Aluminum conductor for automotive wiring

An aluminum wire and wiring technology, applied in conductors, insulated conductors, metal/alloy conductors, etc., can solve problems such as increasing the space occupied by wires, thickening cables, and difficulty in laying and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

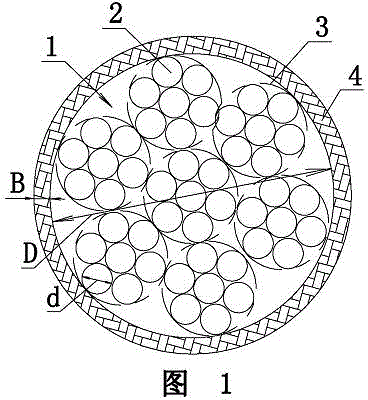

[0022] Such as figure 1 As shown, the cable core 1 is formed by twisting 19 aluminum monofilaments 2 (each black dot in the figure represents an aluminum monofilament), and the aluminum monofilament 2 is made of aluminum alloy. The outer periphery of the cable core 1 is covered with an insulating layer 4, and the cross-sectional outer diameter of each aluminum monofilament 2 is d=0.30mm. Considering the error of monofilament extrusion, the sum of the cross-sectional areas of 19 aluminum monofilaments 2 is ΣS 1 Controlled between 1.25m㎡—1.15m㎡, so the wire is nominally ∑S 1 It is 1.25 m㎡, and the aluminum wire of this structure is used in automobile signal control lines. The outer diameter of the insulating layer 4 is controlled between 1.70mm-1.90mm, and the inner diameter of the insulating layer 4 is controlled between 1.46mm-1.66mm. This structure is also correspondingly suitable for the outer diameter d=0.15mm-0.45mm of the section of the aluminum monofilament 2, and the ...

Embodiment 2

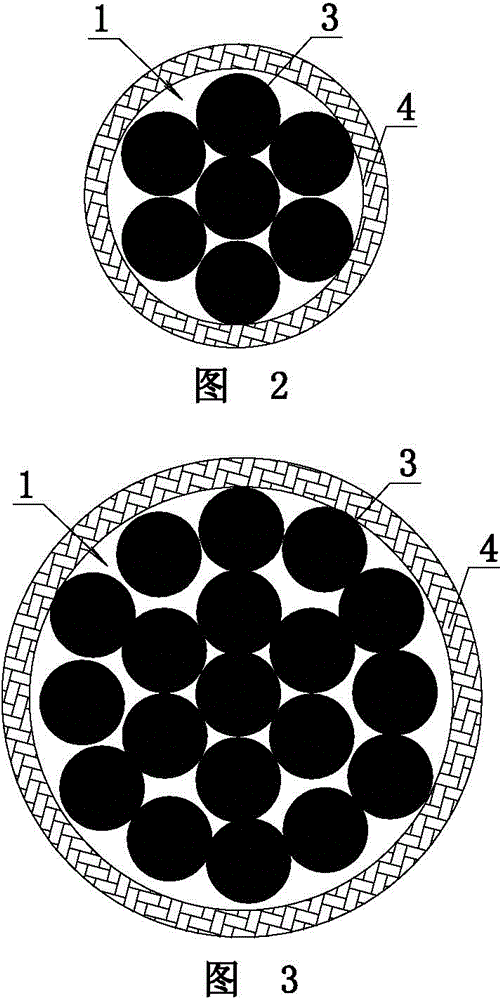

[0024] Such as figure 2 As shown, the cable core 1 includes 59 aluminum monofilaments 2 (each black dot in the figure represents a strand), the aluminum monofilaments 2 are made of pure aluminum or aluminum alloy, and each aluminum monofilament The outer diameter d=0.42mm. The cable core 1 adopts a two-layer complex twisted structure. The cable core 1 is twisted and arranged from the inside to the outside with a core strand and an outer strand. The core strand is made of 11 aluminum monofilaments twisted, and the outer strand The lines are all twisted from 8 aluminum monofilaments. The stranding direction of the core strands is leftward (S direction), and the stranding pitch is 45mm; the stranding direction of the outer strands is leftward (S direction), and the stranding pitch is 38mm; There are 6 outer strands twisted on the outer periphery of the core strands through complex twisting. The complex twisting direction of the outer strands is right (Z direction), and the com...

Embodiment 3

[0026] Such as image 3 As shown in the aluminum wire for automotive wiring, the cable core 1 includes 1520 aluminum monofilaments 2 (each black dot in the figure represents a strand of wire), the aluminum monofilament 2 is made of pure aluminum, each aluminum The outer diameter d=0.72mm of the quality monofilament 2, the sum of the cross-sectional areas of 1520 aluminum monofilaments 2 ∑S 1 It is controlled between 122 m㎡—113 m㎡, so the wire is nominally ∑S 1 The outer diameter of the insulating layer 4 is 17.70mm-19.70mm, and the inner diameter of the insulating layer 4 is controlled between 16.40mm-18.50mm. The cable core 1 adopts a three-layer complex twisted structure, and the cable core 1 is twisted and arranged in sequence from the inside to the outside, including core strands, middle strands and outer strands, and each strand includes 80 aluminum monofilaments, forming 1×80+6×80+12×80 cable structure. The core strand is located at the center of the cable core 1. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com