Improved brick structure for grate cooler parapet

A grate cooler and brick laying technology, which is applied in the field of brick laying, can solve the problems of inability to guarantee maintenance and baking, difficulty in dismantling, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

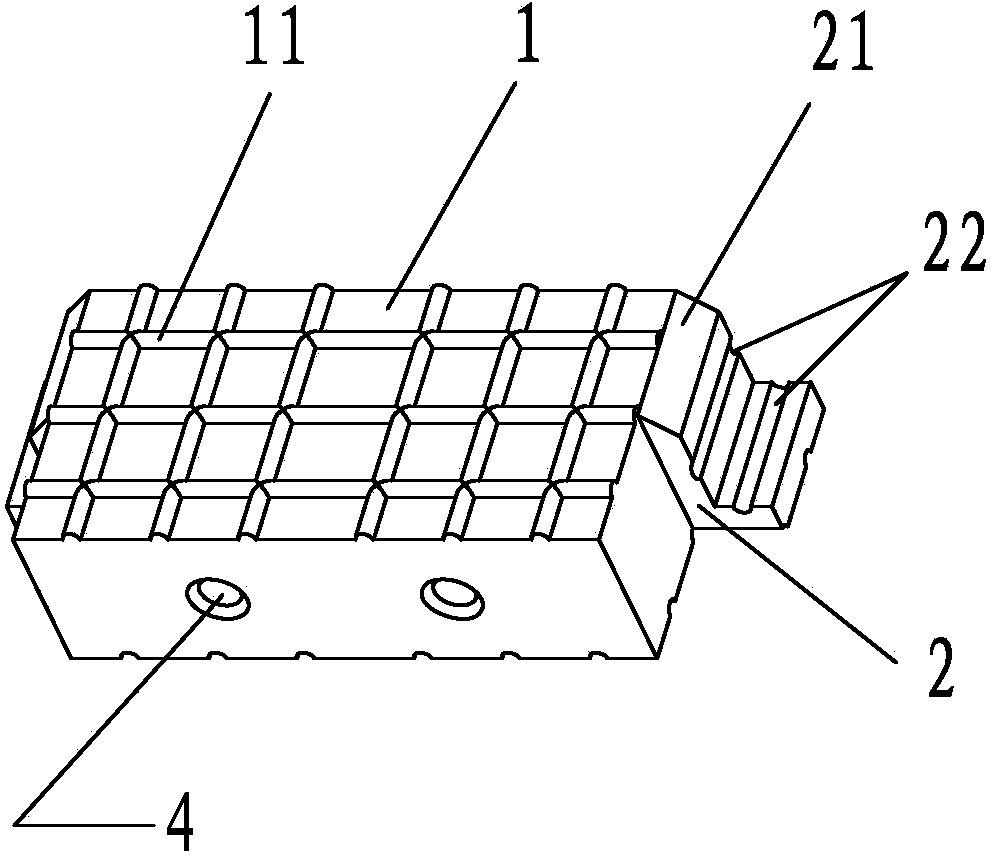

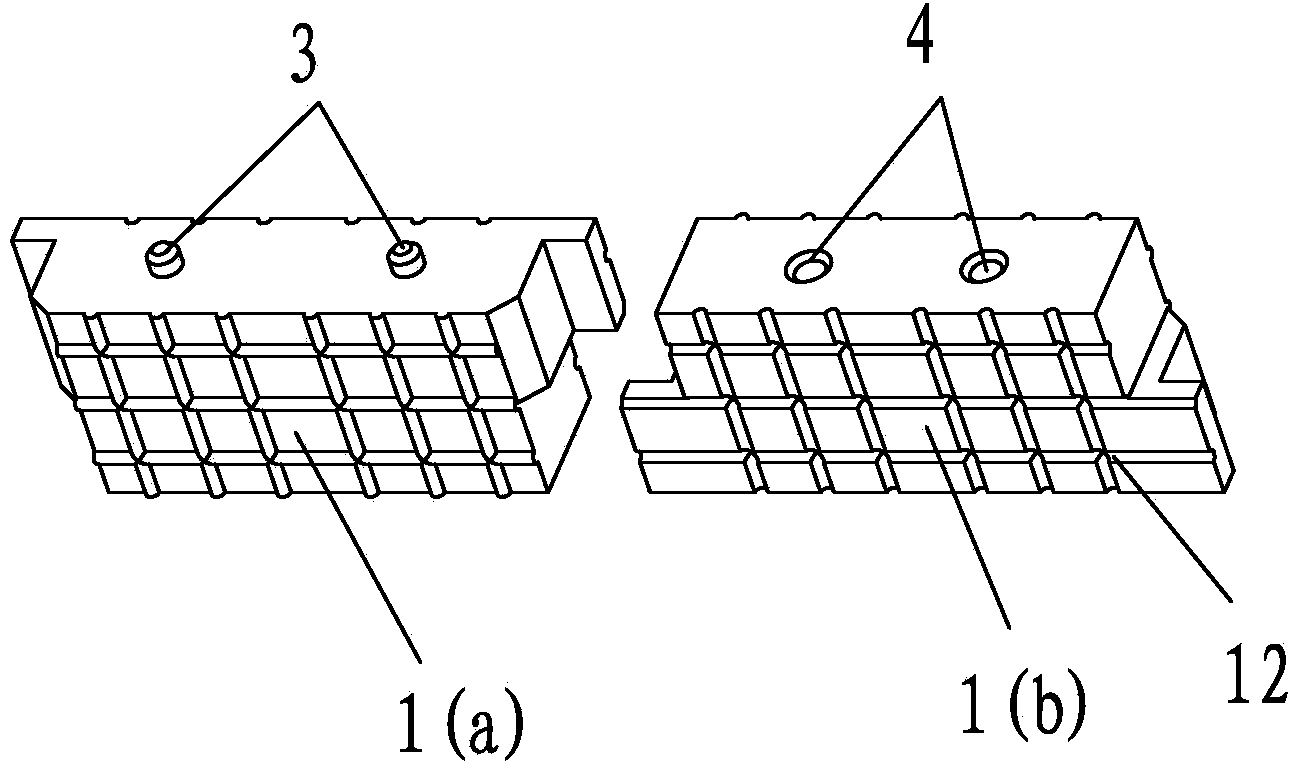

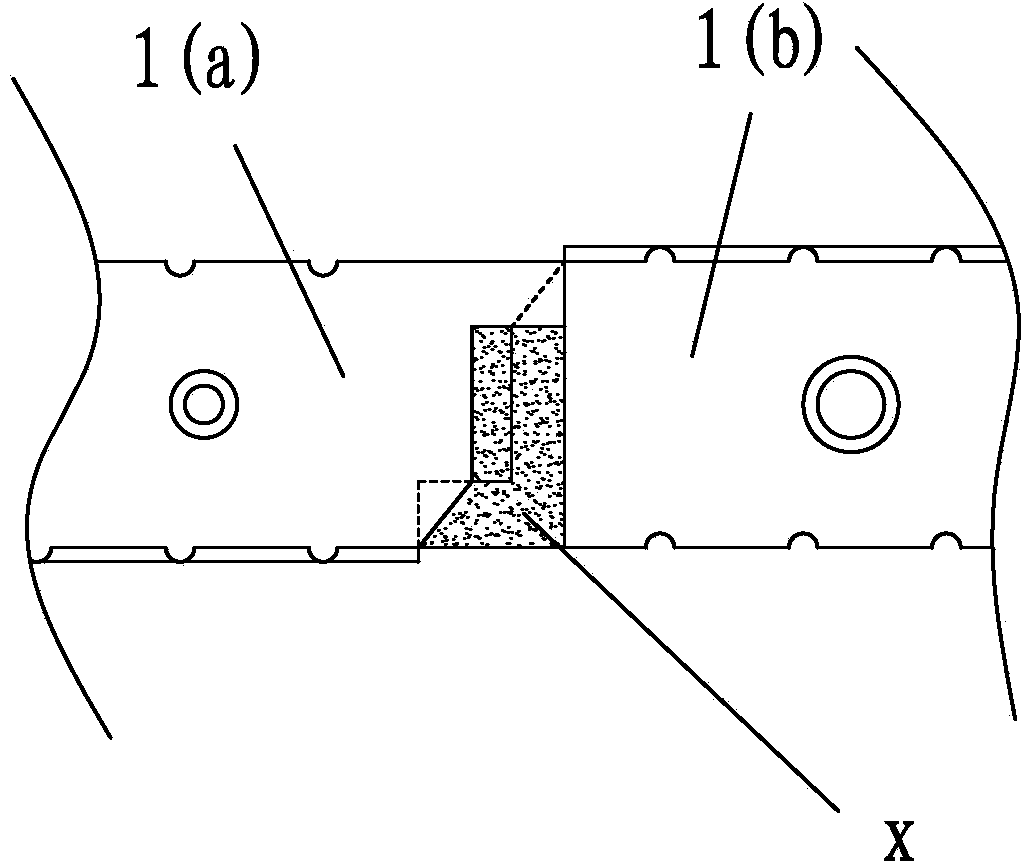

[0016] Such as Figure 1 to Figure 2 As shown, an improved brick-laying structure for the low wall of the grate cooler includes a brick-laying body 1, and side wings 2 are arranged on both sides of the brick-laying body. The height of the side wings is half of the height of the brick-laying body, and the side wings The top surface of the side panel is aligned with the top surface of the brickwork body, and the section of the wing plate is L-shaped, such as figure 2 As shown, when the two brick bodies a and b on the left and right are connected, the brick b is turned upside down with the back facing outwards, at this time the side panels of the two bricks are naturally staggered, and the side panels of the brick a are located at figure 2 Above the back of the , the side panels of the brickwork b are located figure 2 Below the front of the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com