Aero-engine multistage rotor and stator unit body positioning and hoisting device

An aero-engine and rotor-stator technology, which is used in transportation and packaging, workpiece clamping devices, load-hanging components, etc., can solve the problems of affecting the balance effect of the rotor and the probability of collision and wear, and achieves easy promotion, radial axis The effect of firm orientation and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

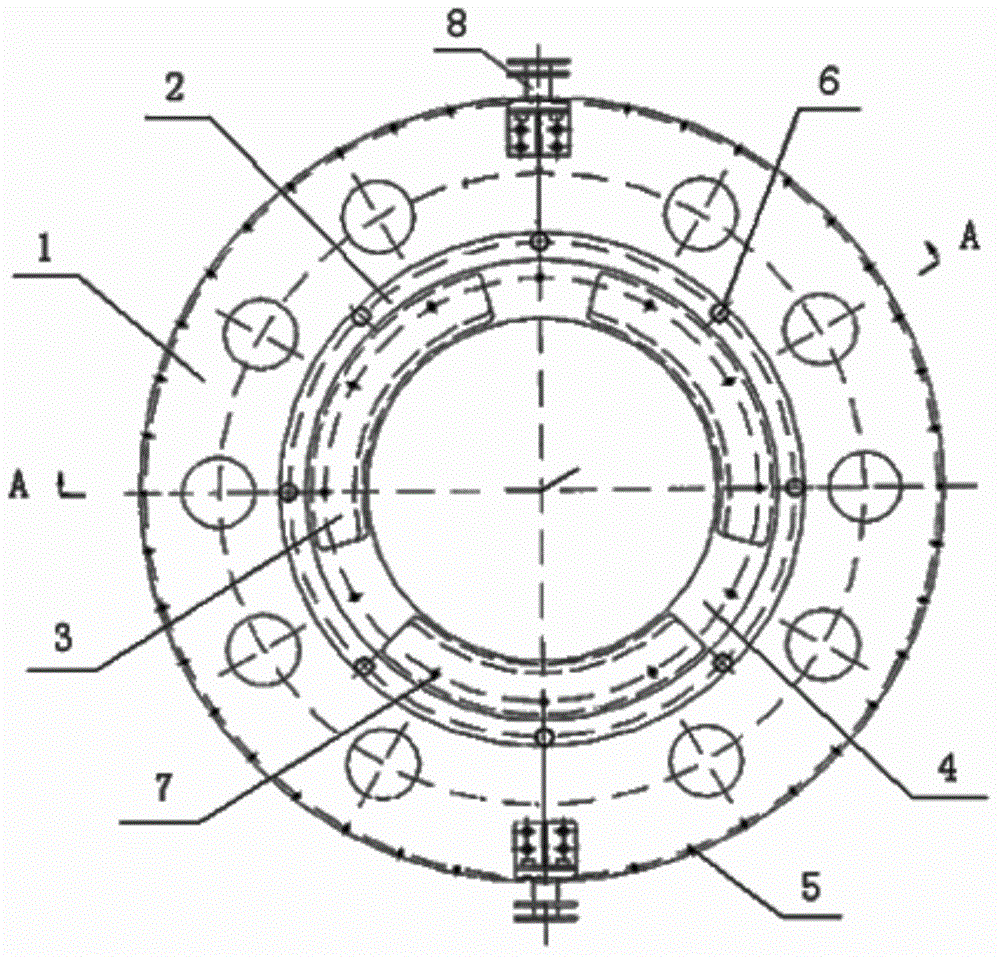

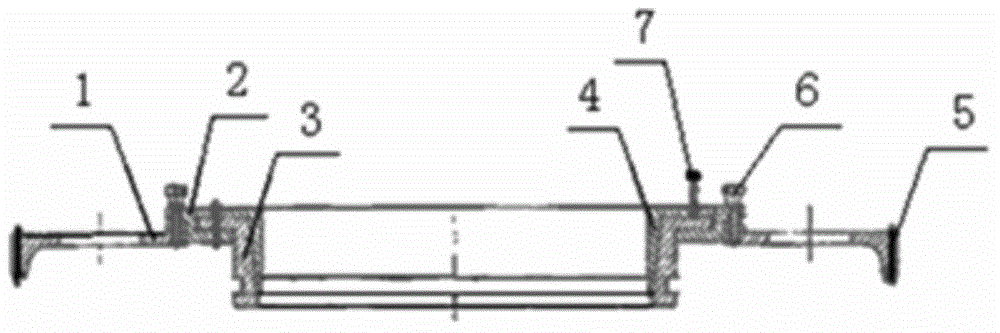

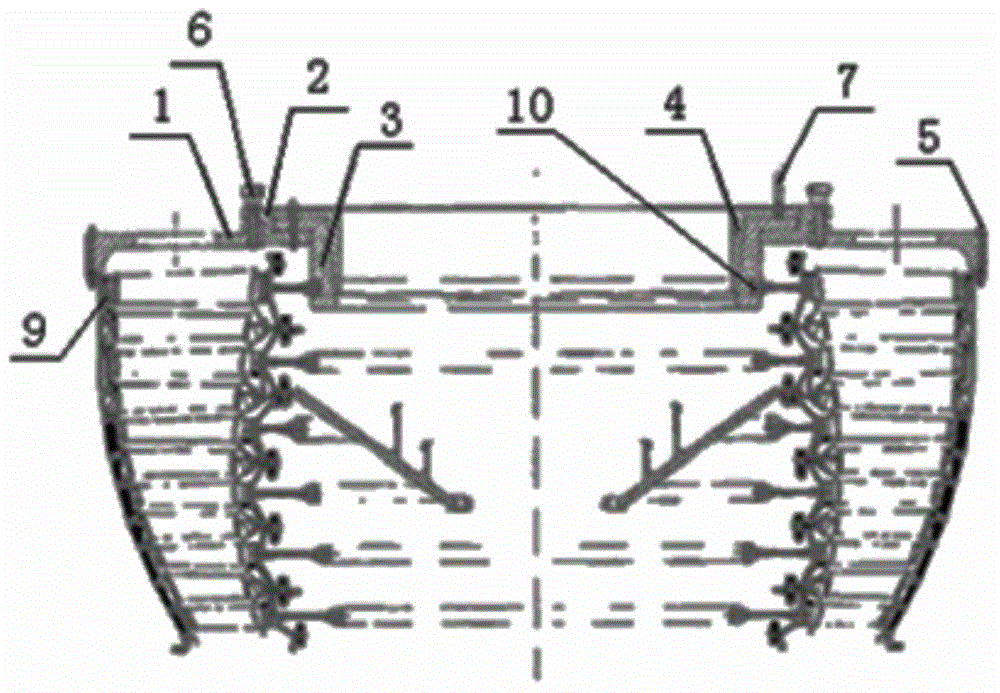

[0017] Such as figure 1 , 2 , 3, a device for positioning and hoisting the multi-stage rotor-stator unit of an aero-engine, including a process case 1, a trunnion 8, a bolt one 5, an adapter plate 2, a bolt two 6, a fixed plate 3, and an expansion core Ring 4 and bolt three 7, the process casing 1 is connected with the stator casing rear mounting edge 9 of the rotary stator unit body through bolt one 5; two trunnions 8 are arranged on the process casing 1; the rotary The adapter plate 2 is arranged inside the process casing 1, and the transfer plate 2 is connected to the process casing 1 by bolts 2 6; the fixed plate 3 is arranged inside the adapter plate, and the fixed plate It consists of three segments, the inner edge of the segment is a slope, and the outer edge of the segment is provided with a U-shaped groove, and the U-shaped groove is matched with the spoke plate 10 of the six-stage turbine disk of the rotor-stator unit body The expansion core ring 4 is arranged insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com