Hull trap

A technology for repairing leaks and hulls, which is applied to the safety of ships, ships, transportation and packaging, etc. It can solve the problems of water leakage in the gap, long time, and difficulty in pressing the plugging equipment, so as to reduce water pressure, simple structure, and rapid leak repair Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: structure, position and function of each component.

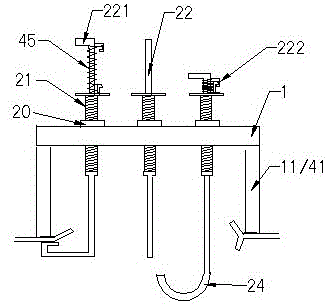

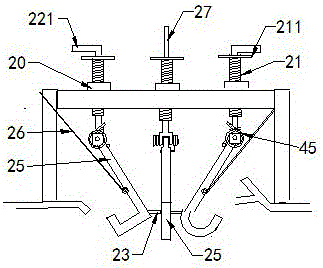

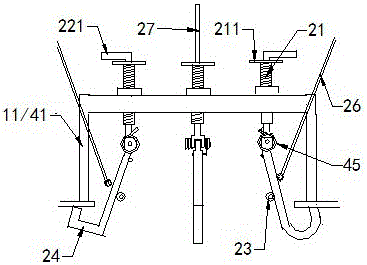

[0038] As shown in the figure, a ship hull leakage repair box includes a box body 1 , a barb fastening mechanism 2 , a drain valve mechanism 3 , and a sealing mechanism 4 .

[0039] 1. Box body.

[0040] like Figure 6 , Figure 9 , Figure 13 , Figure 16 As shown, it includes panel 10, riser 11, frame edge 12, groove 13, gasket 14, lifting handle 15, observation window 16, lighting equipment 17, drain valve pipe interface 18, and the box is round or square , the periphery of the panel 10 is fixedly connected with the circular equal-height vertical plate 11 extending downward to form a cavity, the vertical plate is perpendicular to the panel or inclined outward at a small angle, the bottom surface is open, and the lower end of the vertical plate has a magnetic The flat frame edge 12 has a groove 13 on the frame edge, a built-in gasket 14, a sealing observation window 16 and lighting equipment 17 c...

Embodiment 2

[0059] Embodiment 2: Connection relationship and working principle of each component.

[0060] When plugging, cover the leakage repair box at the damaged part. When the water pressure is high, the valve plate can be opened for decompression operation, and then closed after being fixed, or the valve plate can be closed for operation.

[0061] like figure 1 , Figure 4 As shown, when the rotating rod is used for fixing, the direction of the inner rotating rod is turned inward, press down the inner rotating rod to buckle the hook on the top of the rod with the upper end of the coiled tube, the opening of the box is placed at the hole, and the curved rod is turned upside down. The hook protrudes out of the hole and exceeds the remnant ship plate, then turn the direction bar to make the barb outward, open the hook 222, and the barb head of the inner turning bar is stuck on the outer shell of the damaged edge under the action of the elastic force. Shake the turntable 221 to move t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com