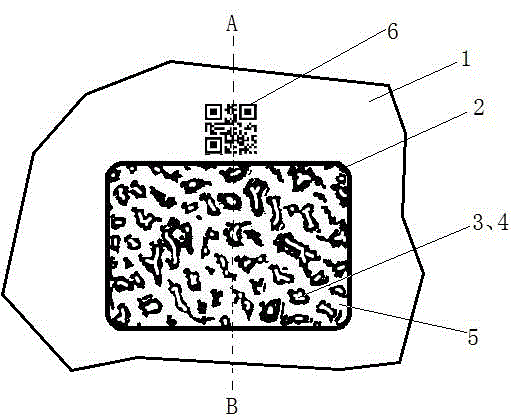

[0030] Such as figure 1 , figure 2 , image 3 As shown, choose 230g / m 2 white cardboard to produce anti-counterfeiting pill boxes.

[0031] Prepare some milky UV foaming ink.

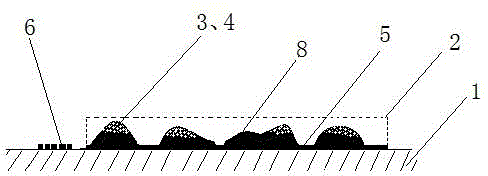

[0032] Use screen printing machine to 230g / m 2 Print a 26mm×16mm foam ink printing layer (2) on white cardboard, and then irradiate it with a UV curing lamp to cure and foam.

[0033]Make another 24mm×14mm flexo printing plate (slightly smaller than the foaming ink printing layer), and print on the foaming ink printing layer (2) with red flexo printing ink, so as to print and dye the peak of the bubble (3) in red , that is, printing a colored ink layer (4) with a color different from that of the foaming ink on the peak (3) of the bubble, and drying it. figure 2 The dwarf peak (8) in , due to its shortness, cannot be touched by the printing plate, so it is not stained red.

[0034] Since each bubble is formed by random foaming, manpower cannot control its shape, size and height. Their peak (3) ...

Embodiment 2

[0040] Such as figure 1 , figure 2 , image 3 As shown, choose 230g / m 2 white cardboard to produce anti-counterfeiting pill boxes.

[0041] Get some milky UV wrinkle ink ready.

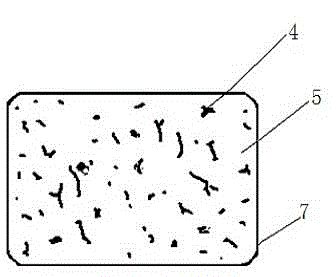

[0042] Use screen printing machine to 230g / m 2 A 26mm×16mm wrinkle ink printing layer (2) was printed on white cardboard, and then irradiated with a UV curing lamp to cure and wrinkle.

[0043] Make another 24mm×14mm flexo printing plate (slightly smaller than the wrinkle ink printing layer), and print on the wrinkle ink printing layer (2) with red ink, so as to dye the peak of the wrinkle (3) red, that is, at the wrinkle A colored ink layer (4) with a color different from that of the wrinkle ink is printed on the peak (3) and dried.

[0044] Compile and print an identification code such as a link URL QR code containing a query URL and a serial number for each medicine box (6).

[0045] Then use an industrial-grade digital camera to take pictures of the identification code (6) and the red peak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com