Thickness detecting probe for wheel type pipeline detector

A detector and thickness measurement technology, applied in pipeline systems, instruments, measuring devices, etc., can solve the problems of soft material of thickness measurement wheel, small diameter range of pipelines, high cost, and achieve strong impact resistance and wear resistance, detection Accurate signal and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

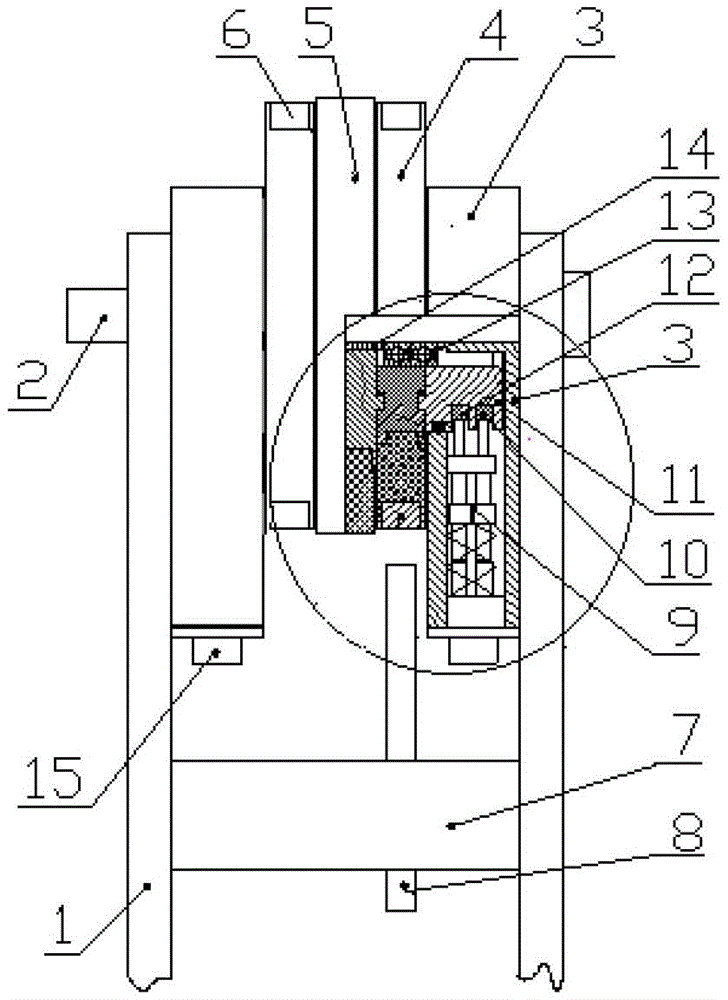

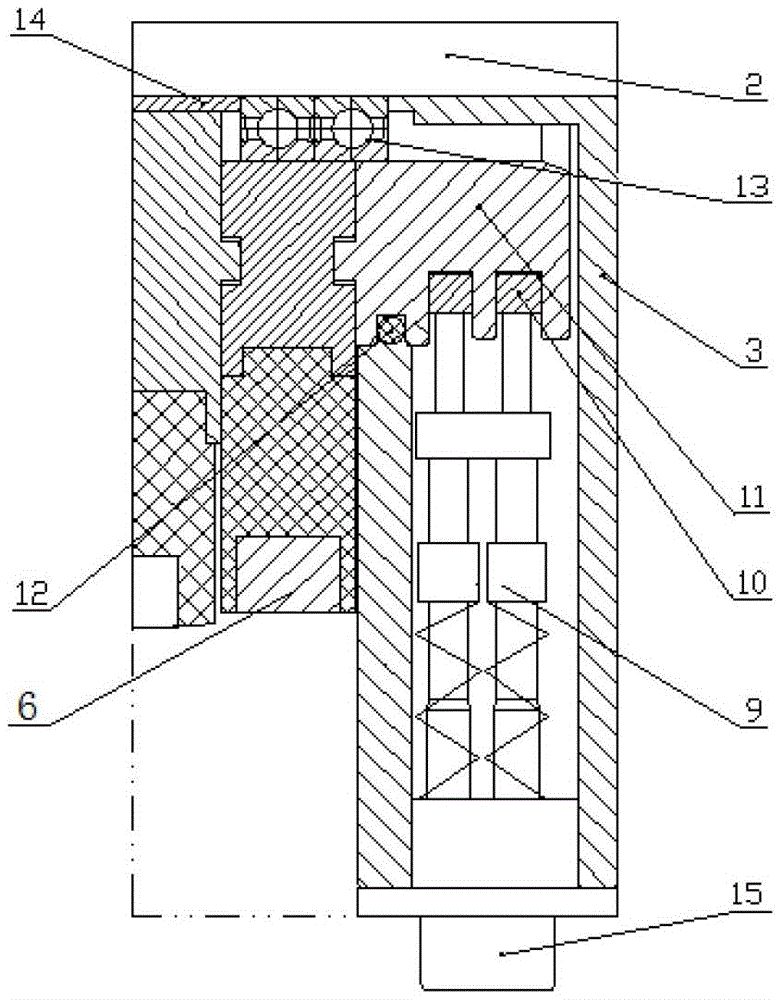

[0016] refer to Figures 1 to 9 Embodiments of the present invention are further described:

[0017] The thickness measuring probe includes support arm 1, shaft 2, end cover 3, support wheel 4, thickness measuring wheel 5, metal block 6, fixed seat 7, proximity switch 8, carbon brush device 9, slip ring 10, slip ring seat 11 , sealing ring 12, bearing 13, spacer sleeve 14 and screw 15:

