Temperature-control circulating electrolyte supplementing zinc-oxygen battery system

A technology of zinc-oxygen battery and zinc-oxygen battery pack, which is applied in the direction of fuel cell additives, battery pack components, circuits, etc., can solve problems such as evaporation and take away, battery electrolyte loss, and failure to work, and achieve a wide range of applications, The effect of wide application range and low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

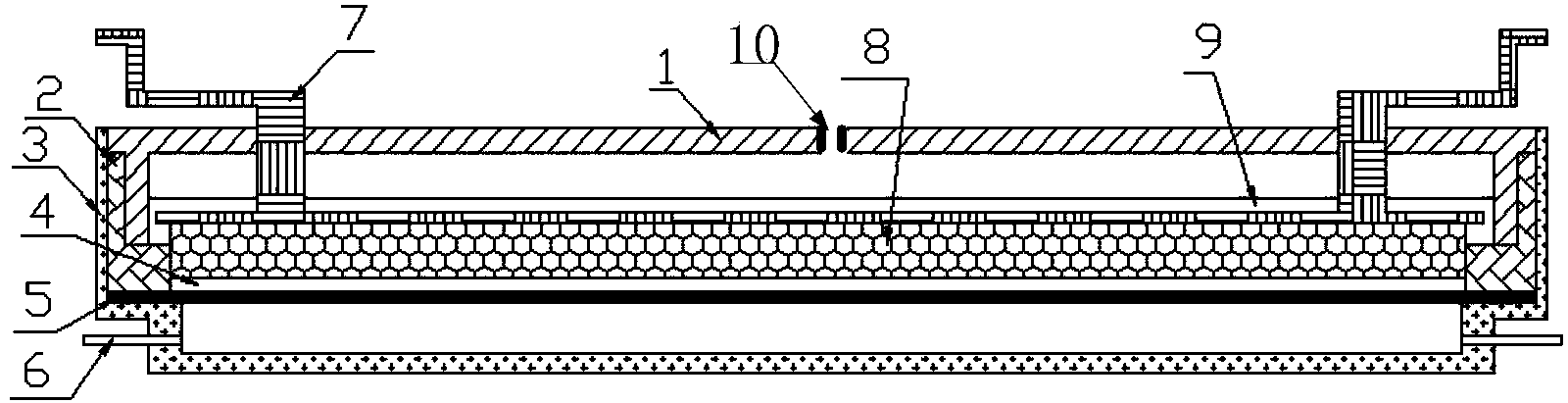

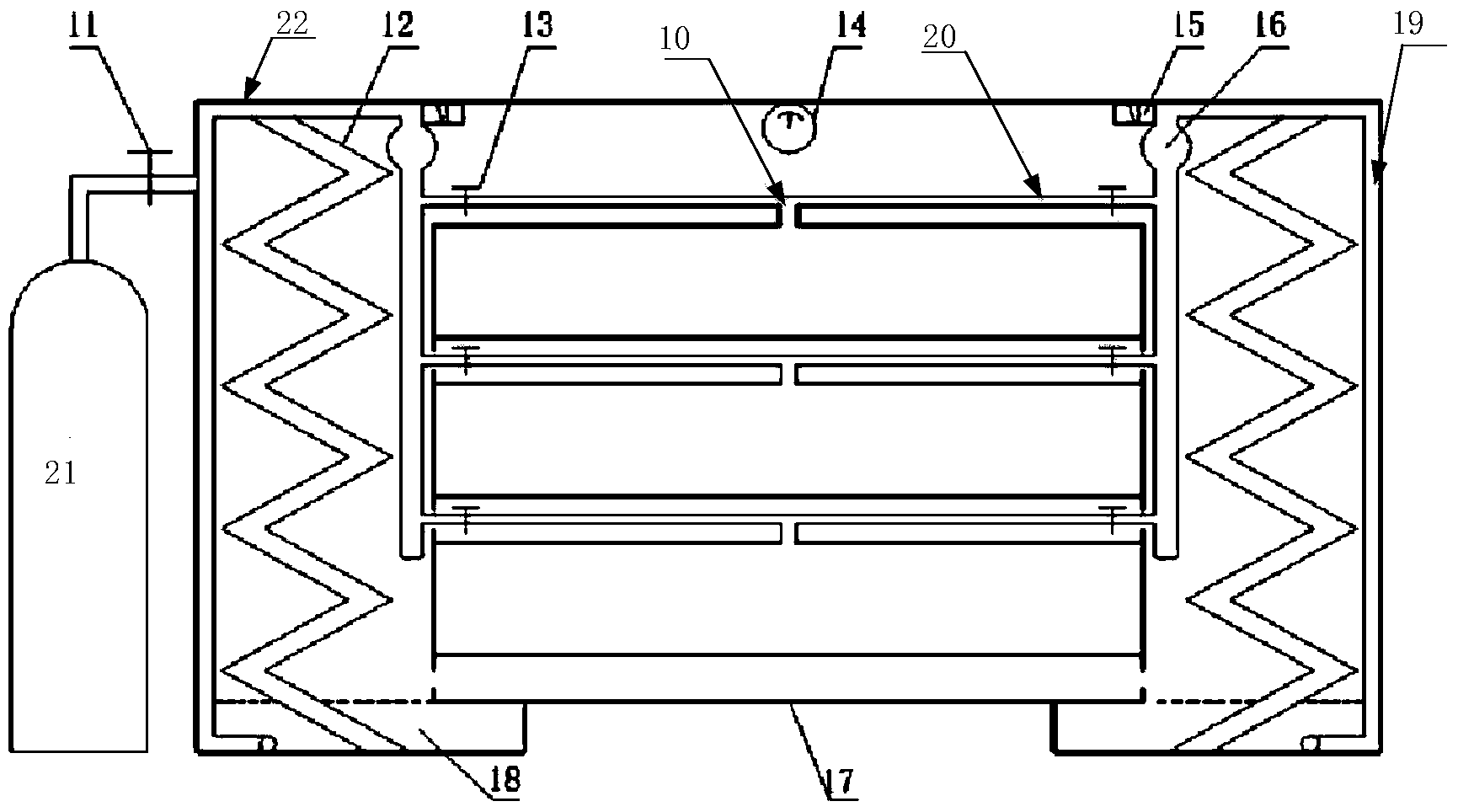

[0016] Combine below figure 2 This embodiment is further introduced.

[0017] A temperature-controlled circulation rehydration zinc-oxygen battery system, including a zinc-oxygen battery pack 17, an oxygen tank 21, and a sealed battery working compartment 22, the zinc-oxygen battery pack 17 is located inside the sealed battery working compartment 22, and the zinc-oxygen battery pack 17 It consists of a plurality of single-cell zinc-oxygen batteries. The bottom of the single-cell zinc-oxygen battery is provided with an oxygen channel 6, and the top is provided with an electrolyte replenishment port 10; the oxygen tank 21 is located outside the sealed battery working compartment 22 and is provided with a valve The pipeline of 11 is connected to the airtight battery work compartment 22, and the airtight battery work compartment 22 is also equipped with a circulating liquid replenishment device, which is symmetrically distributed on both sides of the zinc-oxygen battery group 17,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com