Glue cutting device for cutting glue materials by using gear rotation

A transmission device and gear technology, which is applied in the field of rubber cutting device, can solve the problems of not sharp knife edge and affect work efficiency, and achieve the effect of saving manpower and material resources and increasing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

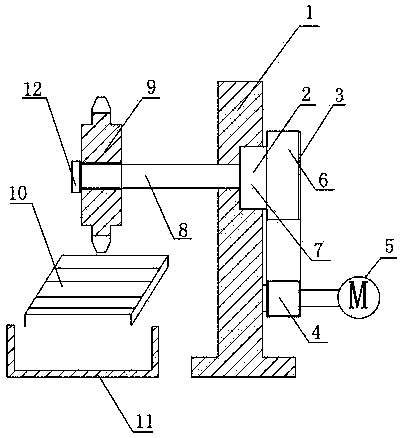

[0015] Such as figure 1 As shown, a rubber cutting device that utilizes gear rotation to cut rubber materials includes a frame 1, a transmission device 2 fixed on the frame 1, and a driving wheel 4 connected to the transmission device 2 through a belt 3. One end of the wheel 4 is fixed on the frame 1, and the other end is connected with the motor 5; the transmission device 2 includes a transmission wheel 6 and a rotating bearing 7 connected with the transmission wheel 6; also includes a rotating shaft 8 connected with the rotating bearing 7; It includes a gear 9 connected to one end of the rotating shaft 8 .

[0016] In this embodiment, the motor 5 is connected to the driving wheel 4, and the driving wheel 4 is connected to the transmission wheel 6 through the belt 3. When the motor 5 is started, the driving wheel 4 will drive the transmission wheel 6 to rotate, and the rotation of the transmission wheel 6 will drive the gear 9 High-speed rotation, the high-speed rotation of ...

Embodiment 2

[0018] On the basis of Embodiment 1, this embodiment further includes a roller conveying device 10 arranged below the gear 9 .

[0019] The roller conveying device 10 arranged under the gear 9 can convey the rubber material, so that the rubber material is automatically transported to the bottom of the gear to be cut by the gear, and the roller conveying device 10 can convey the cut rubber material, which increases the work efficiency.

Embodiment 3

[0021] On the basis of Embodiment 2, this embodiment further includes a material storage frame 11 arranged at the end of the roller conveying device 10 .

[0022] The setting of the material storage frame 11 makes the rubber material to be cut automatically fall into the material storage frame 11, without manual picking, saving a lot of manpower and material resources.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com