Preparation method of transition metal doped nickel-based metal organic framework three-dimensional electrode material, product and application thereof

A transition metal, organic framework technology, applied in the field of preparation of transition metal-doped nickel-based metal-organic framework three-dimensional electrode materials, can solve the problems of destroying the original structure of MOF materials, agglomeration of metal nodes, loss of organic ligands, etc. The effect of catalytic reaction resistance, reducing overpotential, increasing conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

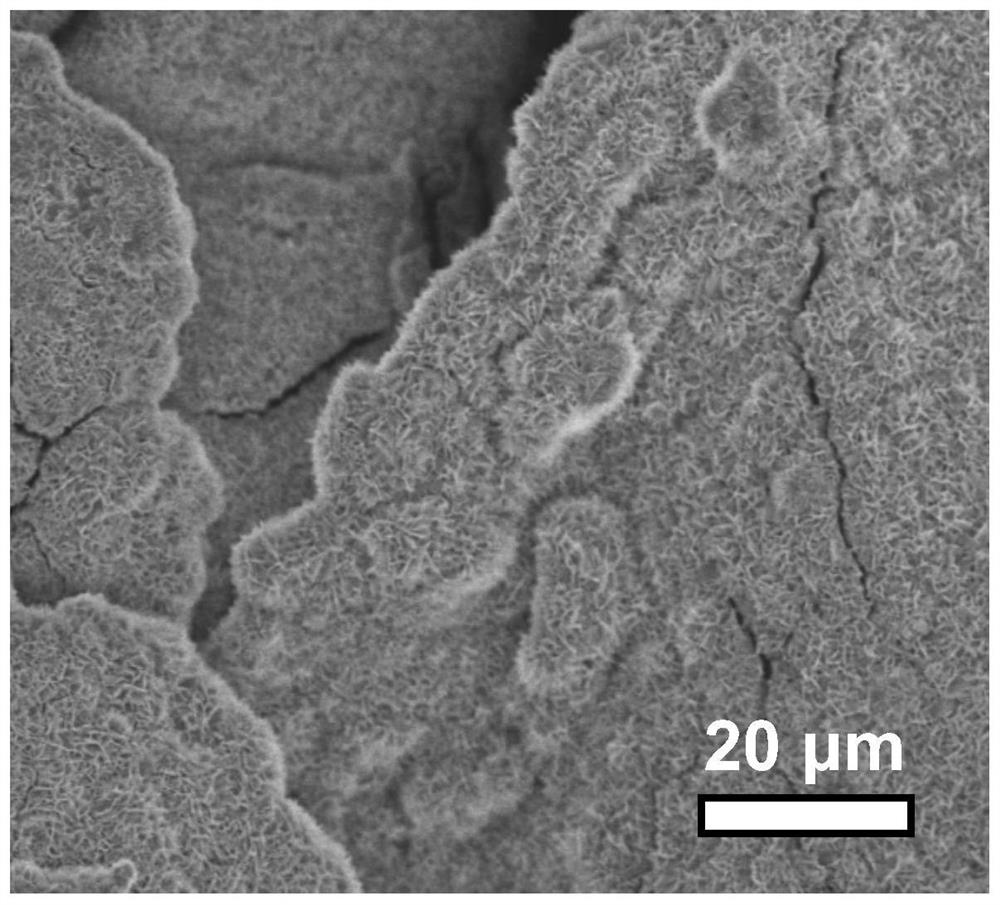

[0037] (1) Preparation of three-dimensional conductive graphite substrate

[0038]The graphite sheet was ultrasonically cleaned with acetone, ethanol and ultrapure water for 20 minutes, dried in an oven at 60°C for 4 hours, and then the graphite sheet was used as the working electrode, the platinum sheet was used as the counter electrode, and the concentrated sulfuric acid was used as the electrolyte. The graphite sheet was electrochemically oxidized and peeled off for 1 min. After the peeling, it was washed with a large amount of ultrapure water and dried in an oven at 60°C for 4 hours to obtain a three-dimensional graphite substrate;

