High seal strength flexible liquid crystal box and manufacturing method thereof

A technology of flexible liquid crystals and manufacturing methods, which is applied in nonlinear optics, instruments, optics, etc., and can solve problems such as easy cracking of the frame glue and poor sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

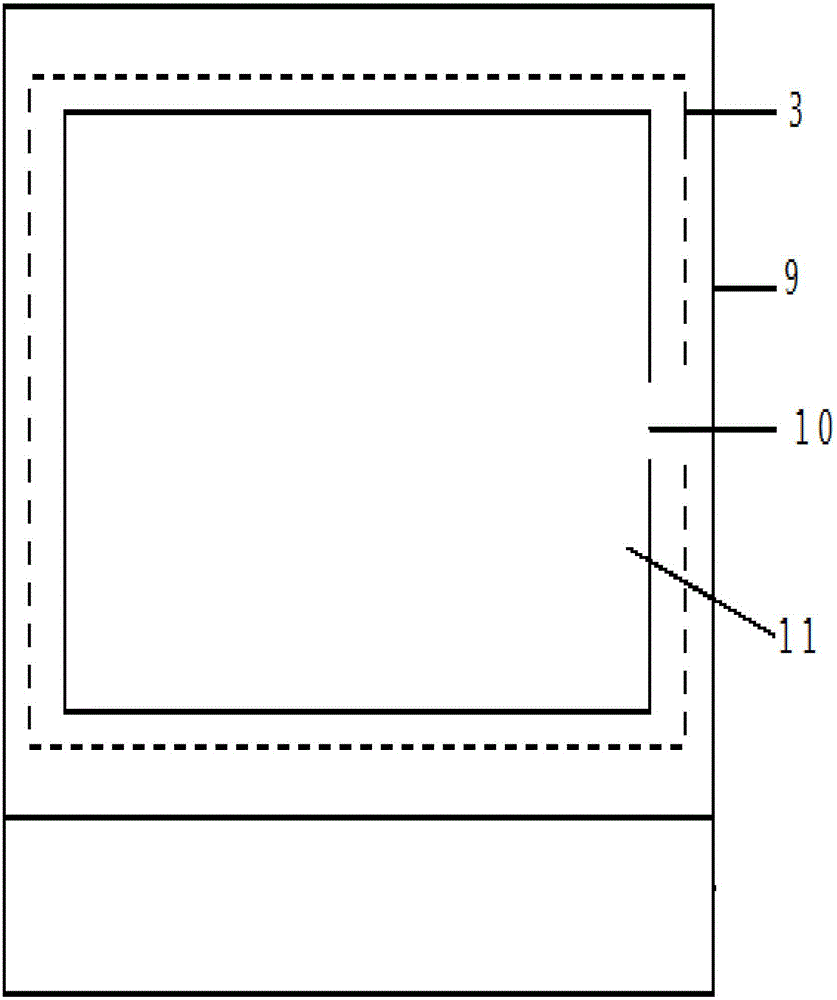

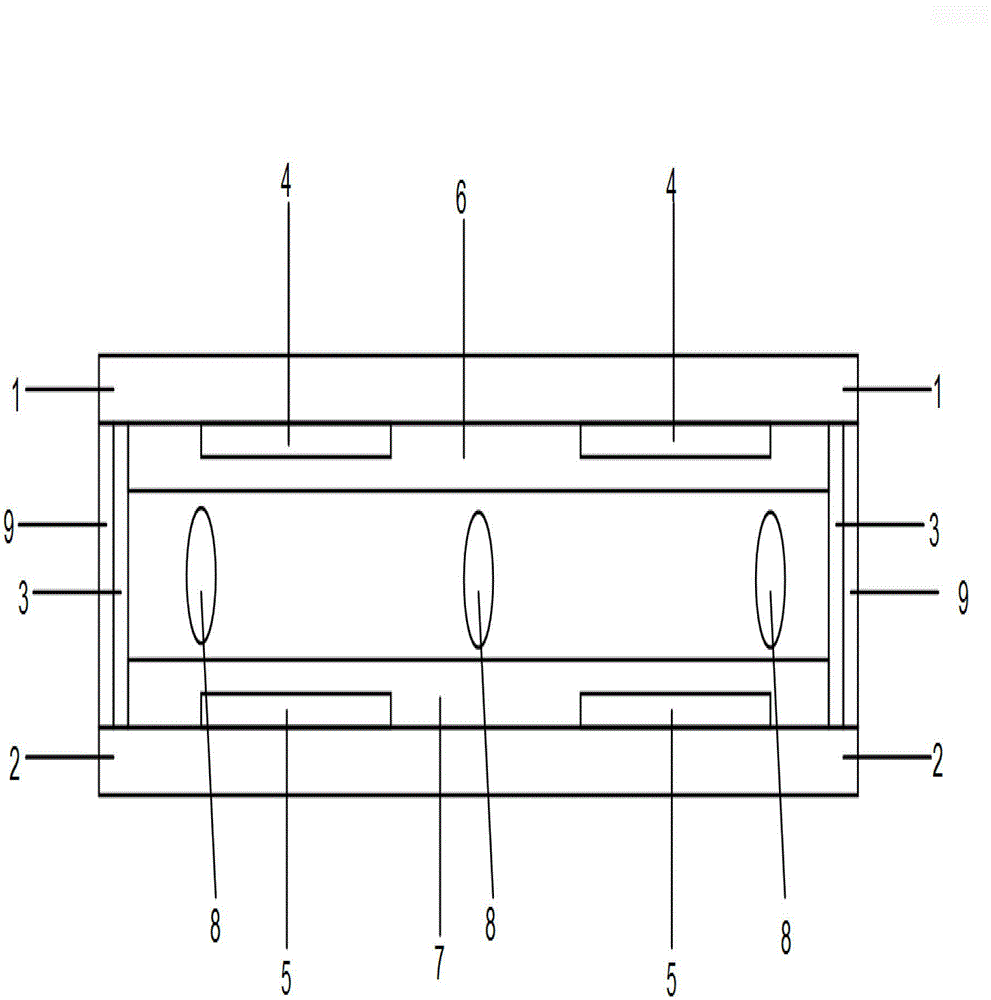

[0270] A flexible liquid crystal cell with high sealing strength, comprising an upper flexible substrate, a lower flexible substrate, adhesive glue, an upper electrode, a lower electrode, an upper alignment film, a lower alignment film and a liquid crystal. The upper flexible substrate and the lower flexible substrate are both adopted Flexible plastic film.

[0271] Example 2:

[0272] A flexible liquid crystal cell with high sealing strength, which is similar to Embodiment 1, except that the upper flexible substrate and the lower flexible substrate adopt an upper flexible ITO plastic film 1 and a lower flexible ITO plastic film 2 respectively.

Embodiment 3

[0274] A flexible liquid crystal cell with high sealing strength, which is similar to Embodiment 2, except that the upper flexible ITO plastic film 1 is arranged in parallel at a relative position above the lower flexible ITO plastic film 2.

Embodiment 4

[0276] A flexible liquid crystal cell with high sealing strength, similar to Example 3, except that the upper flexible ITO plastic film 1 and the lower flexible ITO plastic film 2 both use PET (polyethylene terephthalate) Made of conductive film. The upper flexible ITO plastic film 1 and the lower flexible ITO plastic film 2 can be bent, but are not easily broken.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com