An automatic control glass bottle detection system

A technology for controlling glass bottles and detection systems, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of secondary pollution of products, high labor intensity of staff, and easy occurrence of missed inspections, so as to reduce personnel investment and labor intensity , Optimize the production process, improve the effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

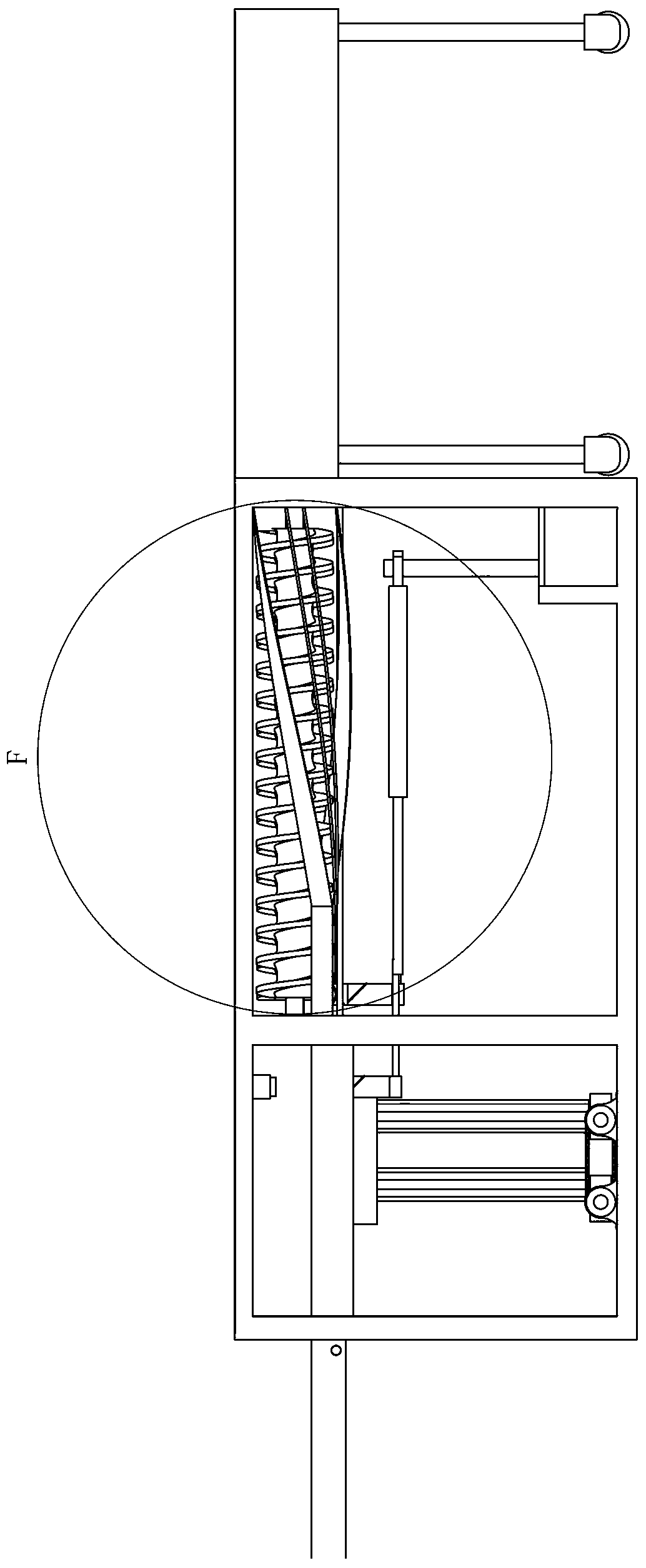

[0039] as attached Figure 1-18 Shown is an embodiment of the present invention.

