Non-contact power supply transformer for mobile body

A non-contact power supply and moving body technology, applied in the field of transformers, can solve the problems of power supply efficiency reduction and achieve the effect of suppressing leakage magnetic field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

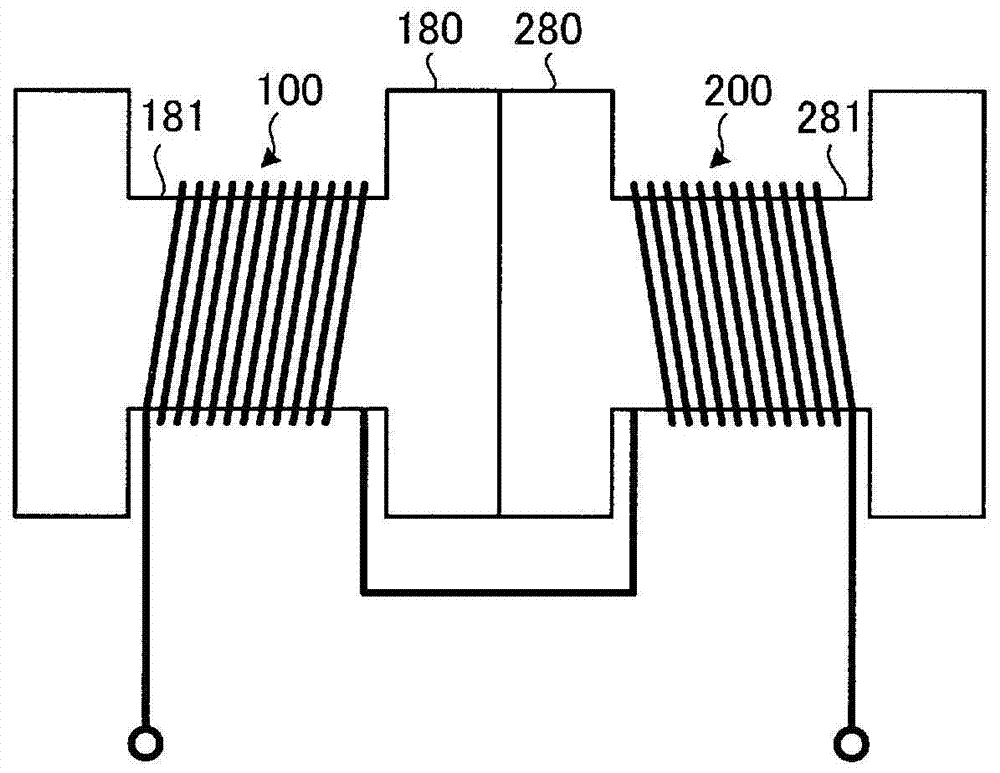

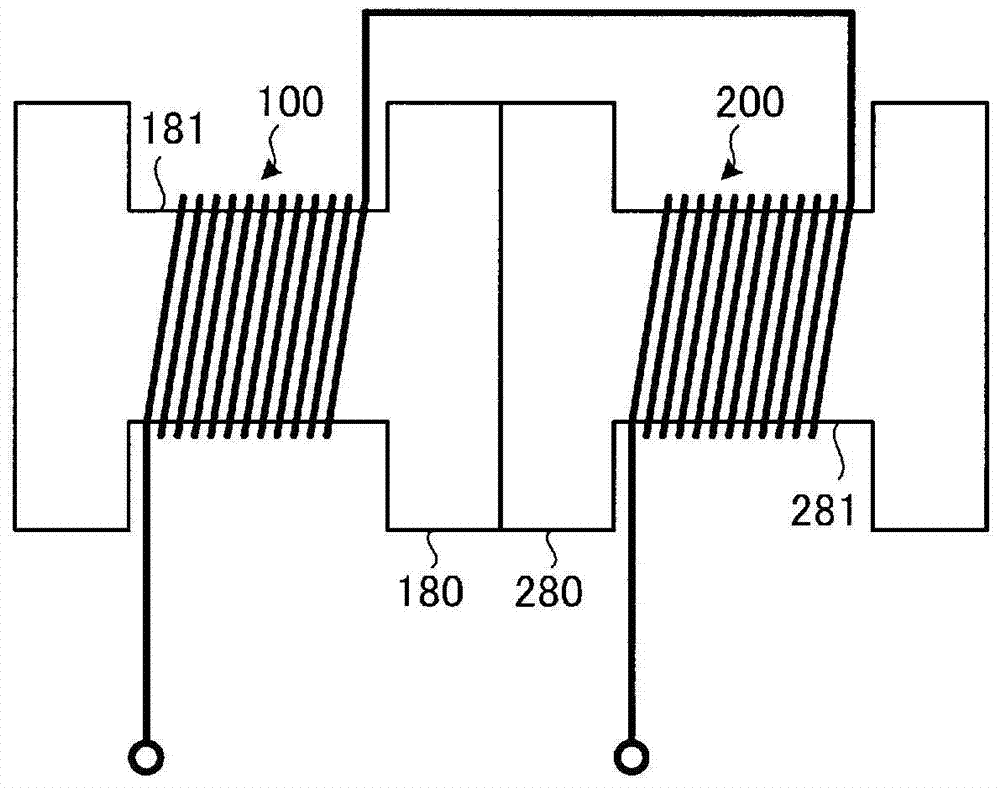

[0072] Figure 1A , Figure 1B A power transmission coil of a mobile body non-contact power supply transformer according to an embodiment of the present invention is schematically shown. The power receiving coil also has the same structure.

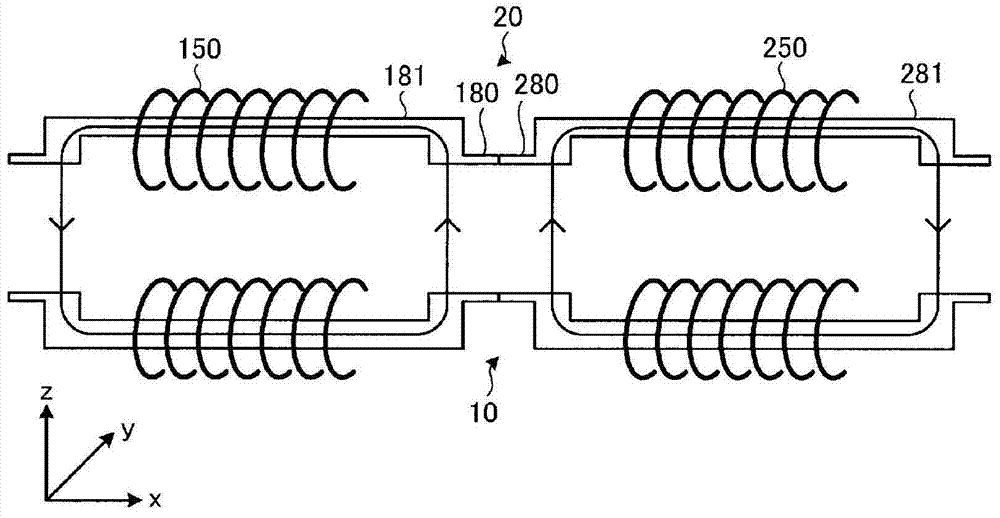

[0073] This power transmission coil is composed of a combined double-wound coil in which two single double-wound coils 100 and 200 are combined.

[0074] The single double-side wound coils 100 and 200 are formed by winding Litz wire around the wound portion of the H-shaped core, specifically, as Figure 7A , Figure 7B As shown, the H-shaped core is formed by a pair of parallel magnetic pole cores 80 and a winding core 81 orthogonal to the magnetic pole cores 80 . Both the pole core 80 and the winding core 81 are ferrite cores.

[0075] The winding part 50 around which the electric wire is wound is attached to the center of the winding core 81 , and both ends of the ferrite plate protruding from both sides of the winding part 50 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com