Straight-line multipath fuse box

An in-line fuse box technology, applied in circuits, emergency protection devices, electrical components, etc., can solve the problems of large size, limited number of fuses connected to PCB board type fuse boxes, inconvenient installation and maintenance, etc., to achieve small size, Ease of diagnosis and maintenance, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

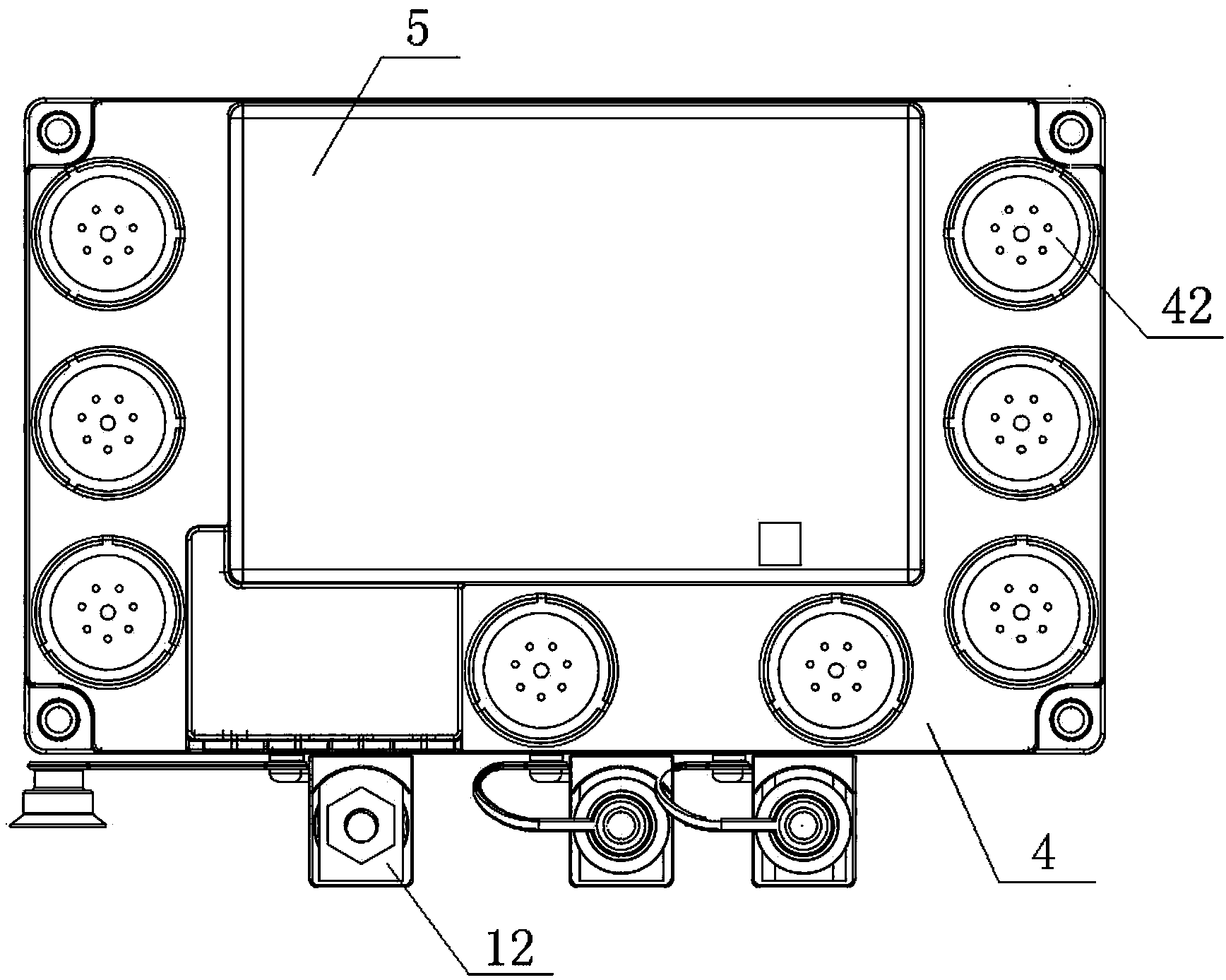

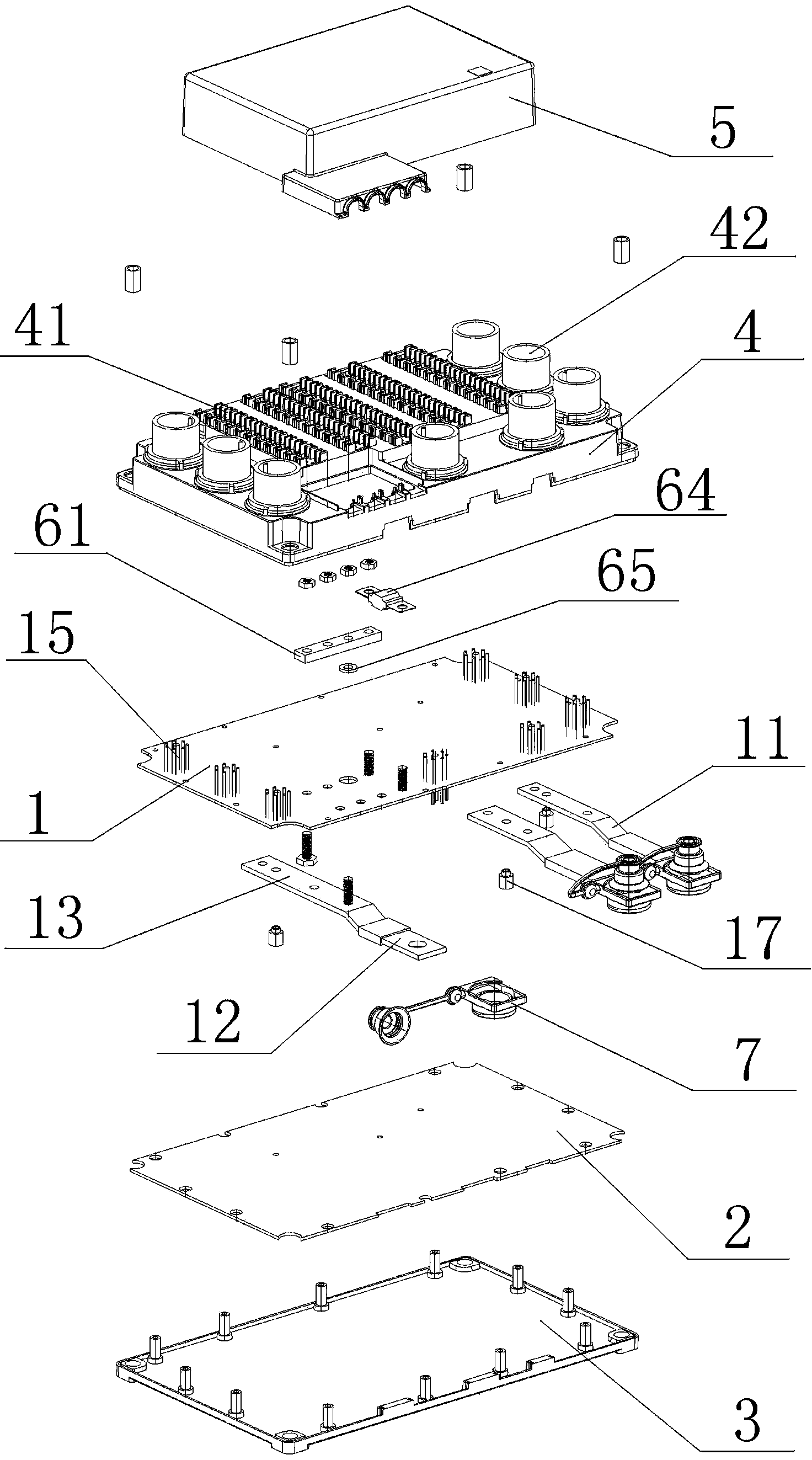

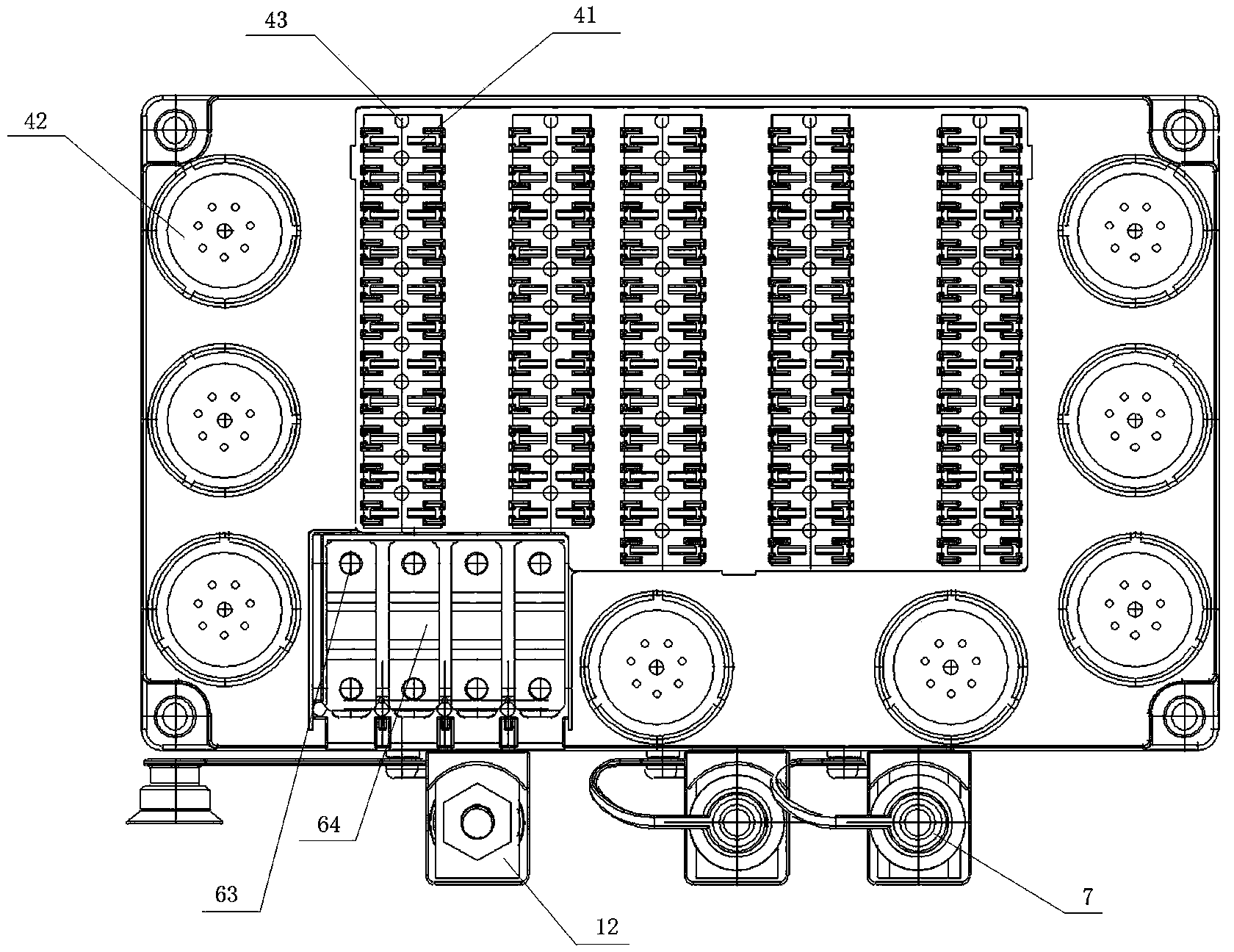

[0035] Embodiment 1: An in-line multi-way fuse box, including a box body and a PCB circuit board installed in the box body, the PCB circuit board includes an upper board 1 and a lower board 2, and three fuses are arranged on the back of the upper board 1 Parallel input copper bars, input copper bars 11 include power supply terminals 12 extending beyond the edge of the upper board, and