Environment-friendly bed board machining equipment

A processing equipment and environment-friendly technology, applied in the field of environment-friendly bed plate processing equipment, can solve problems such as affecting the health of production workers, scattering paints, overspraying of paints, etc., and achieve the effects of reducing air pollution, convenient rotation and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

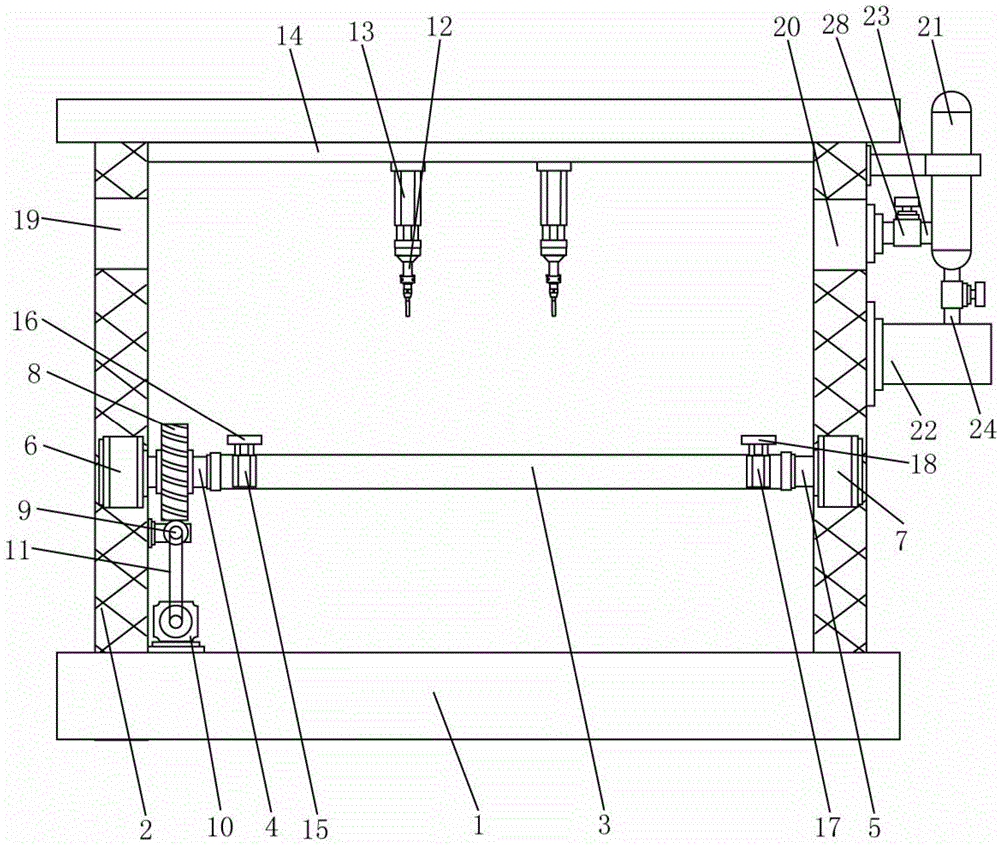

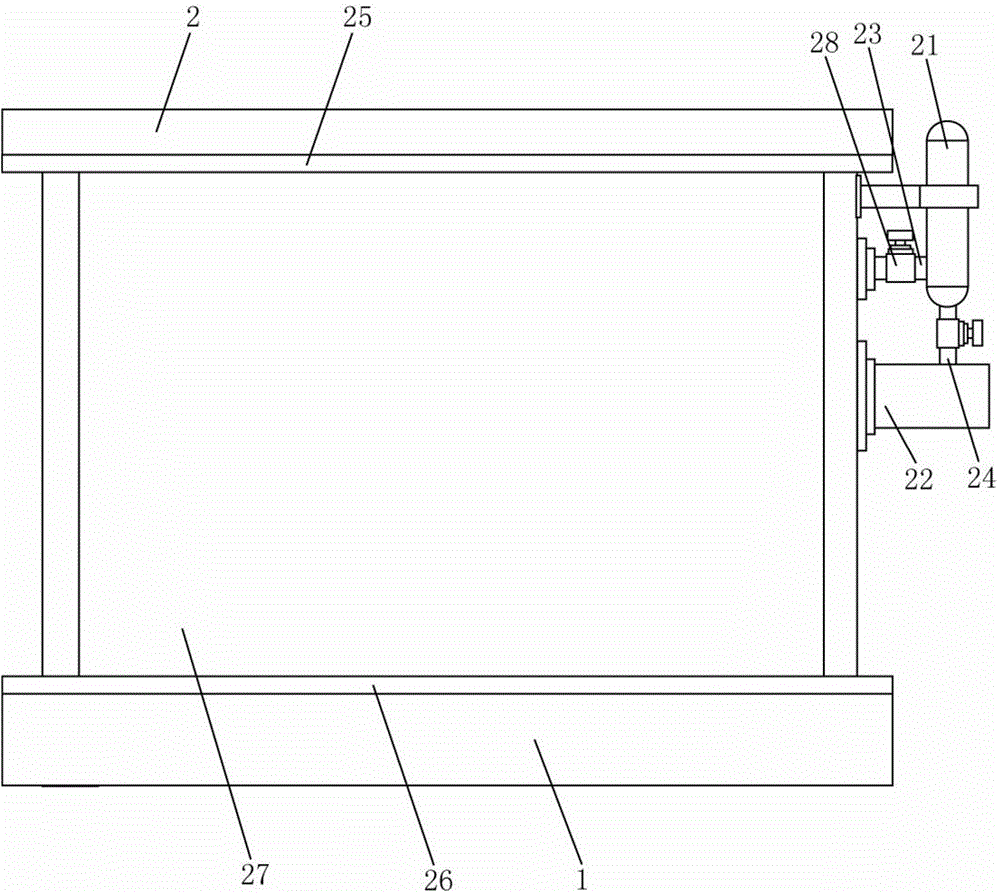

[0024] Such as Figure 1-2 As shown, an environment-friendly bed board processing equipment includes a base 1, a frame 2, a fixed frame 3, a first rotating shaft 4, a second rotating shaft 5, a first rotating shaft bearing 6, a second rotating shaft bearing 7, a turbine 8, and a worm 9 , motor 10, conveyor belt 11, paint spray gun 12, paint spray gun cylinder 13, sliding guide rail 14, air inlet fan 19, air outlet fan 20, condenser 21, collection tank 22, air outlet pipeline 23, recovery pipeline 24, upper Sliding door slideway 25, lower sliding door slideway 26, sliding door 27, frame 2 is installed on the top of base 1, fixed mount 3 is positioned at the middle part of frame 2, and one end of fixed mount 3 links to each other with first rotating shaft 4, fixes The other end of the frame 3 is connected with the second rotating shaft 5, the end of the first rotating shaft 4 is installed in the first rotating shaft bearing 6, the first rotating shaft bearing 6 is installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com