Constant volume combustion bomb and liquid fuel combustion performance testing method

A technology of constant-volume incendiary bombs and liquid fuels, which is applied in the direction of using combustion for chemical analysis, and can solve problems such as the inability to accurately control the air-fuel ratio of volume bombs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

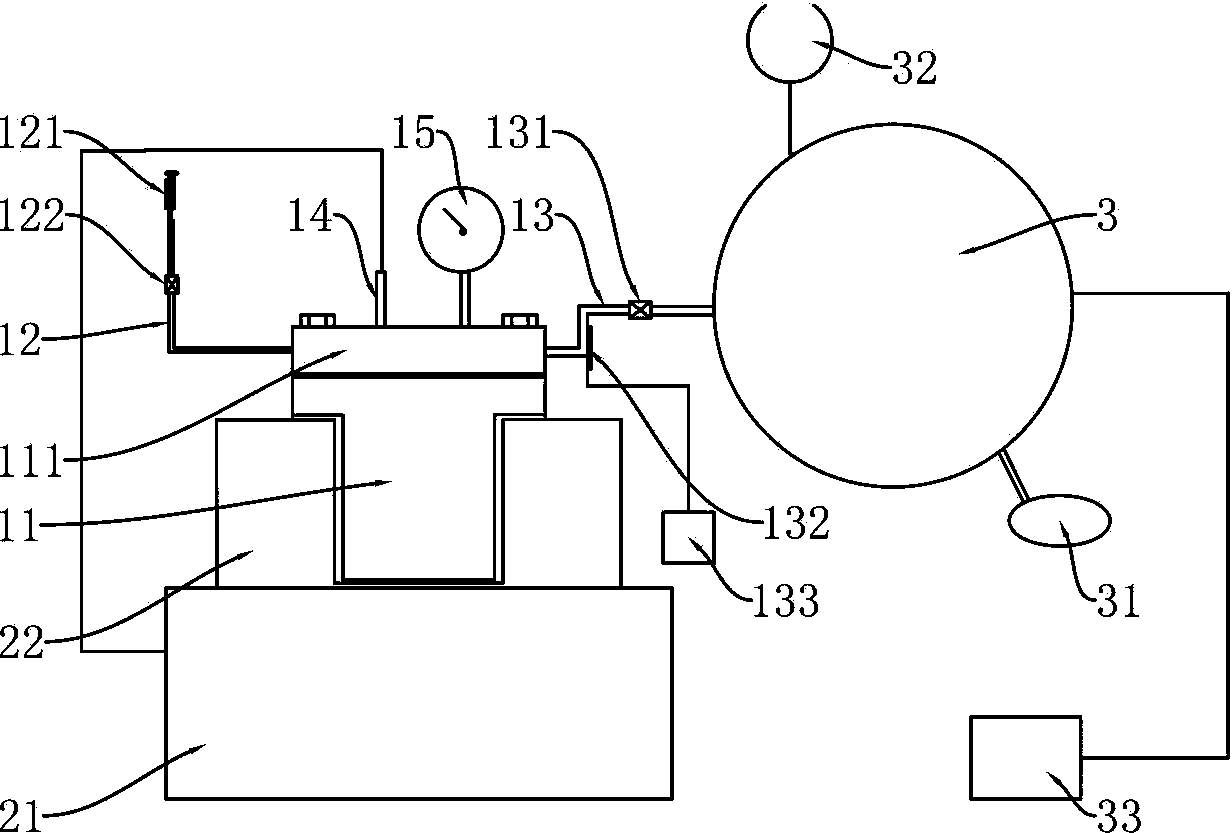

[0052] see Figure 1 to Figure 2. The constant-volume incendiary bomb described in this embodiment consists of an evaporator 11 , a heating device and an incendiary bomb 3 . The incendiary bomb control device 33 is signal-connected with the incendiary bomb 3 for controlling the ignition test. Incendiary bomb 3 is a known product, and the incendiary bomb selected in this embodiment is Beijing Institute of Technology BITEC-RD-QX-350. The incendiary bomb 3 is equipped with a second pressure detection device 32 for detecting the internal pressure of the incendiary bomb. The second pressure detection device 32 adopts a high-precision electronic pressure gauge. This embodiment provides an electronic pressure gauge with a model of DELTA DPA01M-P-100-100KPa, and its accuracy is 0.05% FPS.