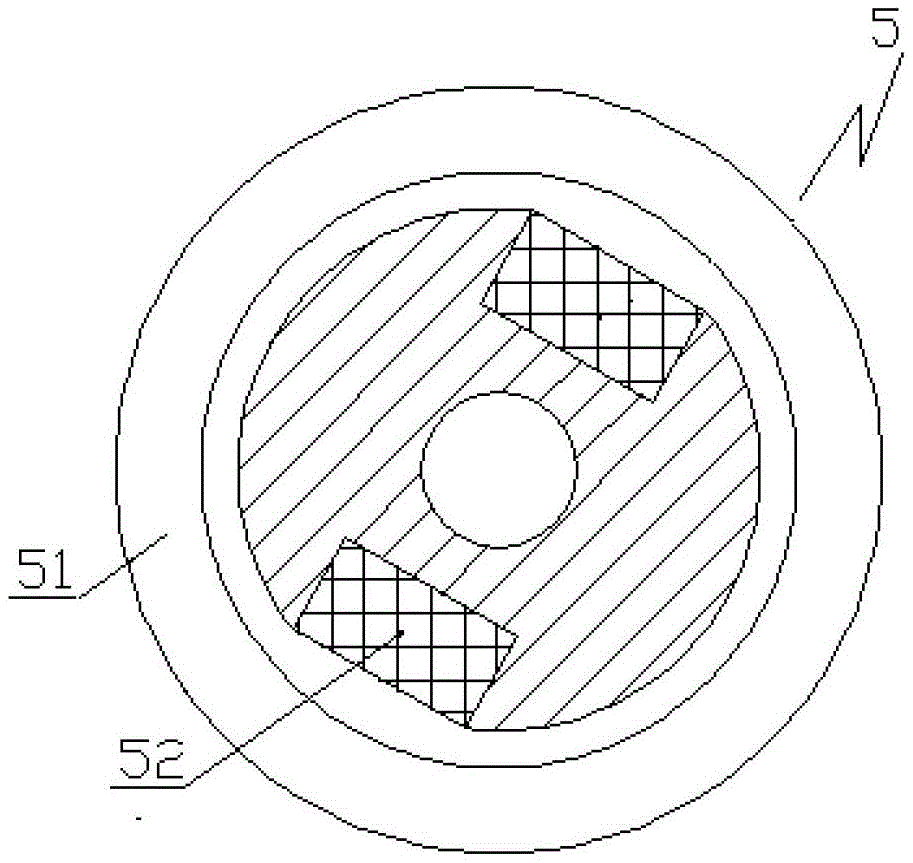

[0018] The fixed seat 7 for fixing the proximity switch 8 is connected between two parallel, length-adjustable support arms 1, and the shaft 2 is connected between the ends of the two support arms 1. The thickness measuring wheel 5 is set on the shaft 2 through the spacer sleeve 14 in its center hole, and ultrasonic probes 52 are arranged in the symmetrical grooves on the peripheral surface of the hub, and symmetrical convex keys are respectively arranged on the two ends of the hub, and the outer surface of the hub is The edge is the elastic casting body 51 of the thickness measuring wheel. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com