A spacer for camera lens with reduced flare phenomenon and manufacturing method thereof

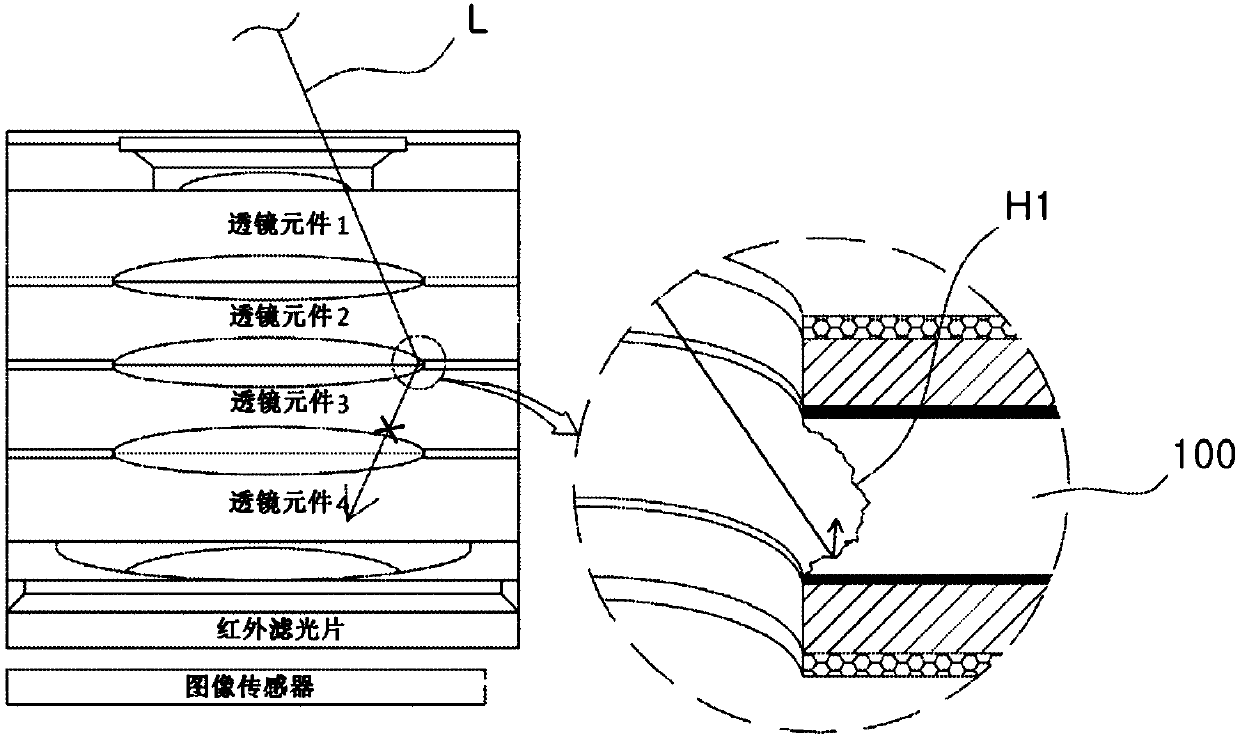

A phenomenon and camera technology, applied in the field of spacers for camera lenses, which can solve the problems of overall image blurring and limited halo prevention, and achieve the effects of preventing peeling, reducing halo phenomenon, and blocking halo phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] 1. First, mix the polyurethane series resin, the isocyanate series curing agent, and the retarder that hinders the intense reaction between the curing agent and the resin at a fixed ratio, and stir it at a speed of about 500 RPM for more than 30 minutes to prepare A primer solution was formed, and the primer solution was coated on a PET film substrate with a thickness of 0.25 μm for the first time.

[0070] At this time, as a coating method, microgravure coating, which can coat a film of 1 μm or less and has a relatively small thickness variation, is used as a method in which the solution filled in the mesh gap of the screen roll is transferred to the film and coated. Method (Micro Gavure Coating). In this embodiment, M200 Mesh produced by Media Engineering is used.

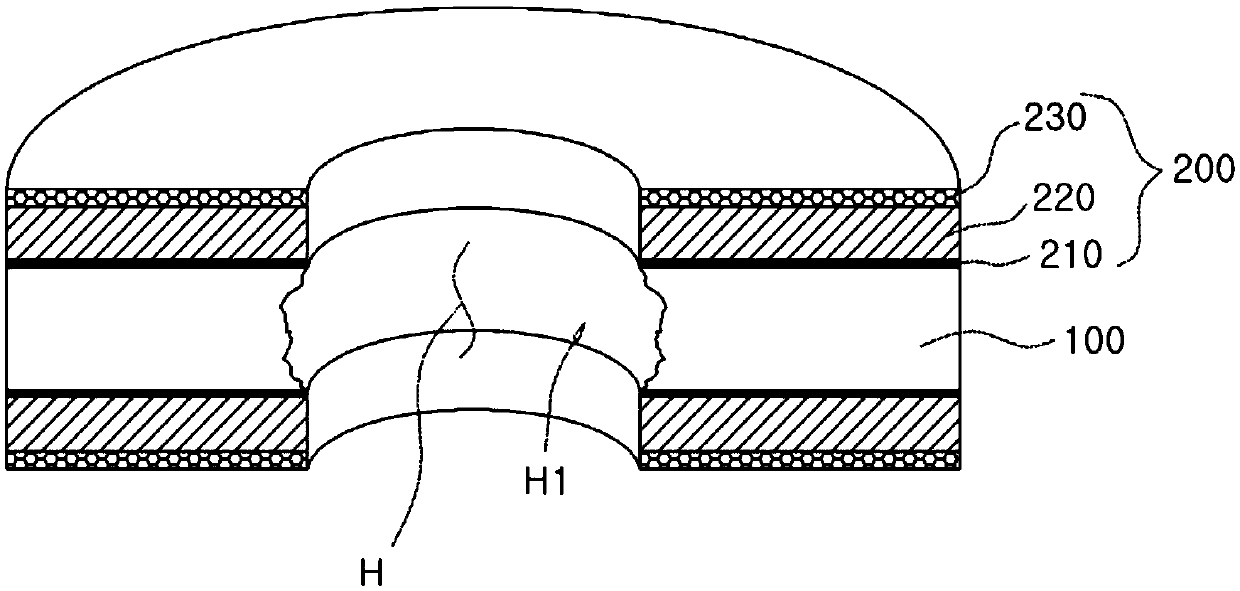

[0071] 2. Next, apply a functional coating on the surface of the base coat for the second time with a thickness of about 4 μm to form a black coating (220) by micro-gravure coating. The functional coating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com