Novel safe maintenance-free oil heating roller body

A maintenance-free, oil-heating technology, which is applied in ironing machines, washing devices, textiles and papermaking, etc., can solve the problems of low energy utilization, high oil pressure and oil temperature in boiler rooms, and low roller surface temperature. To meet the use requirements and other issues, to achieve the effect of ensuring service life, preventing heat transfer oil leakage, and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

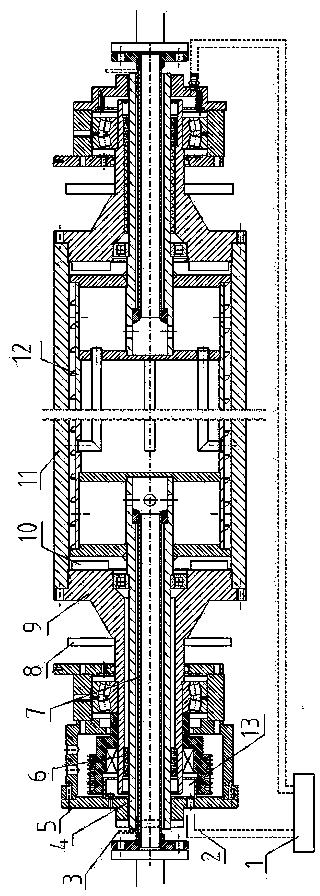

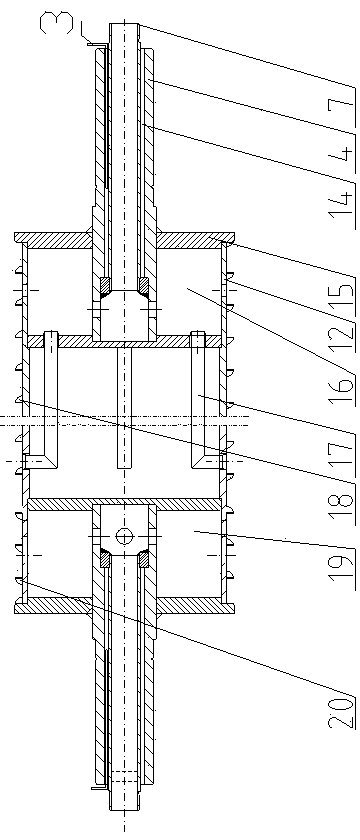

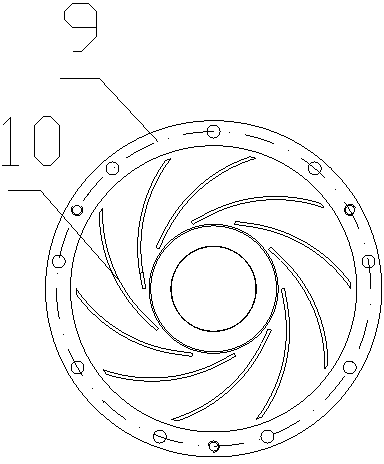

[0020] A new type of safe and maintenance-free oil heating roller body, including two shaft heads 9 on the left and right and a middle roller shell 11, an inner liner 12 is arranged inside the middle roll shell, and the ring shape between the outer surface of the inner liner 12 and the roll shell 11 The cavity is a heating chamber through which heat-conducting oil flows. The outer surface of the inner tank 12 is provided with a heat balance mechanism, and the two ends of the inner tank 12 are provided with end plates 15, and a dynamic seal is formed between the outer edge of the end plate 15 and the inner surface of the roller shell. structure, a number of oil throwing blades 10 are arranged between the end plate 15 and the shaft head 9, and two chambers are respectively arranged in the inner tank close to the two end plates, one chamber is the oil inlet chamber 16, and the other chamber is It is the oil outlet chamber 19, both the inlet and outlet chambers communicate with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com