A kind of hot working forming method of precipitation hardening stainless steel plate parts

A technology of precipitation hardening and thermal processing, which is applied in the field of thermal processing of precipitation hardening stainless steel plate parts, can solve the problems of high strength, low pass rate of finished parts, large deformation resistance, etc., and achieve obvious social benefits and significant Economic benefits, high deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

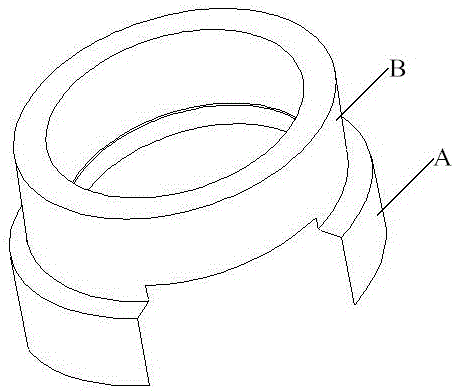

[0014] The structure of the dome parts of the aero-engine is as complex as figure 1 As shown, the blanking, roll bending and welding steps are included in the design of the part forming process. In this embodiment, the following steps are carried out when it is thermally processed and formed:

[0015] (1) For parts made of welded precipitation-hardening stainless steel plates, keep warm at 820°C for 2h, air-cool to room temperature, then keep warm at 600°C for 4h, and air-cool to room temperature;

[0016] (2) Heating parts that have been air-cooled to room temperature to 700°C;

[0017] (3) Heating the forming mold to 300°C for bulging to obtain the final formed precipitation-hardening stainless steel plate parts.

Embodiment 2

[0022] The structure of the bent pipe part of the aero-engine is complex, and the design process of the part includes blanking, rolling and welding steps. In this embodiment, the following steps are followed when it is hot-processed and formed:

[0023] (1) For parts made of welded precipitation-hardening stainless steel plates, keep warm at 810°C for 2h, air-cool to room temperature, then keep warm at 610°C for 4h, and air-cool to room temperature;

[0024] (2) Heating parts that have been air-cooled to room temperature to 720°C;

[0025] (3) Heating the forming mold to 280°C for bulging to obtain the final formed precipitation-hardened stainless steel plate parts. The obtained parts have no cracks on the surface, and the strength meets the design requirements, and they are qualified products after testing.

Embodiment 3

[0027] The structure of the dome part of the aero engine is complex, and the forming process of the part includes blanking, bending and welding steps. In this embodiment, the following steps are carried out when it is thermally processed and formed:

[0028] (1) For parts made of welded precipitation-hardening stainless steel plates, keep warm at 830°C for 2h, air-cool to room temperature, then keep warm at 590°C for 4h, and air-cool to room temperature;

[0029] (2) Heating parts that have been air-cooled to room temperature to 680°C;

[0030] (3) Heating the forming mold to 320°C for bulging to obtain the final formed precipitation-hardening stainless steel plate parts. The obtained parts have no cracks on the surface, and the strength meets the design requirements, and they are qualified products after testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap