A method for extracting DHA algae oil and algae protein from algae

A technology of algae and algae oil, which is applied in the preparation methods of peptides, chemical instruments and methods, fat oil/fat production, etc., can solve the problems of low extraction rate of DHA algal oil and its algal protein, and achieve mild conditions and improve the extraction rate. , to avoid damaging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

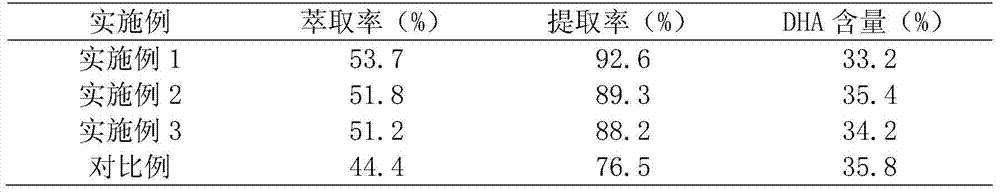

Examples

Embodiment 1

[0050] A method for extracting DHA algae oil and algae protein from algae, comprising the steps of:

[0051] (1) Centrifuge the algae fermentation liquid through a disc centrifuge, the centrifugation conditions are 3000rpm, 3m 3 / h, take the precipitate, and prepare the bacterial liquid; then add absolute ethanol to the bacterial liquid, the weight-to-volume ratio of the bacterial liquid to absolute ethanol is 1:1, unit kg / L, let stand for 30min, and then Under the condition of temperature and pressure of 90Mpa, high-pressure homogeneous wall breaking was carried out, and the wall was broken 3 times in a cycle to obtain the broken bacteria liquid;

[0052] The preparation steps of the algae fermentation liquid are as follows:

[0053] 1. Get the algae and inoculate it in the activation medium, activate and cultivate it for 24 hours at 30°C to obtain the activated strain;

[0054] II, inoculate 10% by weight of the activated strains prepared in step I in the fermentation medi...

Embodiment 2

[0065] A method for extracting DHA algae oil and algae protein from algae, comprising the steps of:

[0066] (1) Centrifuge the algae fermentation liquid through a disc centrifuge, the centrifugation conditions are 3000rpm, 3m 3 / h, take the precipitate, and prepare the bacterial liquid; then add absolute ethanol to the bacterial liquid, the weight-to-volume ratio of the bacterial liquid and absolute ethanol is 0.5:1, the unit is kg / L, let stand for 30min, and then in 20 Under the temperature of ℃ and the pressure of 80Mpa, high-pressure homogeneous wall breaking was carried out, and the wall was broken 4 times in a cycle to obtain the broken bacteria liquid;

[0067] The preparation steps of the algae fermentation liquid are as follows:

[0068] 1. Get algae and inoculate them in the activation medium, and activate and cultivate them for 28 hours at 28°C to obtain activated strains;

[0069] II, inoculate the activated bacterial classification that step I makes by 5% by wei...

Embodiment 3

[0080] A method for extracting DHA algae oil and algae protein from algae, comprising the steps of:

[0081] (1) Centrifuge the algae fermentation liquid through a disc centrifuge, the centrifugation conditions are 3000rpm, 3m 3 / h, take the precipitate, and prepare the bacterial liquid; then add absolute ethanol to the bacterial liquid, the weight-to-volume ratio of the bacterial liquid to absolute ethanol is 2:1, the unit is kg / L, let stand for 30min, and then Under the condition of temperature and pressure of 120Mpa, high-pressure homogeneous wall breaking is carried out, and the wall breaking is circulated twice to obtain the broken bacteria liquid;

[0082] The preparation steps of the algae fermentation liquid are as follows:

[0083] 1. Get the algae and inoculate them in the activation medium, and activate and cultivate them for 20 hours at 32°C to obtain the activated strains;

[0084] II, inoculate the activated bacterial classification obtained in step I in the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com