Method for estimating charge air cooler condensation storage and/or release

A charge air cooling and charge air technology, applied in the control of coolant flow, combustion air/combustion-air treatment, machine/engine, etc., can solve the problem of not accurately reflecting the amount of water, unstable combustion, and engine misfire And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

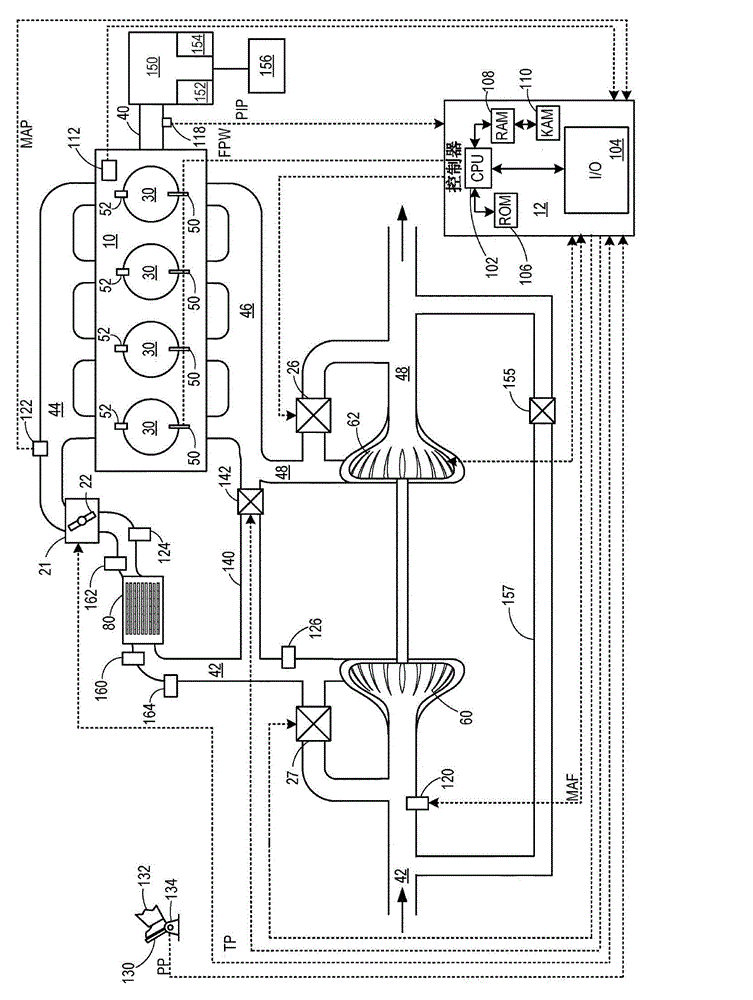

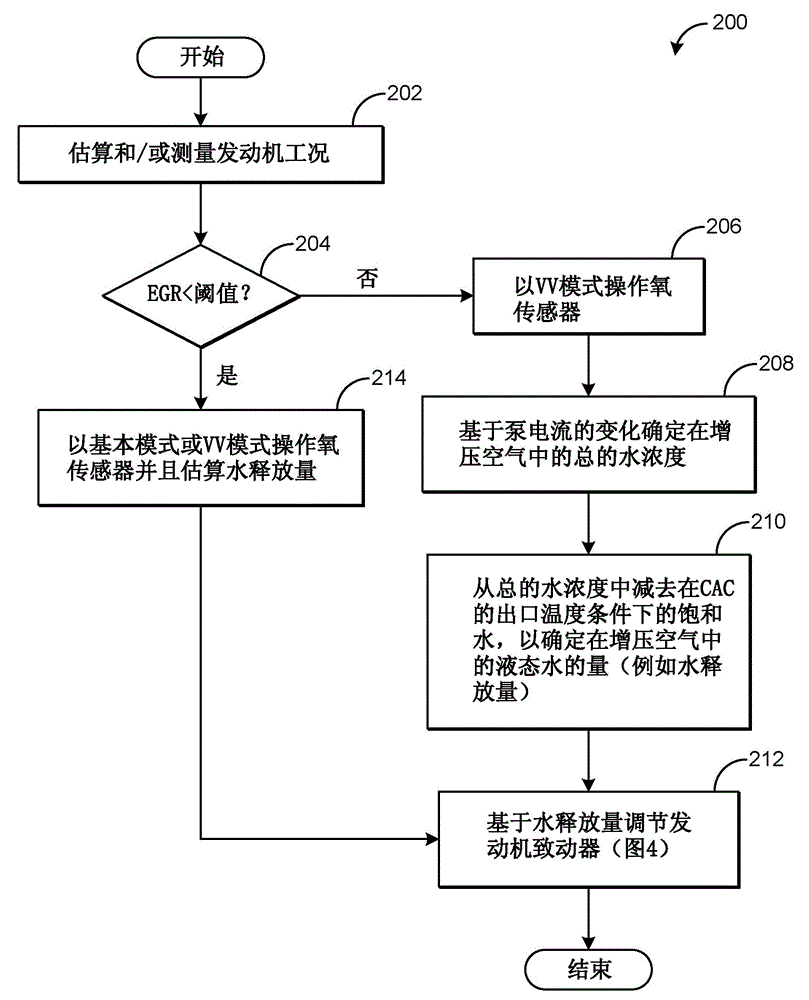

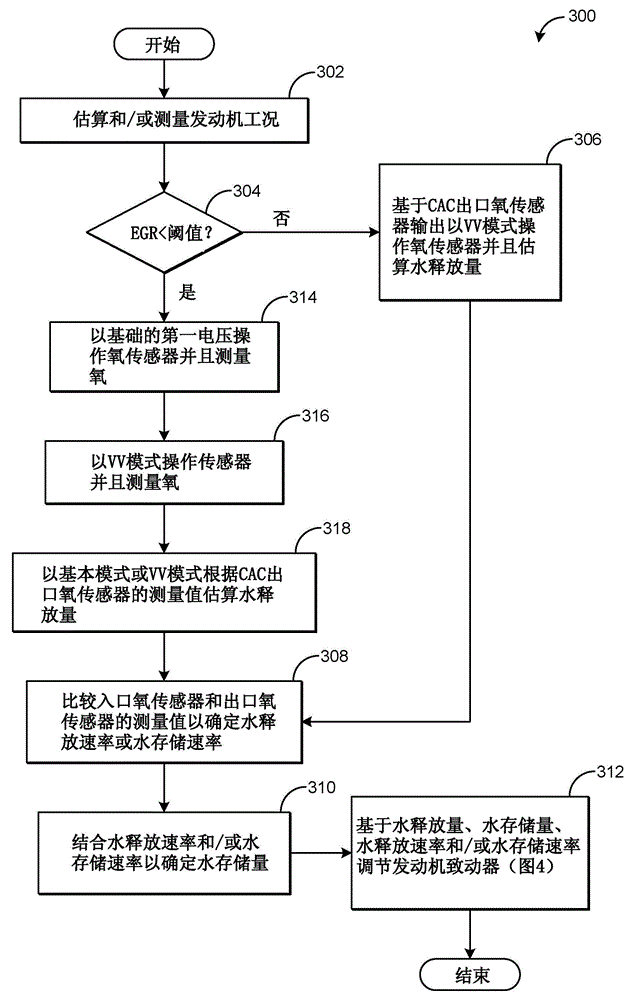

[0012] The following description relates to systems and methods for estimating water storage in a charge air cooler (CAC) in an engine system, such as figure 1 system. A first oxygen sensor may be located at the outlet of the CAC. In one example, the oxygen sensor may be a variable voltage port oxygen sensor, which may operate in a variable voltage (VV) mode or a fundamental mode. figure 2 A method for operating a first oxygen sensor to determine water storage in a CAC is shown. Specifically, the amount of water released or in the charge air at the outlet of the CAC may be determined with the first oxygen sensor. In some examples, a second oxygen sensor may be positioned at the inlet of the CAC. image 3 A method for operating a first oxygen sensor and a second oxygen sensor to determine a water storage parameter at a CAC is shown. Water storage parameters may include a rate of water storage, a rate of water release, an amount of water storage (eg, the amount of water or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com