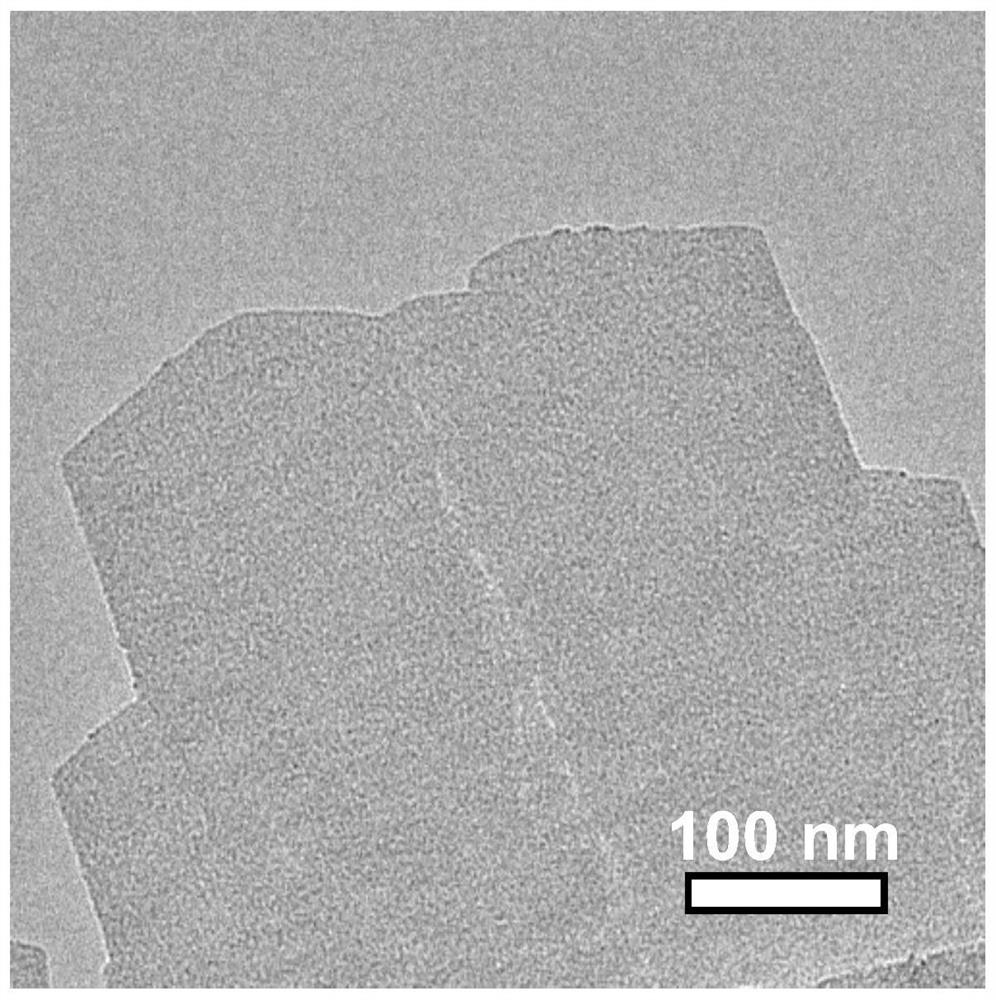

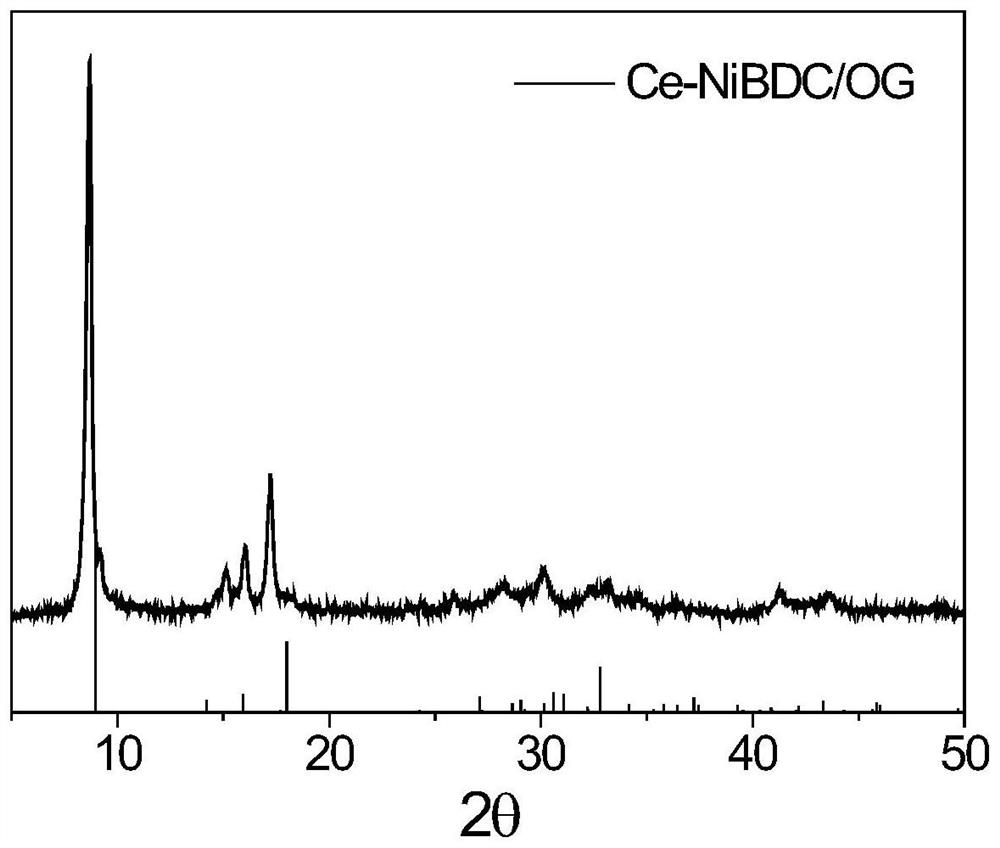

[0039] (2) Preparation of cerium-doped nickel-based metal-organic framework three-dimensional electrode materials

[0040] First measure 16mL of DMF, 1mL of ethanol and 1mL of ultrapure water as a mixed solvent, then weigh 119mg of nickel chloride hexahydrate, 6.5mg of cerium nitrate hexahydrate and 116mg of terephthalic acid, add them to the ...

Embodiment 2

[0053] According to the preparation method in Example 1, the difference is that the amount of cerium nitrate hexahydrate in step (2) is 2 mg, and the cerium-doped nickel-based metal organic framework three-dimensional electrode material is prepared.

[0054] The prepared cerium-doped nickel-based metal-organic framework three-dimensional electrode material exhibited an overpotential of 293 mV in an alkaline electrolyte.

Embodiment 3

[0056] According to the preparation method in Example 1, the difference is that the amount of cerium nitrate hydrate in step (2) is 13 mg, and the cerium-doped nickel-based metal organic framework three-dimensional electrode material is obtained.

[0057] The prepared cerium-doped nickel-based metal-organic framework three-dimensional electrode material exhibits an overpotential of 280 mV in an alkaline electrolyte.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com