Heat-conducting rubber sheet fixing structure and end socket

A fixed structure, heat-conducting adhesive technology, applied to structural parts, sealing materials, electrical components, etc., can solve problems such as ear glue burns, affecting thermal conductivity, affecting production efficiency, etc., to achieve rapid replacement, good thermal conductivity, and close contact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

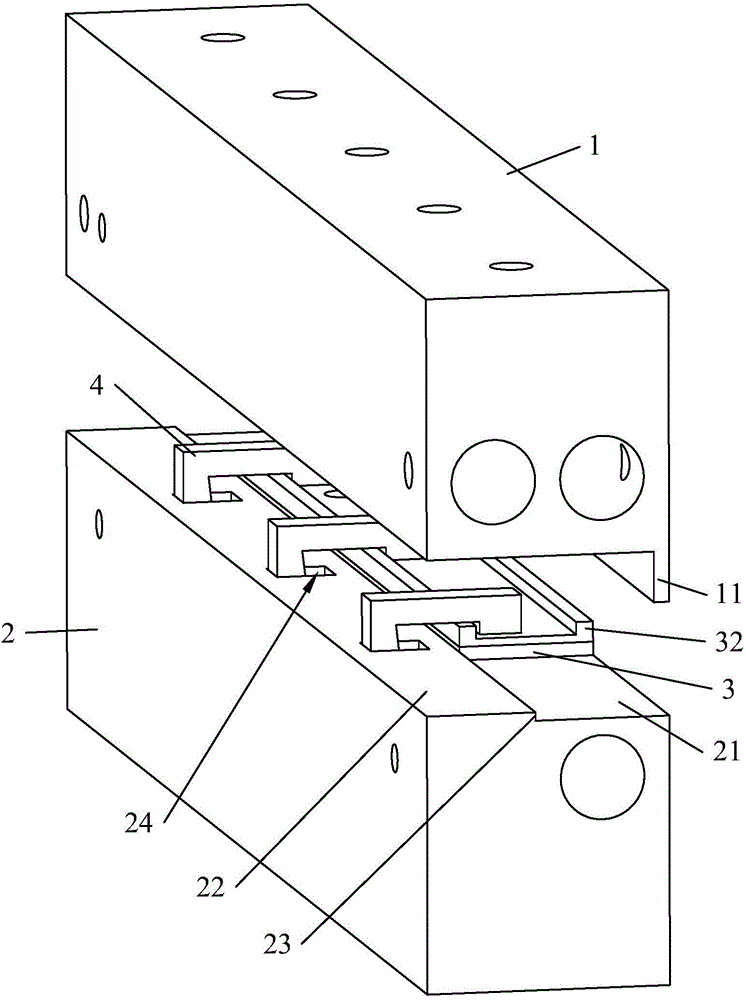

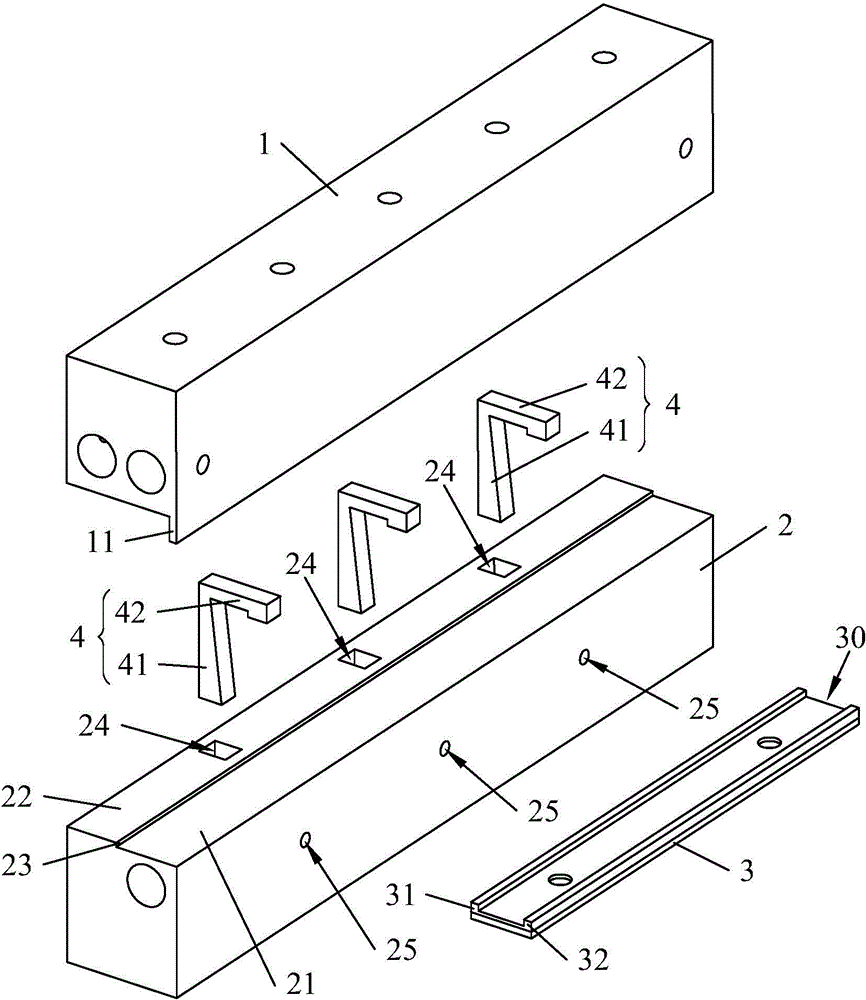

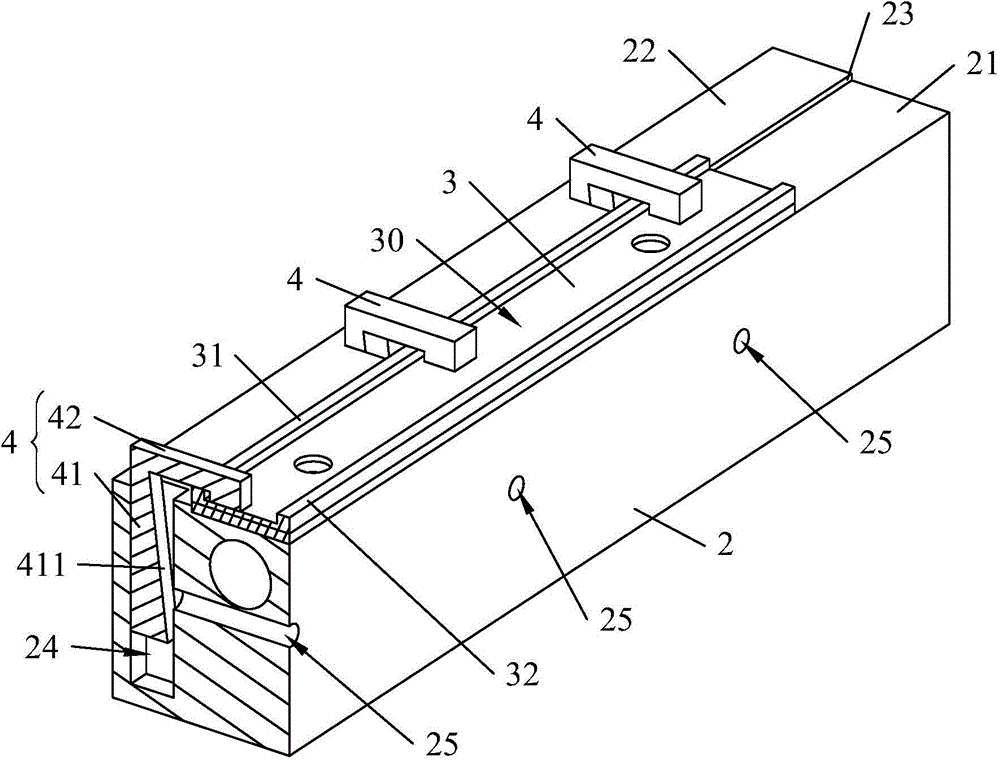

[0021] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0022] Such as Figure 1 to Figure 3 As shown, the present invention discloses a sealing head, which includes an upper sealing head 1, a lower sealing head 2, a heat-conducting rubber plate 3 and a heat-conducting rubber plate 3 detachably fixed on the top surface of the lower sealing head 2. Glue plate fixed structure. The fixing structure of the thermally conductive rubber plate includes three positioning pieces 4 and three screws (not shown in the figure).

[0023] The upper sealing head 1 and the lower sealing head 2 are vertically opposite to each other, and the lower end of the upper sealing head 1 is formed with an upper packaging flange 11 protruding downward.

[0024] The top surface of the lower head 2 includes a first plane 21 and a second plane 22 protruding relative to the first plane 21, a vertical plane 23 is connected between the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap