Production technology of 8630 forging pieces for deep sea oil extraction equipment

A production process and equipment technology, applied in the field of production process of 8630 forgings for deep-sea oil production equipment, can solve the problems of coarse grains, internal looseness, micro-cracks, etc., and achieve the effect of high hardness and good impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

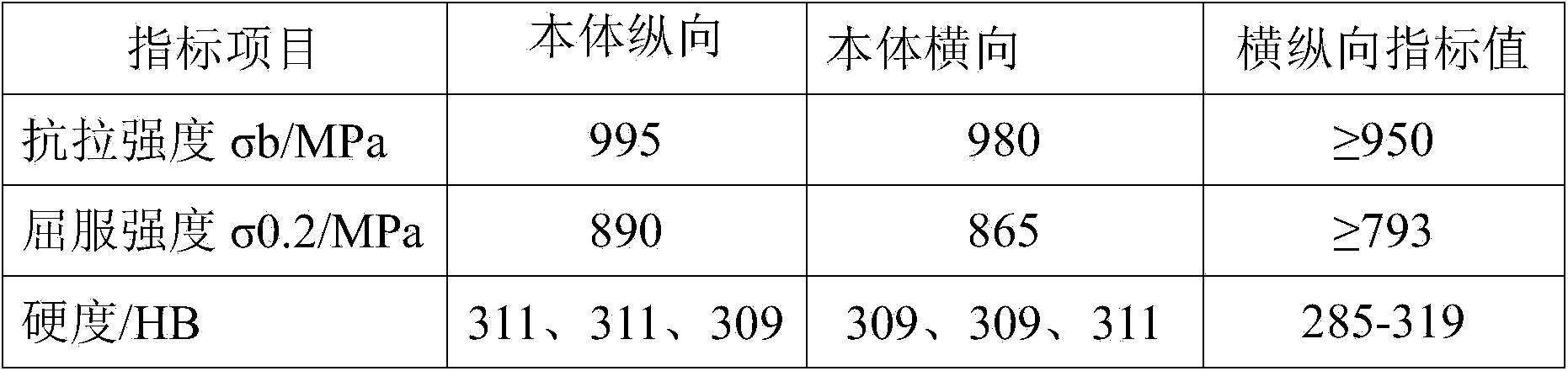

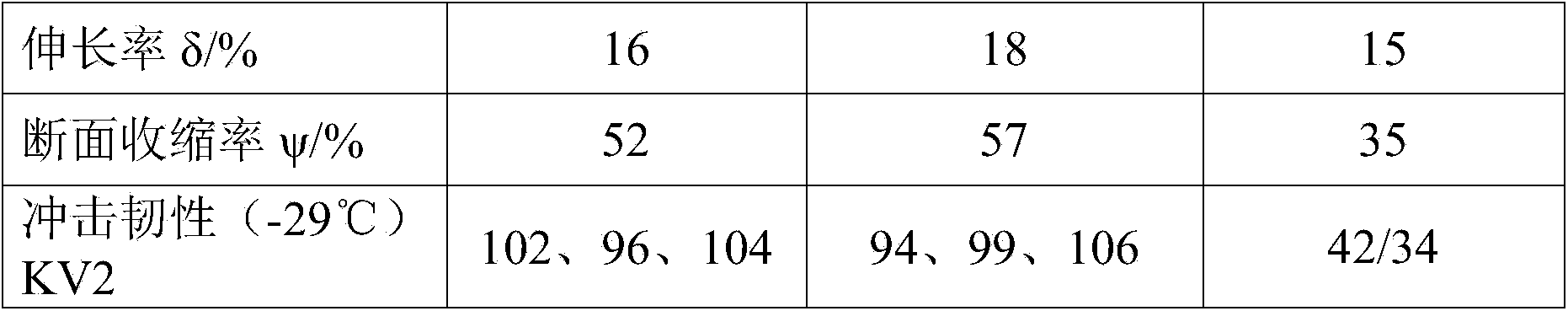

Examples

Embodiment Construction

[0011] The production process of the 8630 forging for deep-sea oil production equipment according to the present invention will be further described in detail through specific examples below.

[0012] (1) Refining formula technology

[0013] 8630 is based on 30CrNiMo by adding V and appropriately increasing Mo to achieve an optimized ratio to improve hardenability and comprehensive mechanical properties, and is used to manufacture forgings with higher comprehensive mechanical properties than 30CrNiMo. Cr, Ni, and Mo are all elements that improve hardenability, and the addition of V is more obvious for grain refinement and hardenability improvement. Cr, Mo, Ni, and V are all strong carbide forming elements, which improve the overall hardenability, refine the structure, and improve the strength and impact toughness.

[0014] (2) Forging technology

[0015] The initial forging temperature of 8630 is 1200°C, and over 1200°C is likely to cause overheating or even overburning. De...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com