Molybdenum carbide catalyst as well as preparation method and application thereof

A molybdenum carbide and catalyst technology, applied in the field of polyurethane, can solve the problems of poor thermal insulation of polyurethane, poor biological straw activity, low filling amount, etc., and achieve the effects of good thermal insulation performance, high compressive strength, and optimized electronic structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

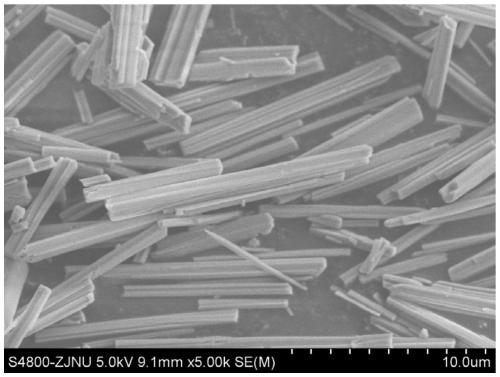

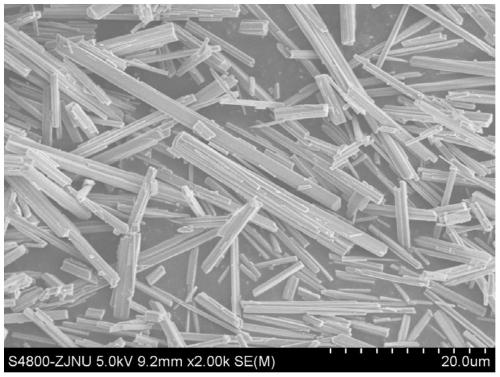

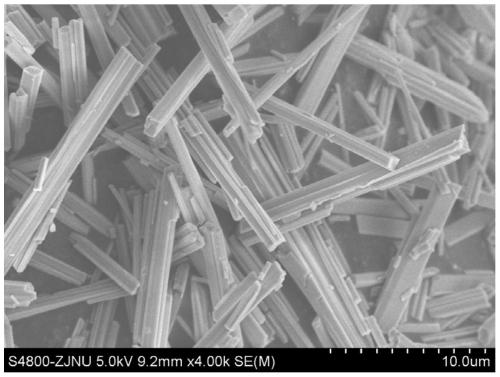

[0062] Embodiment 1-8 provides a kind of molybdenum carbide catalyst and preparation method thereof, each parameter in molybdenum carbide and preparation method is shown in Table 1; The molybdenum carbide catalyst in embodiment 1-8 is respectively marked as A, B, C, D , E, F, G, H;

[0063] The preparation method of molybdenum carbide catalyst comprises the steps:

[0064] After molybdenum trioxide, imidazole compound and water are mixed and reacted for 12 hours, the precursor of molybdenum carbide is obtained after filtering and drying;

[0065] The molybdenum carbide precursor is first calcined in a hydrogen atmosphere for 2 hours, then the gas is switched to an inert gas, and the temperature is raised to a certain temperature for the second calcining. The calcining time is 6 hours, and then the molybdenum carbide catalyst is obtained after cooling down to room temperature.

[0066] Each parameter in the preparation method of table 1 embodiment 1-8 molybdenum carbide cataly...

Embodiment 9-24

[0071] Embodiment 9-24 provides a kind of preparation method of biopolyol, respectively adopts the molybdenum carbide catalyst prepared in embodiment 1-8 as the catalyst for preparing biopolyol, and the settings of specific parameters are shown in Table 2; biopolyol The preparation method comprises the following steps,

[0072] Corn stalks, molybdenum carbide catalysts, catalytic aids and 100ml of solvent are reacted under anaerobic conditions (passing nitrogen), then cooled to room temperature, filtered, rotary steamed, and biopolyols are obtained after removing residues and solvents; wherein corn stalks, The type, amount and setting of reaction conditions of molybdenum carbide catalyst and catalytic promoter are shown in Table 2.

[0073] Parameters in the preparation method of table 2 embodiment 9-24 biopolyols

[0074]

[0075]

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com