Automatic reciprocating scraping type bamboo skin removing device

An automatic reciprocating and reciprocating drive technology, which is applied in the direction of plant material machining, mechanical equipment, etc., can solve the problems of damaging the toughness of bamboo, high manual labor intensity, and poor safety, so as to retain toughness, improve work efficiency, and reduce manual labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

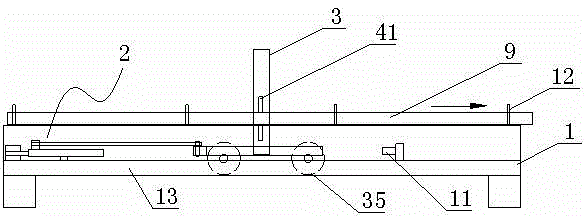

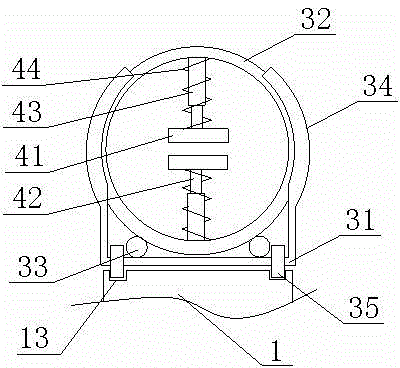

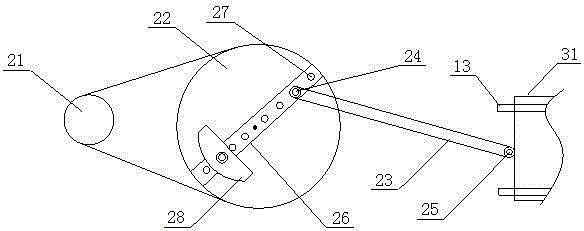

[0020] As shown in the figure (the arrow in the figure indicates the advancing direction of the bamboo 9), the automatic reciprocating scraping bamboo green removal device of this embodiment includes a frame 1, a knife holder, a knife holder reciprocating drive mechanism 2 and a knife holder rotating drive mechanism 3. , The tool post rotation driving mechanism is composed of a base 31, a circular support 32, and a drive motor 33. The circular support 32 is located above the base 31. Both sides of the base 31 are provided with arcs that limit the position of the circular support 32. Limit slot 34; there are two drive motors 33, symmetrically fixed on both sides of the base 31, the motor shaft of the drive motor 33 drives the circular bracket 32 through gears (the outer circumference of the circular bracket 32 is provided with matching gears) on the base 31 Rotation; The base 31 is connected to the reciprocating drive mechanism 2 of the tool holder, and a guide mechanism is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com