Alloy nanocage catalyst, and preparation method and application thereof

A technology of alloy nano and catalyst, which is applied in the direction of nanotechnology, structural parts, electrical components, etc., and can solve unsatisfactory problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

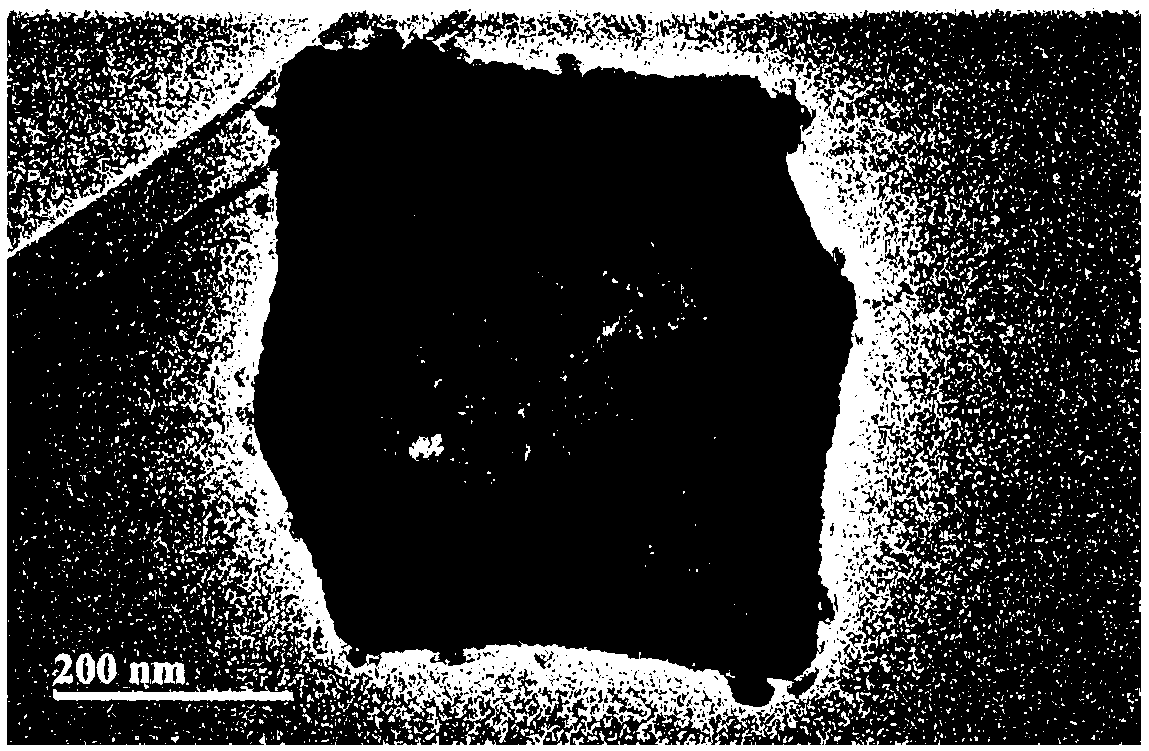

[0061] This embodiment provides an alloy nanocage catalyst and a preparation method thereof, the catalyst includes an alloy of a noble metal and a transition metal, the noble metal includes palladium, and the transition metal includes copper, wherein the mass fraction of the transition metal copper is 20wt %;

[0062] The catalyst has an octahedral hollow nano-cage structure with a particle diameter of 525nm and a wall thickness of 40nm.

[0063] The preparation method of described catalyst comprises the following steps:

[0064] (1) Disperse 20 mg of octahedral cuprous oxide with a particle size of 500 nm in 20 mL of water to form a dispersion liquid, add 130 mg of PVP, and stir for 10 min to obtain a mixed liquid;

[0065] (2) Adding 13.88mL of chloropalladic acid with a concentration of 10mM to the mixed solution obtained in step (1) to react, the reaction temperature is 30°C, and the reaction time is 20min to obtain a palladium-copper alloy;

[0066] (3) Add 1mmol acetic...

Embodiment 2

[0070] This embodiment provides an alloy nanocage catalyst and a preparation method thereof, the catalyst includes an alloy of a noble metal and a transition metal, the noble metal includes platinum, and the transition metal includes copper, wherein the mass fraction of the transition metal copper is 30wt %;

[0071] The catalyst has an octahedron hollow nano-cage structure with a particle diameter of 320nm and a wall thickness of 30nm.

[0072] The preparation method of described catalyst comprises the following steps:

[0073] (1) Disperse 50 mg of octahedral cuprous oxide with a particle size of 300 nm in 75 mL of water to form a dispersion liquid, add 100 mg of PVP, and stir for 15 min to obtain a mixed liquid;

[0074] (2) Adding 40mL of chloroplatinic acid with a concentration of 15mM to the mixed solution obtained in step (1) to react, the reaction temperature is 20°C, and the reaction time is 30min to obtain a platinum-copper alloy;

[0075] (3) Add 5mmol hydrochlori...

Embodiment 3

[0079] This embodiment provides an alloy nanocage catalyst and a preparation method thereof. The catalyst includes an alloy of a noble metal and a transition metal, the noble metal includes palladium and ruthenium, and the transition metal includes copper, wherein the mass fraction of the transition metal copper is is 10wt%;

[0080] The catalyst has an octahedral hollow nano-cage structure with a particle diameter of 780nm and a wall thickness of 50nm.

[0081] The preparation method of described catalyst comprises the following steps:

[0082] (1) Disperse 70 mg of octahedral cuprous oxide with a particle size of 750 nm in 20 mL of water to form a dispersion, add 160 mg of PVP, and stir for 20 minutes to obtain a mixed solution;

[0083](2) in the mixed solution that step (1) obtains, add the chloropalladic acid and chlororuthenic acid mixed solution 80mL that concentration is 2mM, wherein, chloropalladic acid and chlororuthenic acid volume ratio are 1:1, react, so Said re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com