Driving tank of calibrating-free dosing machine and calibrating-free numerical control dosing machine

A dosing machine and calibration-free technology, which is applied in liquid distribution, transportation or transfer devices, special distribution devices, packaging, etc., can solve the problems of solenoid valve or metering pump corrosion, flow rate difference, and inability to measure, and achieve acid and corrosion resistance The effect of increasing the service life, improving the service life, and improving the output accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to describe the technical content, structural features, goals and effects of the present invention in detail, the following examples are given to describe the embodiments in conjunction with the accompanying drawings.

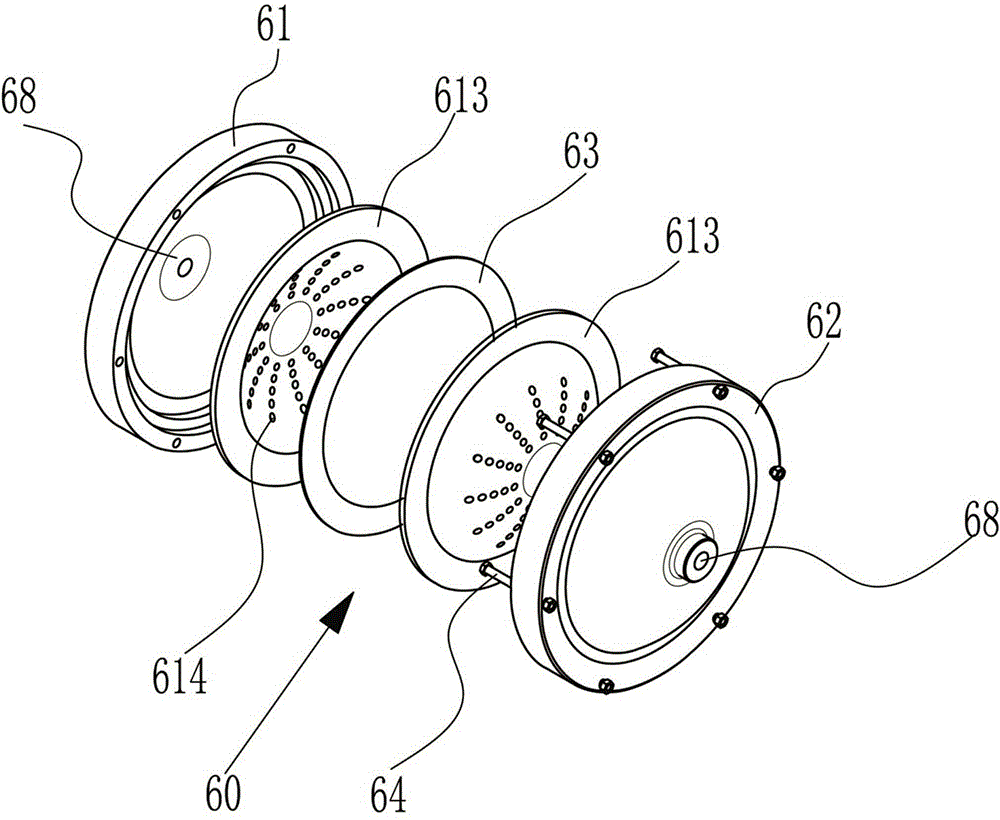

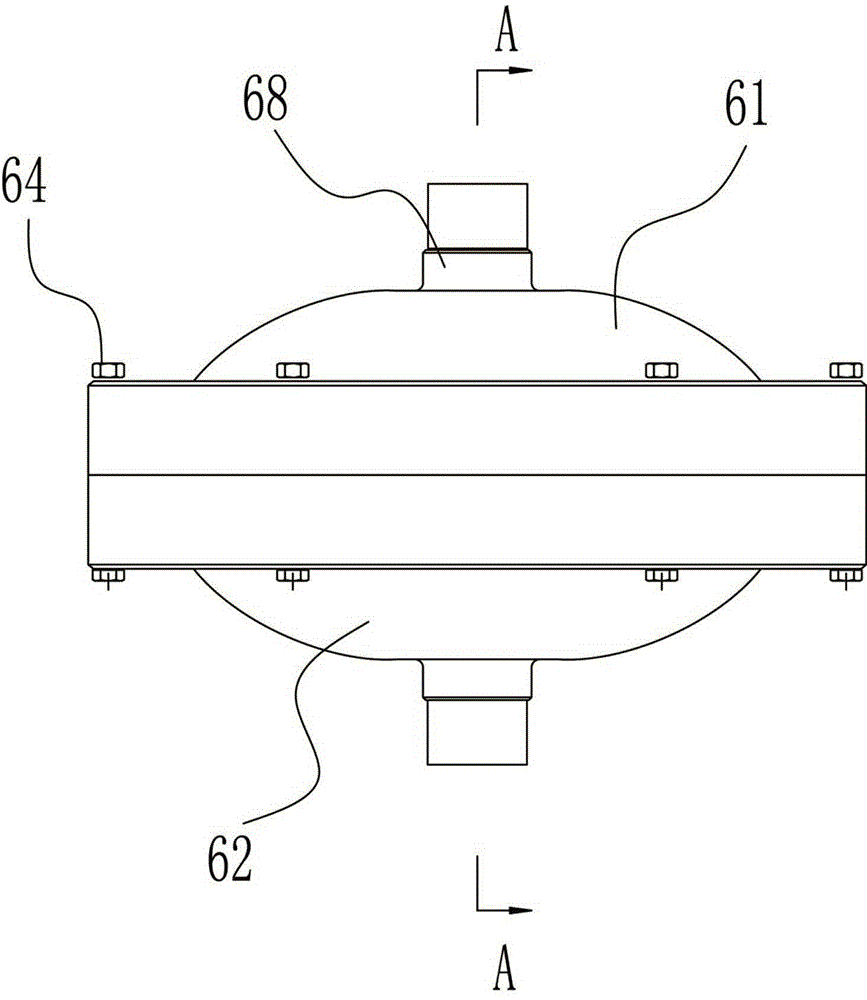

[0027] see figure 2 shown, combined with Figure 3 to Figure 5 As shown, the present invention provides a driving tank for a calibration-free dosing machine, comprising a hollow upper cover 61 and a lower cover 62, an elastic driving diaphragm 63 and a locking bolt 64, the upper cover 61 and the lower cover 62 corresponds to and is locked by locking bolt 64 to form a closed accommodating space, an opening 68 is respectively provided on the upper cover body 61 and the lower cover body 62, and the elastic driving diaphragm 63 is installed in the accommodating space It is divided into two drug storage chambers 611 and water storage chambers 612 with equal volumes. When the power water enters the water storage chamber 612 through the opening 68 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com