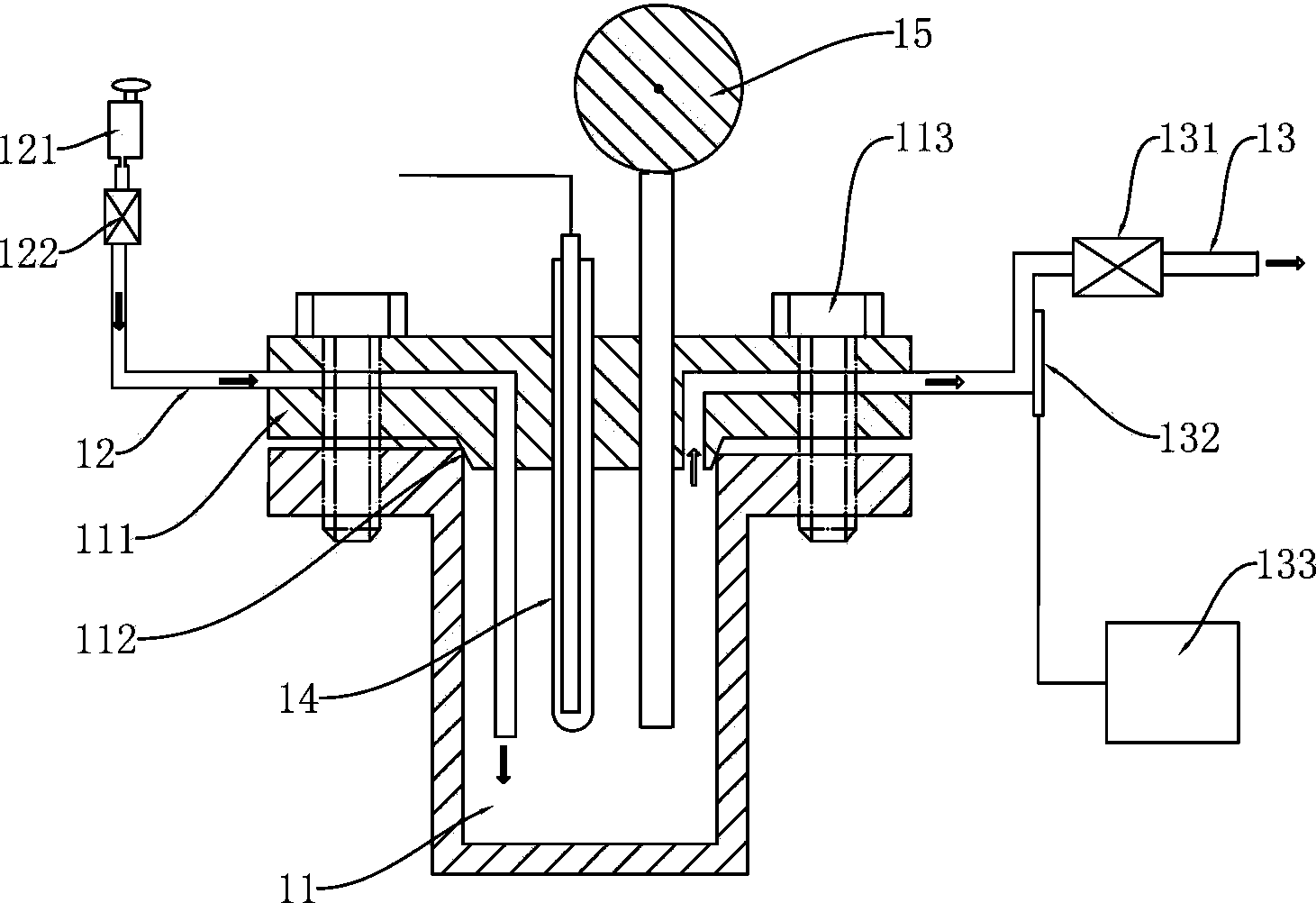

[0053] The evaporator 11 is a closed container, the evaporator is provided with a feed inlet and a discharge port, and is equipped with a first temperature sensor 14 for detecting the internal t...

Embodiment 2

[0062] image 3 with Figure 4 The effect of using the constant volume incendiary bomb gasoline combustion performance test experiment described in embodiment 1 is shown.

[0063] This embodiment is carried out on the basis of the constant volume incendiary bomb described in Embodiment 1, and the liquid fuel is gasoline.

[0064] The evaporator is placed on the heating device, and the heating device heats the evaporator to above 600K. The final distillation temperature of gasoline is 468K. Therefore, setting the heating temperature at 480K and adding that the evaporator has been evacuated can ensure that the gasoline is completely evaporated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com