Anti-dazzle circular daily ceramic device applique out-of-bound detection method

A detection method and anti-glare technology, applied in the field of image processing, can solve problems affecting processing and accuracy, low detection efficiency, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The following describes how to use the entire circular ceramic device pattern out-of-bounds detection scheme.

[0054] Place the industrial camera and light source directly above the inspected ceramic device, and then use computer control to obtain images of the ceramic. In order to better distinguish the inspected ceramics from the background, white ceramics can be placed on the black production line. In order to prevent the occurrence of ceramic glare, adjust the ambient light to a weak level. The following is the implementation method of ceramic applique boundary defect detection:

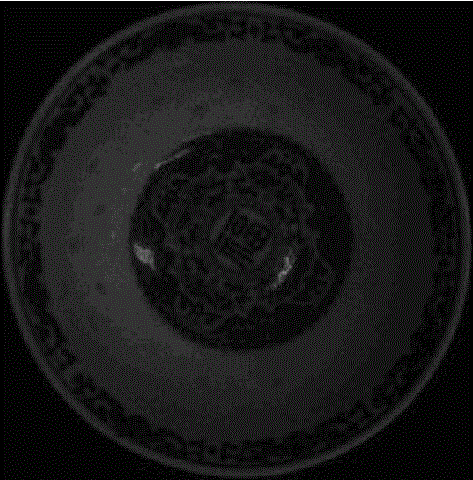

[0055] 1) Use the camera to obtain the original ceramic grayscale image under low light conditions, such as figure 1 shown;

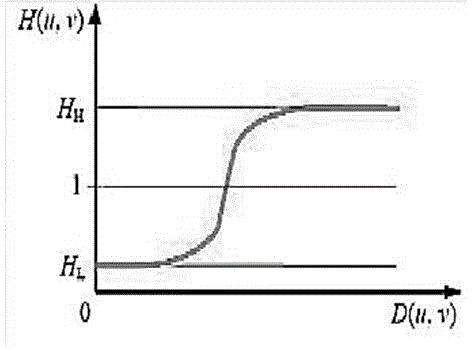

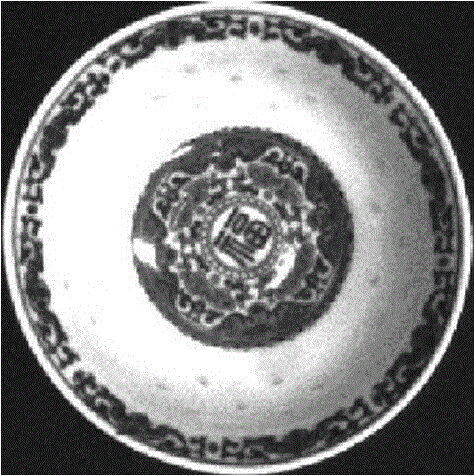

[0056] 2) Design the transfer function of homomorphic filtering And give the corresponding parameter values, such as high-frequency weight , low frequency weight , cut-off frequency ,Such as figure 2 As shown, and for the original ceramic grayscale ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com