A Computational Method for Gas Slip Flow in Microfluidic Devices with Complicated Geometric Boundaries

A technology of microfluidic devices and computing methods, which is applied in computing, instruments, and special data processing applications, etc., can solve the problems of less research, and achieve the effect of convenient use and strong adaptability to geometric boundaries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0042] Example 1: Using the proposed calculation method, the pressure-driven slip flow in a circular microchannel is calculated. The geometric boundary of the circular microchannel is not a plane but an arc surface, and due to the regular geometric shape, an analytical solution exists. Therefore, the correctness of this method can be verified through this example. The flow characteristics in the microchannel can be expressed by the Poiseuille number (Po):

[0043]

[0044] In the formula, F is the friction factor, Re is the Reynolds number, is the average pressure gradient in the flow direction, D h is the hydraulic diameter, is the average velocity at the cross section. For the macroscopic circular pipe flow, without considering the rarefaction effect, Po=64. For circular microchannels, Po and Kn numbers satisfy the following relationship:

[0045]

[0046] Take (2-σ t ) / σ t =1.6, under different Kn numbers, the analytical and numerical solutions obtained are ...

example 2

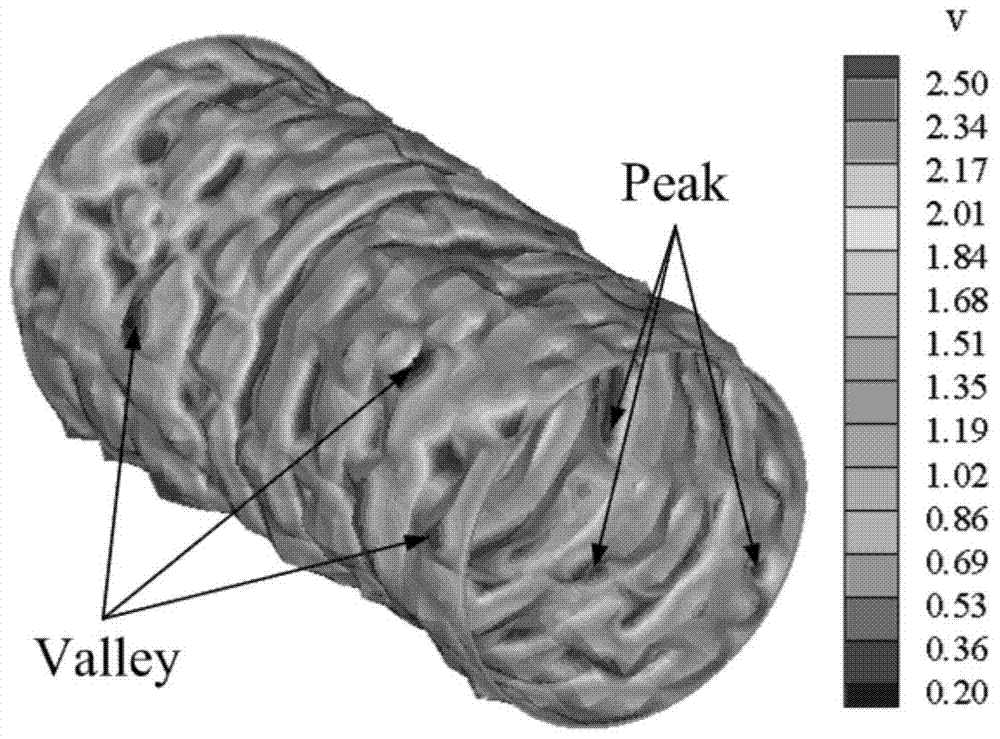

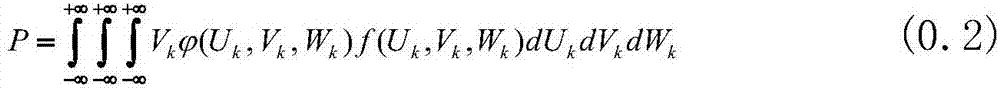

[0050] Example 2: Calculation of the effect of random surface roughness on slip flow in a circular microchannel. The geometric boundaries of random rough circular microchannels are complex, and the conventional sliding boundary conditions are difficult to deal with, but using this method, better results can be obtained. figure 1 Given the slip velocity at the surface of the random rough microchannel, it can be found that the slip velocity is small at the position with relatively large roughness (trough); while at the position with relatively small roughness (peak), the slip velocity Great speed. Similar results were obtained when researchers used different methods to study the effect of roughness profiles on 2D slip flow. However, this method can accurately capture the gas slip characteristics of the three-dimensional random rough surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com