Maximum cracking degree determination method of coking raw material

A technology of coking raw materials and determination method, which is applied in the field of delayed coking for heating heavy oil, can solve the problems of hindering the superposition of free radicals, acceleration, slow formation of coking precursors, etc., and achieves the effect of convenient cracking degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

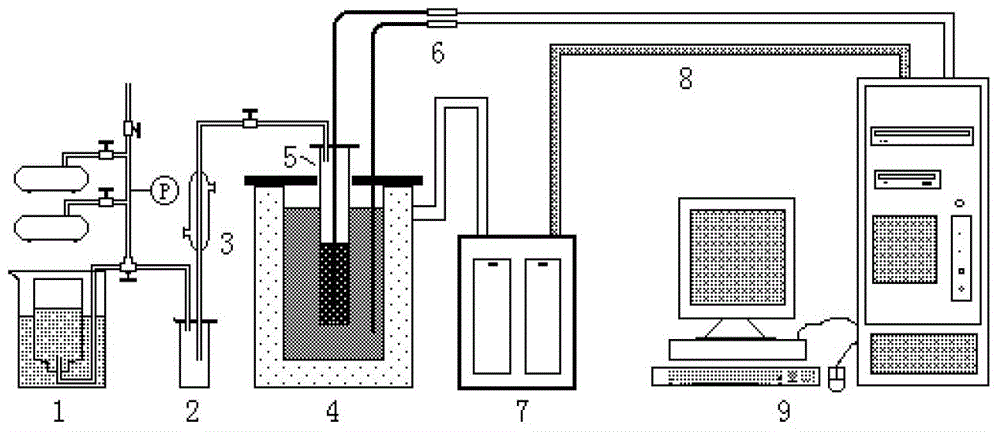

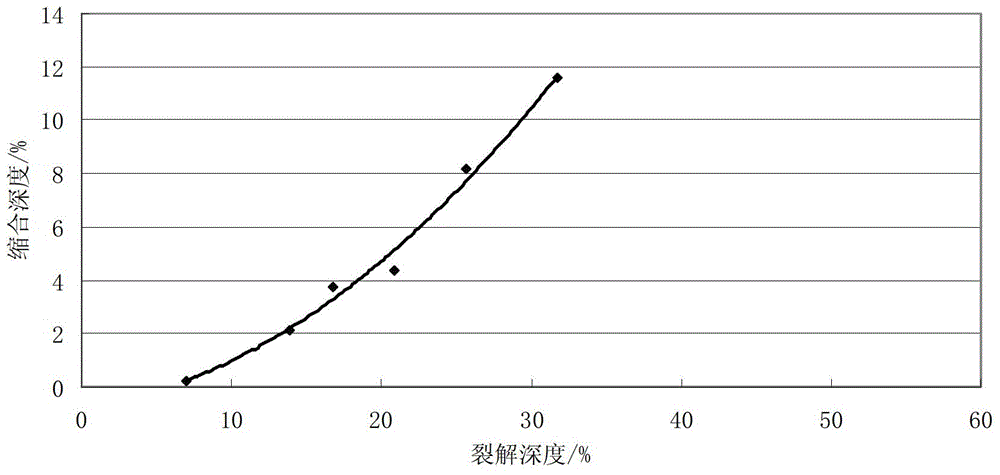

[0029] First take 8g oil sample 1, adopt figure 1 The device is used for thermal reaction experiments. The reaction temperature is controlled at 430°C and the reaction time is 16 minutes. Gas, liquid, and residual oil samples are collected and weighed; The sum of fraction increment and gas yield represents the depth of cracking; another part of the residual oil after the reaction is washed with toluene and then centrifuged to obtain the yield of toluene insolubles, which represents the depth of condensation; different reaction conditions are controlled (410°C / 6min , 410°C / 10min, 410°C / 15min, 410°C / 20min, 410°C / 30min), repeat the above experiment to obtain the cracking-condensation curve of the oil sample, and obtain the maximum crackability of oil sample 1 as 7%.

Embodiment 2

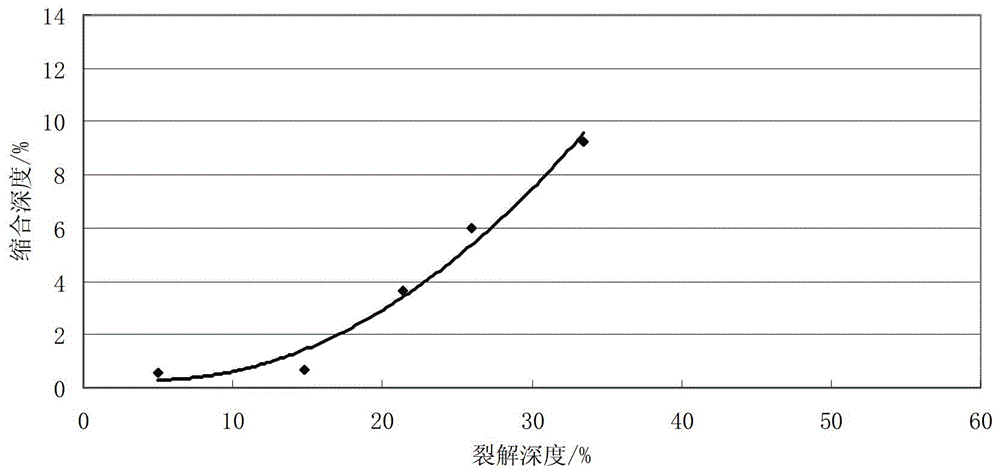

[0031] First take 9g oil sample 2, adopt figure 1 The device is used for thermal reaction experiments, the reaction temperature is controlled at 410°C and the reaction time is 20 minutes, gas, liquid and residual oil samples are collected and weighed; then a part of the residual oil and raw oil after the reaction is subjected to chromatographic simulated distillation, and the reaction temperature is 540°C before and after the reaction. The sum of fraction increment and gas yield represents the depth of cracking; another part of the residual oil after the reaction is washed with toluene and then centrifuged to obtain the yield of toluene insolubles, which represents the depth of condensation; different reaction conditions are controlled (410°C / 30min , 430°C / 10min, 430°C / 16min, 430°C / 30min), repeat the above experiment to obtain the cracking-condensation curve of the oil sample, and obtain the maximum crackability of oil sample 2 as 9%.

Embodiment 3

[0033] First take 8.5g oil sample 3, adopt figure 1 The device is used for thermal reaction experiments. The reaction temperature is controlled at 430°C and the reaction time is 16 minutes. Gas, liquid, and residual oil samples are collected and weighed; The sum of fraction increment and gas yield represents the depth of cracking; another part of the residual oil after the reaction is washed with toluene and then centrifuged to obtain the yield of toluene insolubles, which represents the depth of condensation; different reaction conditions are controlled (410°C / 10min , 410°C / 15min, 410°C / 20min, 410°C / 30min), repeat the above experiment to obtain the cracking-condensation curve of the oil sample, and obtain the maximum crackability of oil sample 3 of 20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com