Production process of gas meter pipe joint

A gas meter pipeline and manufacturing process technology, applied in the direction of pipes/pipe joints/fittings, threaded connections, sealing surface connections, etc., can solve the problems of product sand holes, air holes, casting process pollution, high energy consumption, etc., to achieve smooth surface, Improve the ability to resist deformation due to temperature difference and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

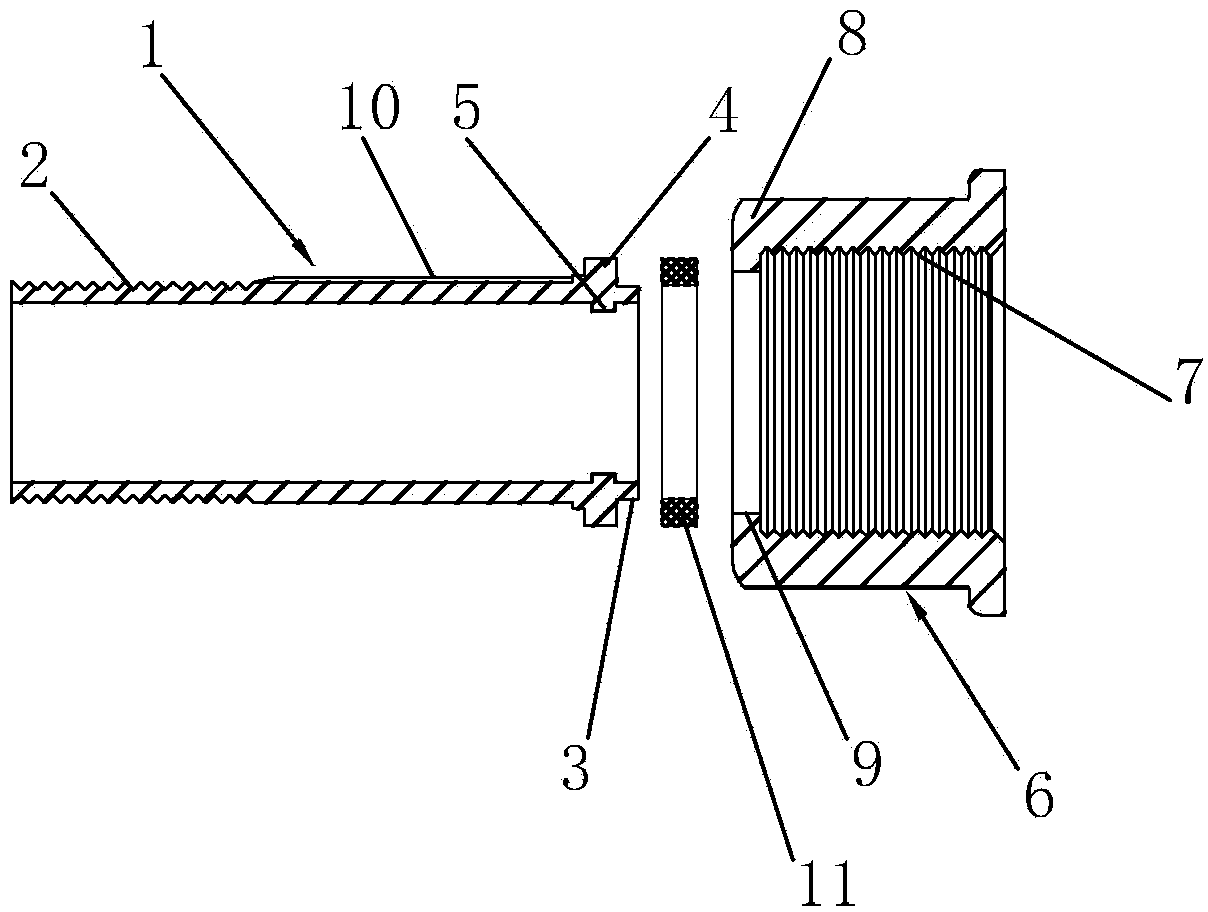

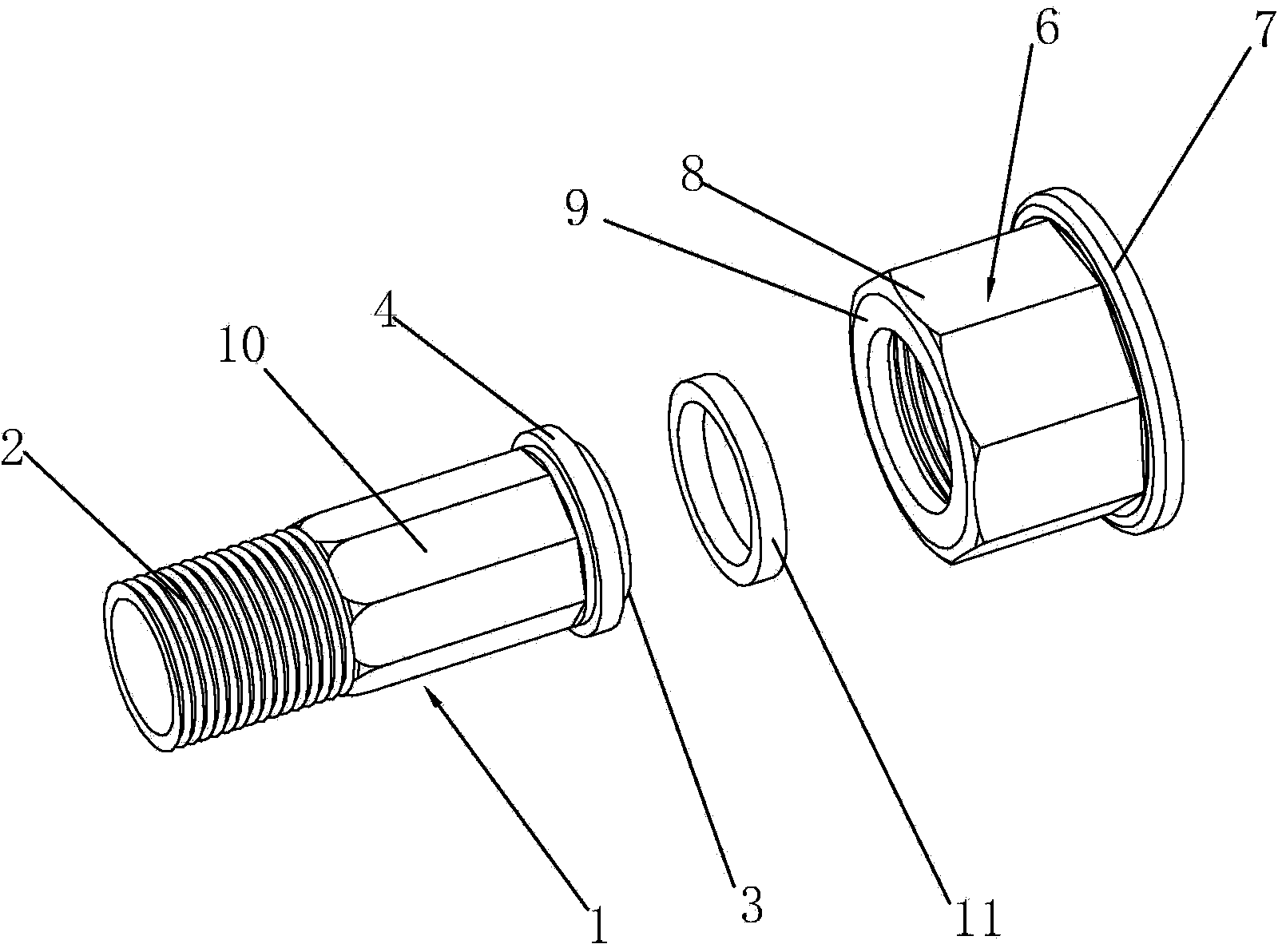

[0041] refer to Figure 1 to Figure 3 The embodiment of the manufacturing process of the gas meter pipe joint of the present invention will be further described.

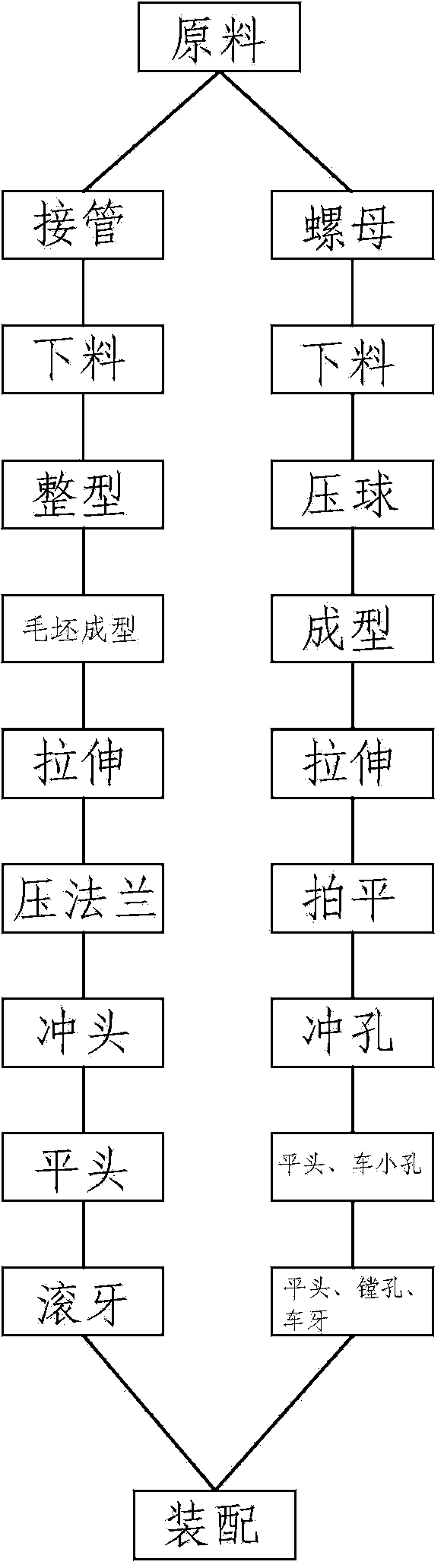

[0042] A manufacturing process of a ball valve for a gas meter pipeline, comprising the following steps:

[0043] A gas meter pipe joint manufacturing process, including the following steps:

[0044] Step 1, Manufacturing Takeover:

[0045] In the cold heading machine mold, a single pipe material is stamped out of the raw material; in the cold heading machine mold, the pipe material is shaped, the pipe contour is cold-headed, the pipe contour is extruded, and the pipe is cold-headed; butt pipe One end is stretched to stretch the circumferential length of the connecting pipe in place; one end of the valve body profile is cold-headed to make a flange end; on a lathe, the other end is turned to produce a flat end surface; in the thread rolling machine, Process external threads on the outside of the flat end face;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com