Image sensor and fabricating method of image sensor

一种影像感测器、制造方法的技术,应用在半导体器件、电固体器件、辐射控制装置等方向,能够解决减少感光区域面积、增加暗电流与白像素、高漏电流等问题,达到减少光晕现象的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Certain terms are used in this specification and the following claims to refer to specific components, but those with ordinary knowledge in the art should understand that hardware manufacturers may use different terms to refer to the same component. Subsequent claims do not use the difference in name as the method of distinguishing components, but the difference in function of the components as the criterion for distinguishing. The "comprising" mentioned in the entire specification and subsequent claims As an open-ended term, it should be interpreted as "including but not limited to".

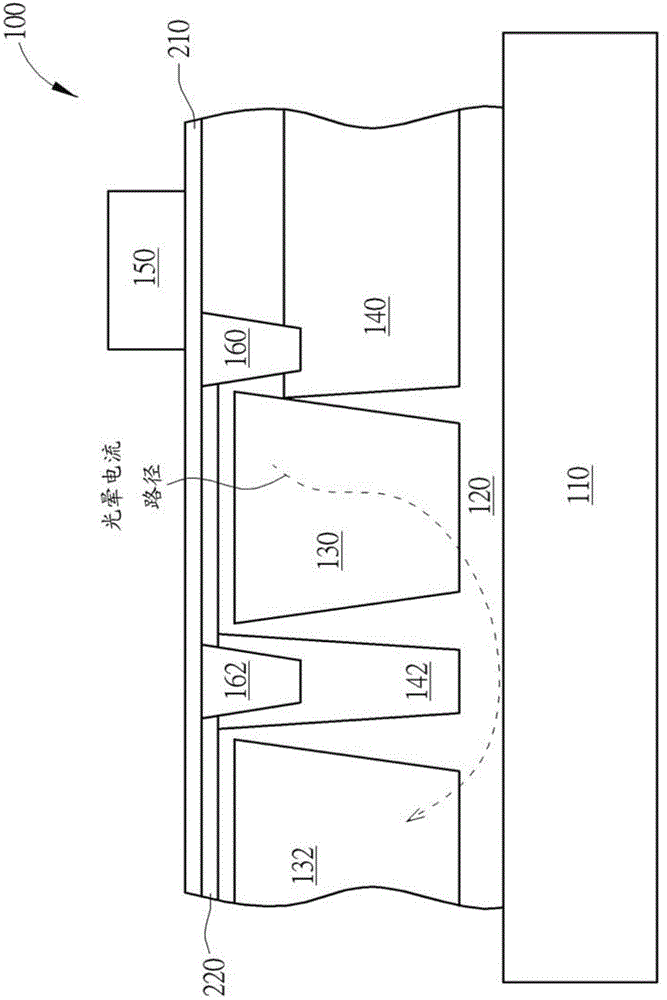

[0050] Please refer to Figure 6 , Figure 6 What is shown is a simplified schematic cross-sectional view of an image sensor 500 according to an embodiment of the present invention, as shown in FIG. Figure 6 As shown, the image sensor 500 includes: a P-type substrate 510, a P-type epitaxial layer (epitaxial layer) 520, two photosensitive regions 530, 532, two P-type well regions 540, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com