[0040] The invention is composed of a PLC programmable controller, an automatic bottle detection and rejection system, an annealing device and an automatic bottle sorting system;

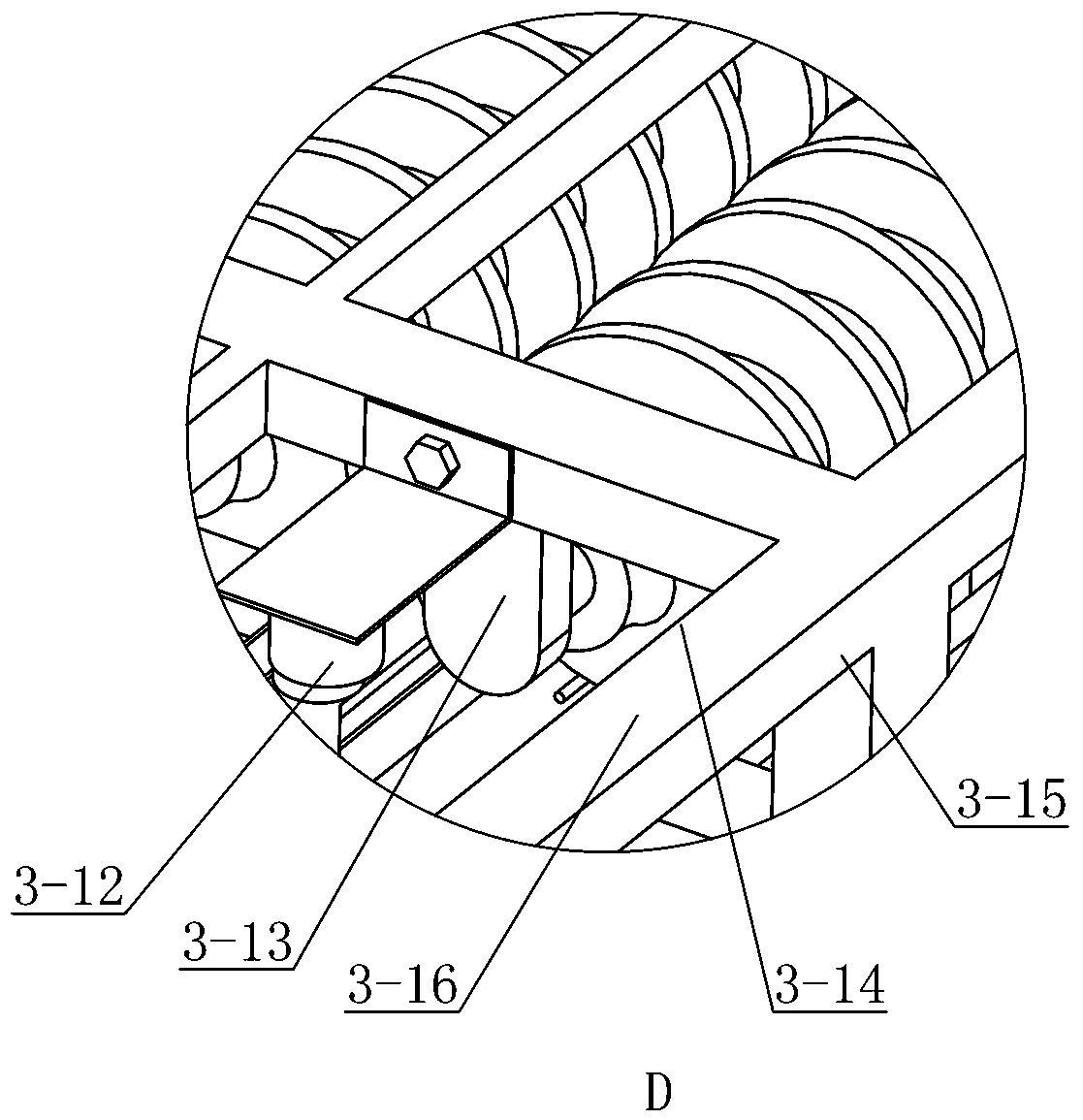

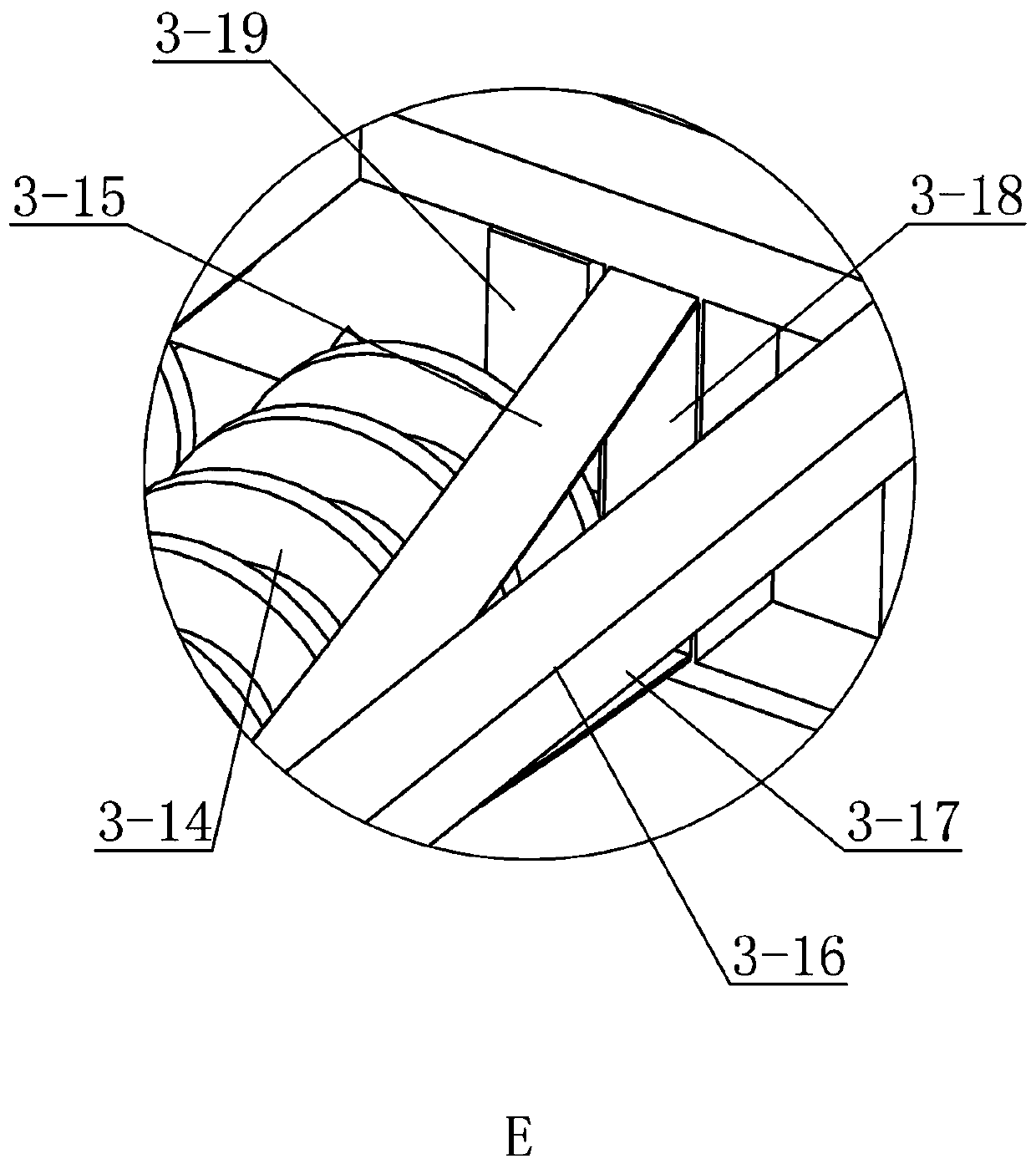

[0041] The automatic bottle detection and elimination system includes a detection system frame 1-1, a detection end bottle transport device arranged on the detection system frame 1-1, and an entry track 1-2 disposed at the front end of the detection end bottle transport device. , the shunt buffer device arranged on the rear end of the bottle conveying device and the detection end monitoring camera 1-5 arranged on the bottle conveying device, the height detection and rejecting device and the wall thickness detection and rejecting device, the detection end monitoring camera 1-5 and The corresponding interface of the PLC programmable controller is connected;

[0042]The detection end bottle transport device consists of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com