circuit connection sections 13 fastened to the back of the upper board by conductive bolts, on the front of the upper board 1, the input copper bars A row of insurance slots 14 are respectively provided on both sides of the circuit connection section 13 of the circuit, and the vertical distance from each insurance slot to the input copper bar 11 is equal. The circuit connecting section 13 of the copper bar 11 is electrically connected; the front of the upper board 1 is also provided with a wiring harness access terminal 15; the lower board 2 is installed on the back of the upper board 1, and betwe...

Embodiment 2

[0039] Embodiment 2: a kind of in-line multi-way fuse box, such as Figure 1 to Figure 5 As shown, the difference from Embodiment 1 is that it also includes a group of high-current safety devices. The high-current safety device includes a dedicated copper bar 61, fastening bolts 62, and 4 safety lead-out bolts. The special copper bar 61 It is arranged on the front of the upper board 1 and forms a cross intersection with one of the input copper bars. A bolt access hole is opened at the cross position of the upper board 1, and a cylindrical copper ring 65 is arranged in the bolt access hole. The copper ring The thickness of 65 is greater than the thickness of the upper plate 1, and the fastening bolts 62 pass through the lower input copper bar 11, the middle copper ring 65 and the upper dedicated copper bar 61 in order to fasten them together to form an electrical connection; Bolts 63 pass through the upper plate 1 and the dedicated copper bar 61 to form a bolt-fixed insurance a...

Embodiment 3

[0040] Embodiment 3: An in-line multi-way fuse box, which differs from Embodiment 2 in that there are four input copper bars and 90 fuse slots.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com