Micro-nano holographic anti-counterfeiting film for paper certificates, and production process and application thereof

A holographic anti-counterfeiting, micro-nano technology, applied in the direction of layered products, metal layered products, information-carrying cards, etc., can solve the problems of easy cutting and counterfeiting, large initial investment, and small amount of intuitive information, and achieve cursor tracking Technical difficulties, preventing fraudulent behavior, and improving the effect of technical difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

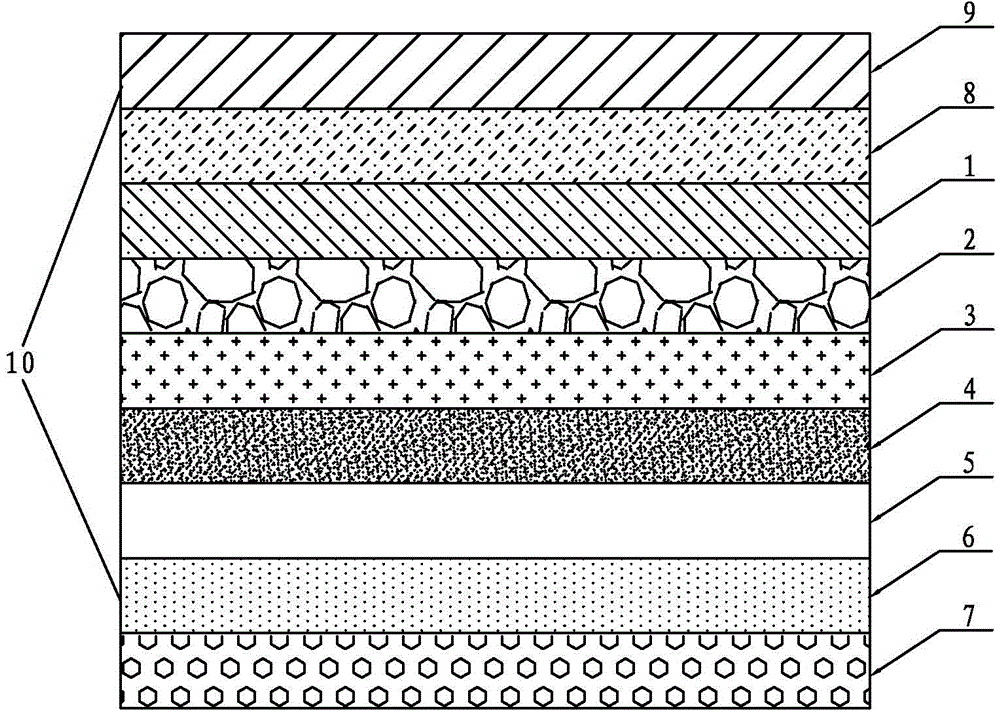

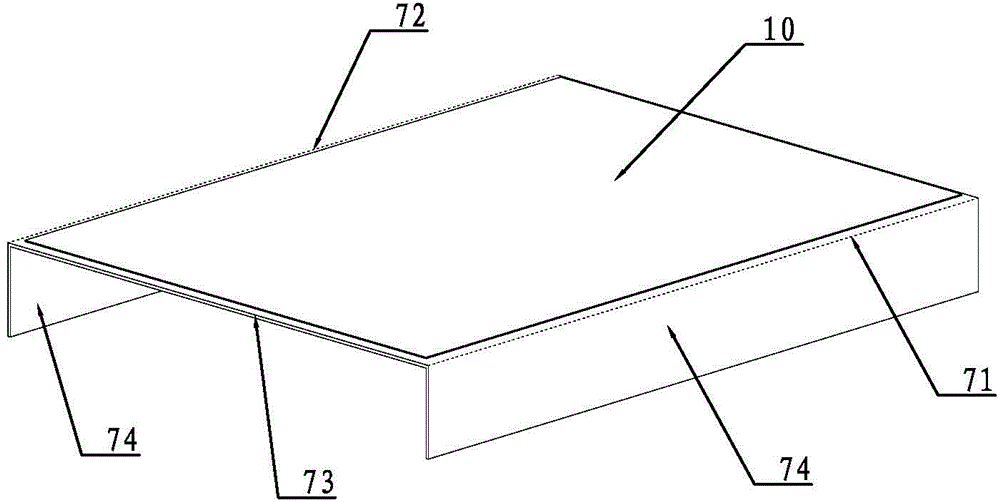

[0040] Such as Figure 1-2 As shown, a micro-nano holographic anti-counterfeiting film for paper documents includes a micro-nano holographic base film 1, and the front of the micro-nano holographic base film 1 is sequentially superimposed with an information layer 2, a vacuum aluminum layer 3, and a positioning aluminum washing protection film. Layer 4, transparent medium layer 5, main adhesive layer 6 and anti-adhesive base paper 7, the back of the micro-nano holographic base film 1 is sequentially superimposed with an adhesive layer 8 and a protective film 9; wherein, the micro-nano holographic base film 1 is a PET film with a thickness of generally 12-15 μm, and the protective film 9 is also a PET film with a thickness of generally 35-50 μm. In this embodiment, the thickness of the micro-nano holographic base film 1 is selected to be 12 μm, and the thickness of the protective film 9 is selected to be 35 μm.

[0041] The anti-adhesive backing paper 7 is provided with two pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com